5-43

4st 9.9/15/20 2008

6

Do not reuse.

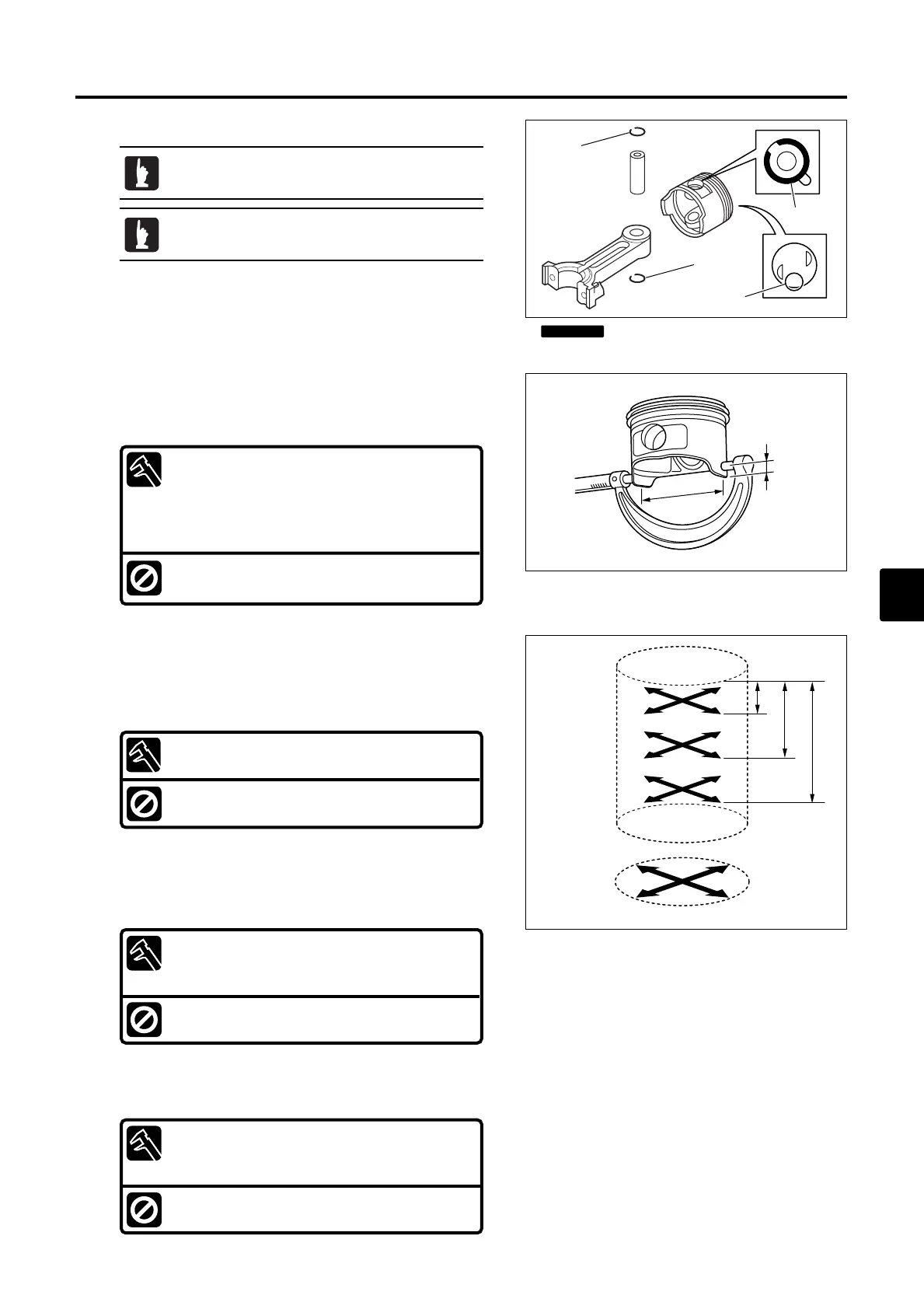

7. Remove piston pin clips 6 and piston pin, and then, piston.

Write cylinder number a on the mating piston.

Do not reuse piston pin clips. Be sure to replace

with new ones.

5

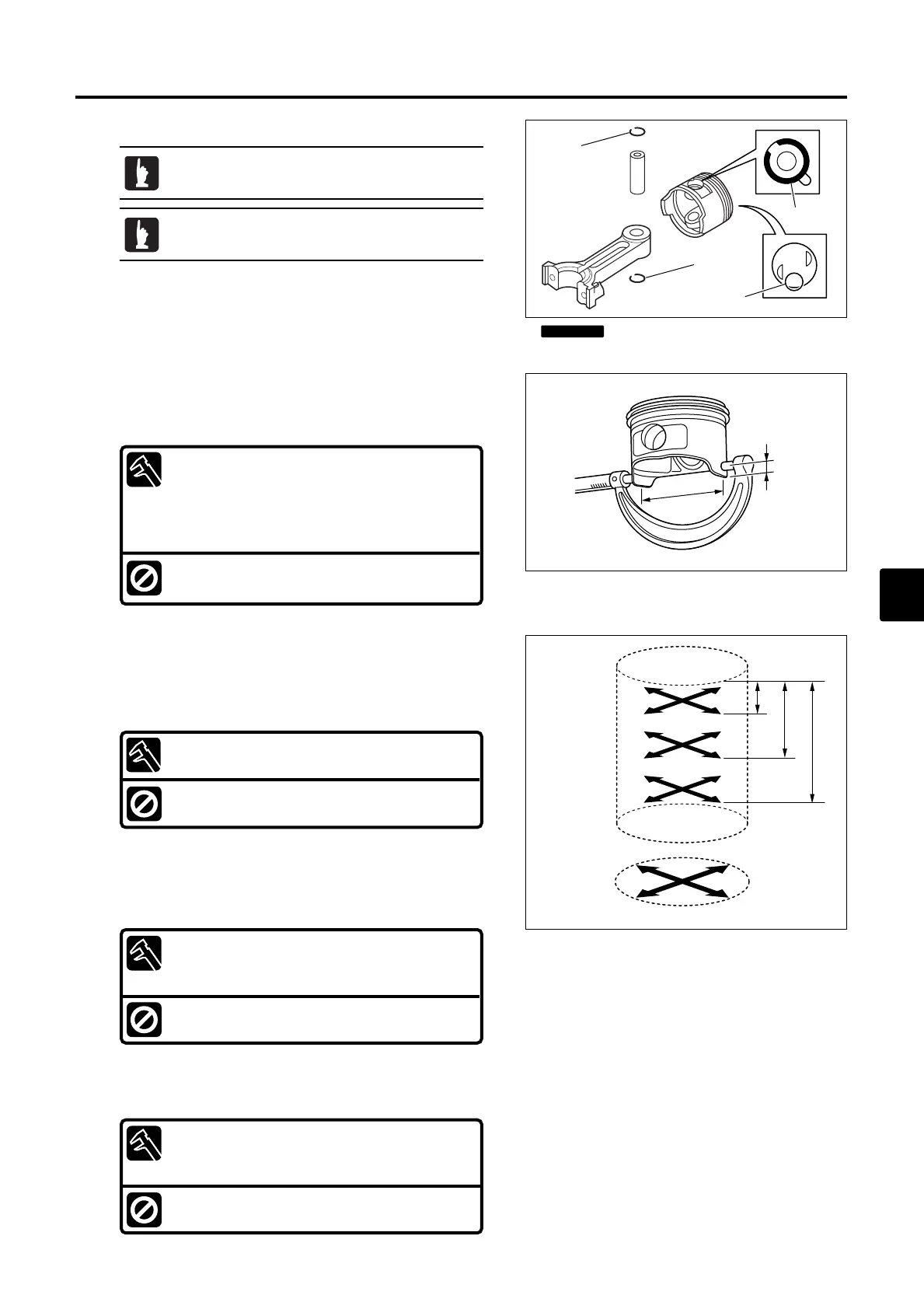

27) Inspection of Piston Outer Diameter

1. Measure piston outer diameter between points specified.

Replace if it is less than specified value.

Piston Outer Diameter a : Standard Value

60.96 mm (2.4000 in)

Measurement point b: on the line at right

angle to piston pin.

9mm (0.28 in) above piston skirt bottom

Functional Limit :

60.90 mm (2.3976 in)

d

e

D2

D4

D6

D1

D3

D5

a

b

c

28)

Inspection of Cylinder Inner Diameter

1. Measure cylinder inner diameters (D1 to D6) at a, b and c

in crank shaft directions d (D1, D3 and D5 respectively),

and in crank web directions e (D2, D4 and D6 respectively).

2. Obtain taper through calculation described below. Replace

cylinder block if it is over specified value.

Note : Measure at the maximum wear points.

Cylinder Inner Diameters (D1 to D6) : Standard Value

61.00 mm (2.4016 in)

Functional Limit :

Replace if over 61.06 mm (2.4039 in).

Taper Limit :

D1-D5 (direction d)

D2-D6 (direction e)

Functional Limit :

0.06 mm (0.0024 in)

a 15mm (0.6in)

b 35mm (1.4in)

c 55mm (2.2in)

d Crankshaft direction

e Crank web direction

3.

Obtain out-of-roundness through calculation described below.

Replace cylinder block if out-of-roundness is over specified value.

Out-of-roundness Limit :

D2-D1 (measuring point a)

D6-D5 (measuring point c)

Functional Limit :

0.06 mm (0.0024 in)

E_MFS20C_ch05_090105.qxd 09.1.20 5:25 PM ページ 43

Loading...

Loading...