Procedure

Proceed as follows to implement a user acknowledgment for global reintegration:

1. Insert operation "ACK_GL" in that F-runtime group, whose F-I/O should be globally

acknowledged by the user acknowledgment.

2. In operation "ACK_GL", assign input "ACK_GLOB" to the input of the acknowledgment

button.

3. If necessary, carry out the optional steps:

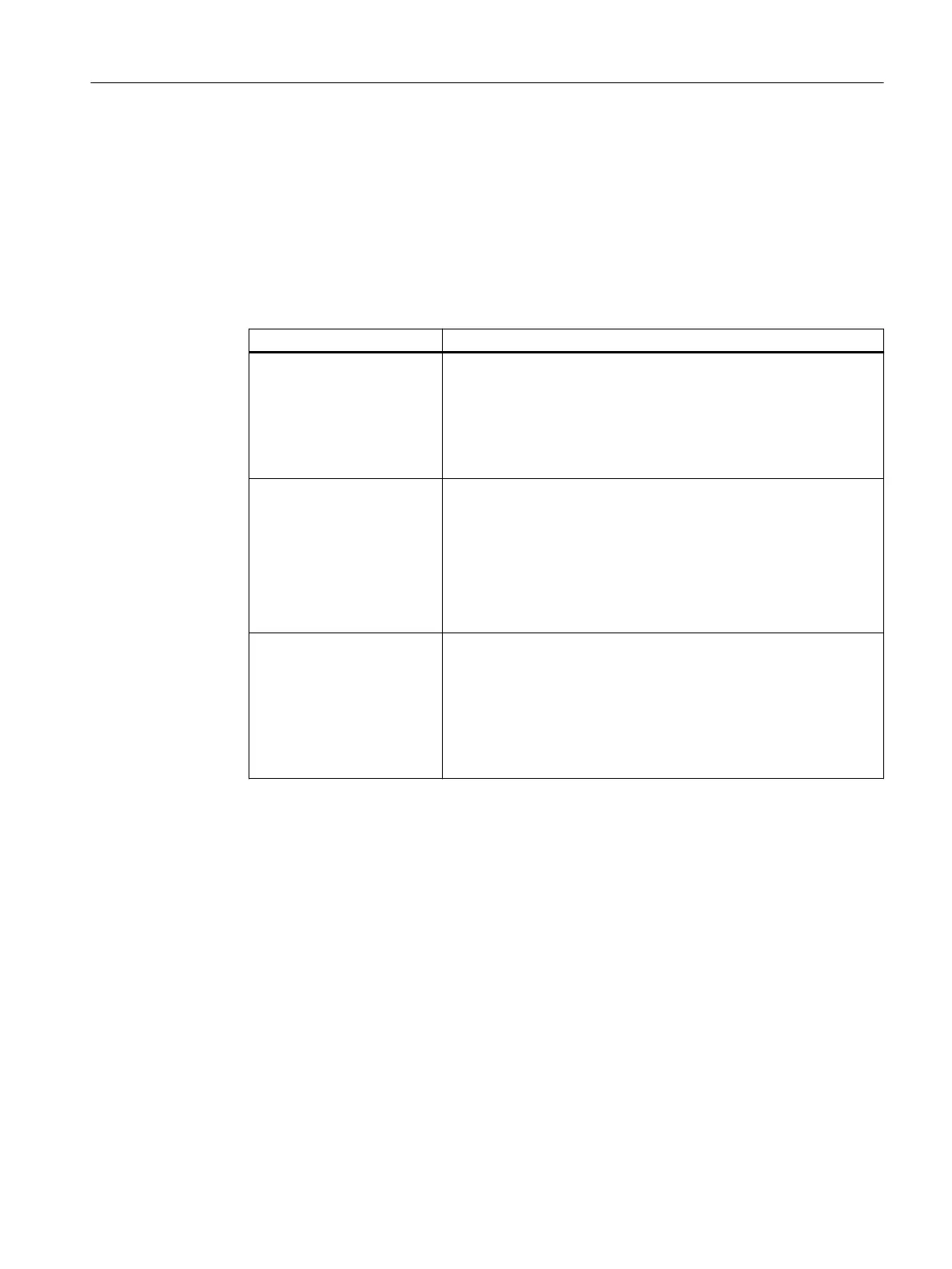

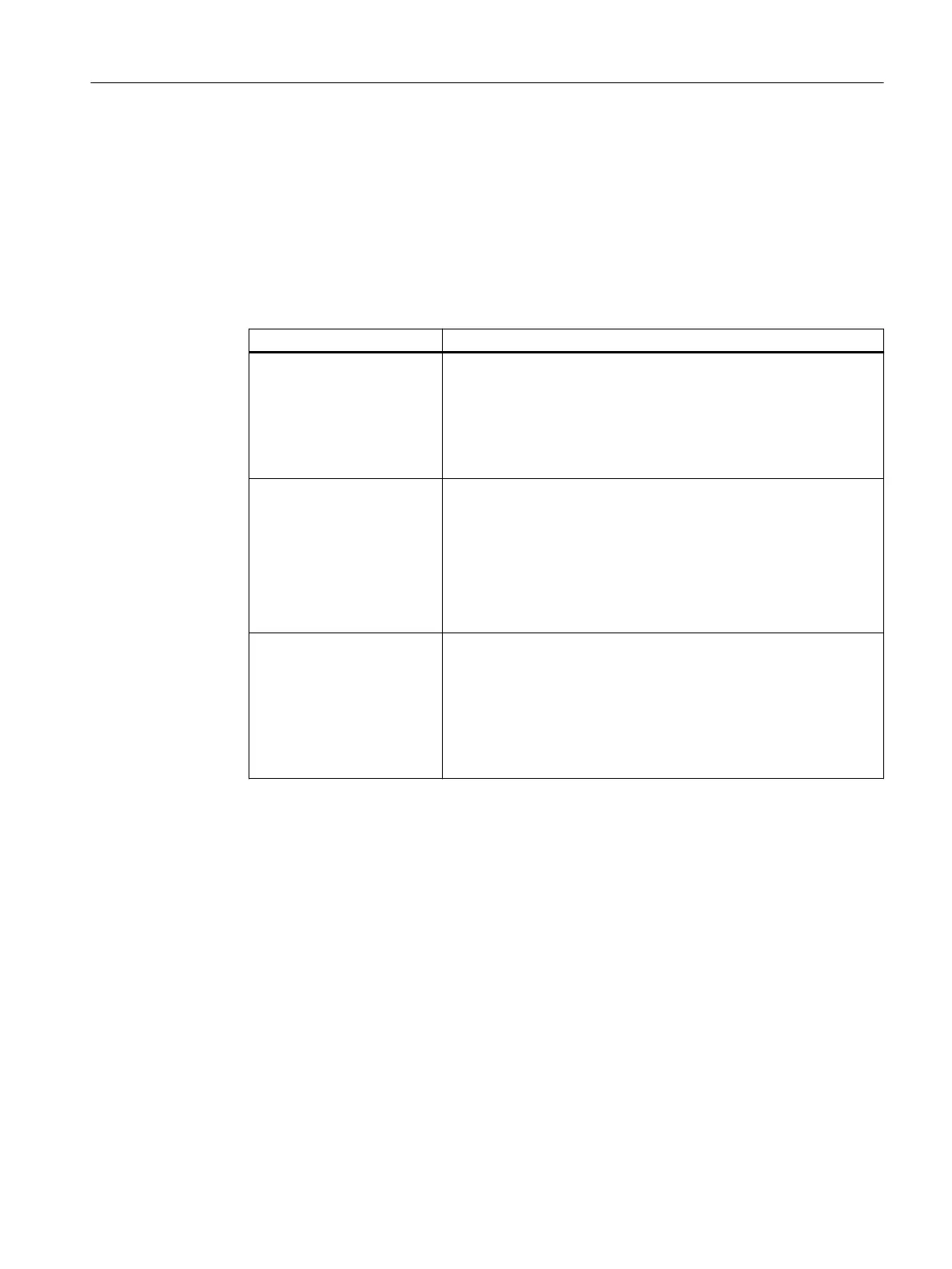

Setting Procedure

Evaluation of the acknowl‐

edgment request

You can evaluate the F-I/O DB tag "ACK_REQ" in the standard user

program or on an operation and monitoring system, to interrogate as

to whether a user acknowledgment is required.

● ACK_REQ = 0: No acknowledgment request

● ACK_REQ = 1: Acknowledgment request for reintegration (this is

set by the F-system after the fault has been resolved)

Controlling a signal light or

output of a signal

In the case of a fault, you can control a signal light and/or output

messages/signals in the standard user program, by evaluating the

following:

● F-I/O DB tags:

– QBAD

– DIAG

● Diagnostics buffer of the F-PLC

Automatic or manual reinte‐

gration for F-I/O/channel

faults

You can parameterize the F-I/O DB tag "ACK_NEC" if, after an F-I/O/

channel fault, automatic reintegration should take place without user

acknowledgment.

● ACK_NEC = 1 (start value): User acknowledgment required

● ACK_NEC = 0: Automatic reintegration

A user acknowledgment is always required after a communication

error.

Parameterizing tags ACK_NEC = 0 is only permitted, if, from a safety-relevant perspective

automatic reintegration is permissible for the process involved.

(S010)

6.3.7 Acknowledging messages related to safety functions integrated in the drive

You program PROFIsafe acknowledgment in the safety program of the F-PLC by setting the

"Internal Event ACK" signal - separately for each drive object - via the PROFIsafe telegram

(S_STW1/S_STW2 bit 7).

Safety messages cannot be acknowledged collectively by the F-PLC, but instead have to be

individually acknowledged for each drive object. A falling edge of the "Internal Event ACK"

signal resets the status "Internal Event" in the particular drive, and thus acknowledges the fault.

Commissioning and configuring

6.3 Generating a safety program

Safety Integrated (with SINAMICS S120)

Commissioning Manual, 02/2020, A5E46305916B AB 237

Loading...

Loading...