5-48

Power Unit

4st 9.9/15/20 2008

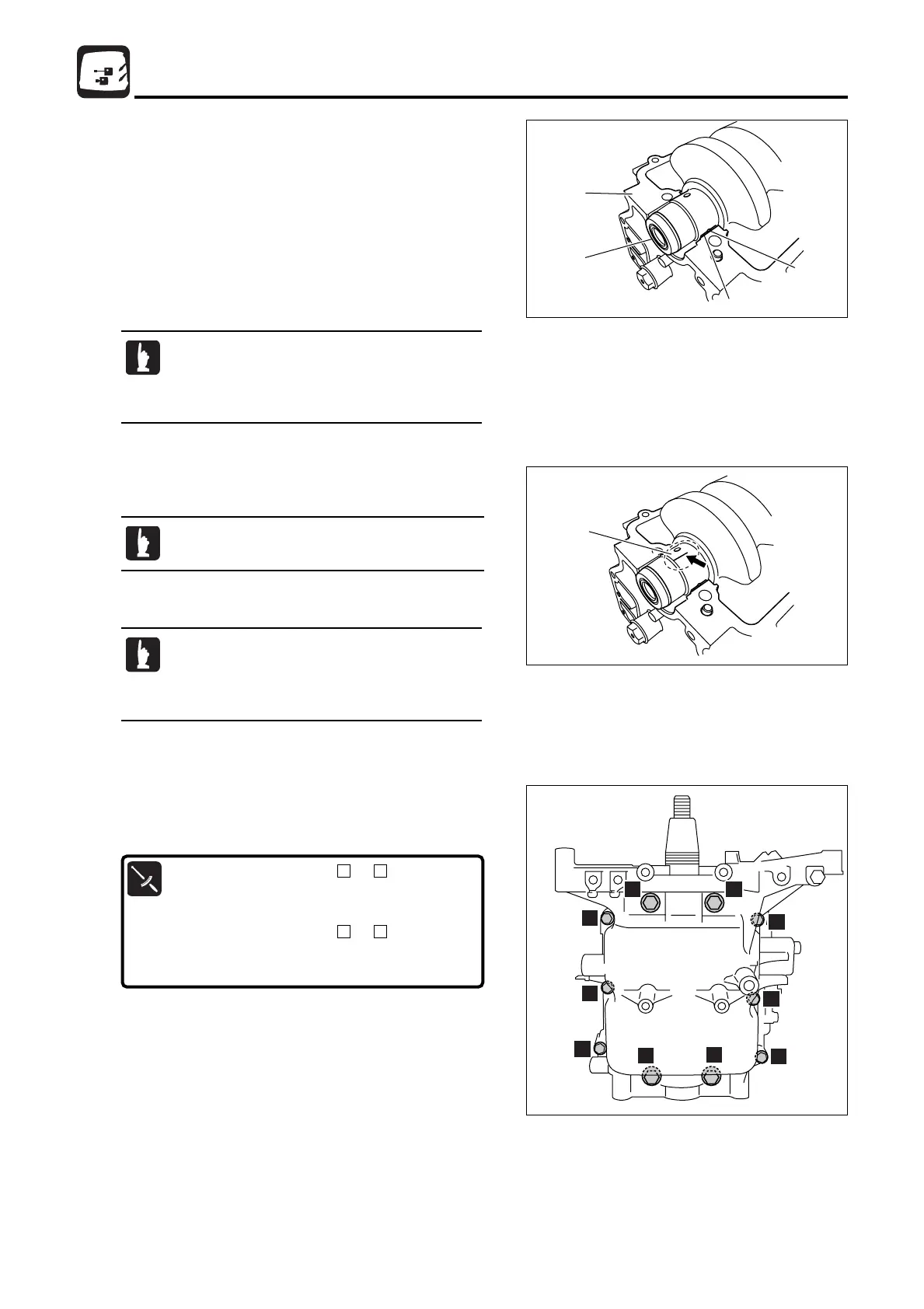

37) Crankshaft Main Journal Oil

Inspection of clearance

1. Clean bearings, crankshaft main journal, and bearing

installation areas of crank case and cylinder block.

2. Place cylinder block on the work bench with cylinder head

side facing downward.

3. Install bearing 1 and crankshaft 2 to cylinder block 3.

4. Place plasti-gauge 4 on each crankshaft main journal

parallel to crankshaft.

5. Install bearings to crank case.

6. Install crank case to cylinder block.

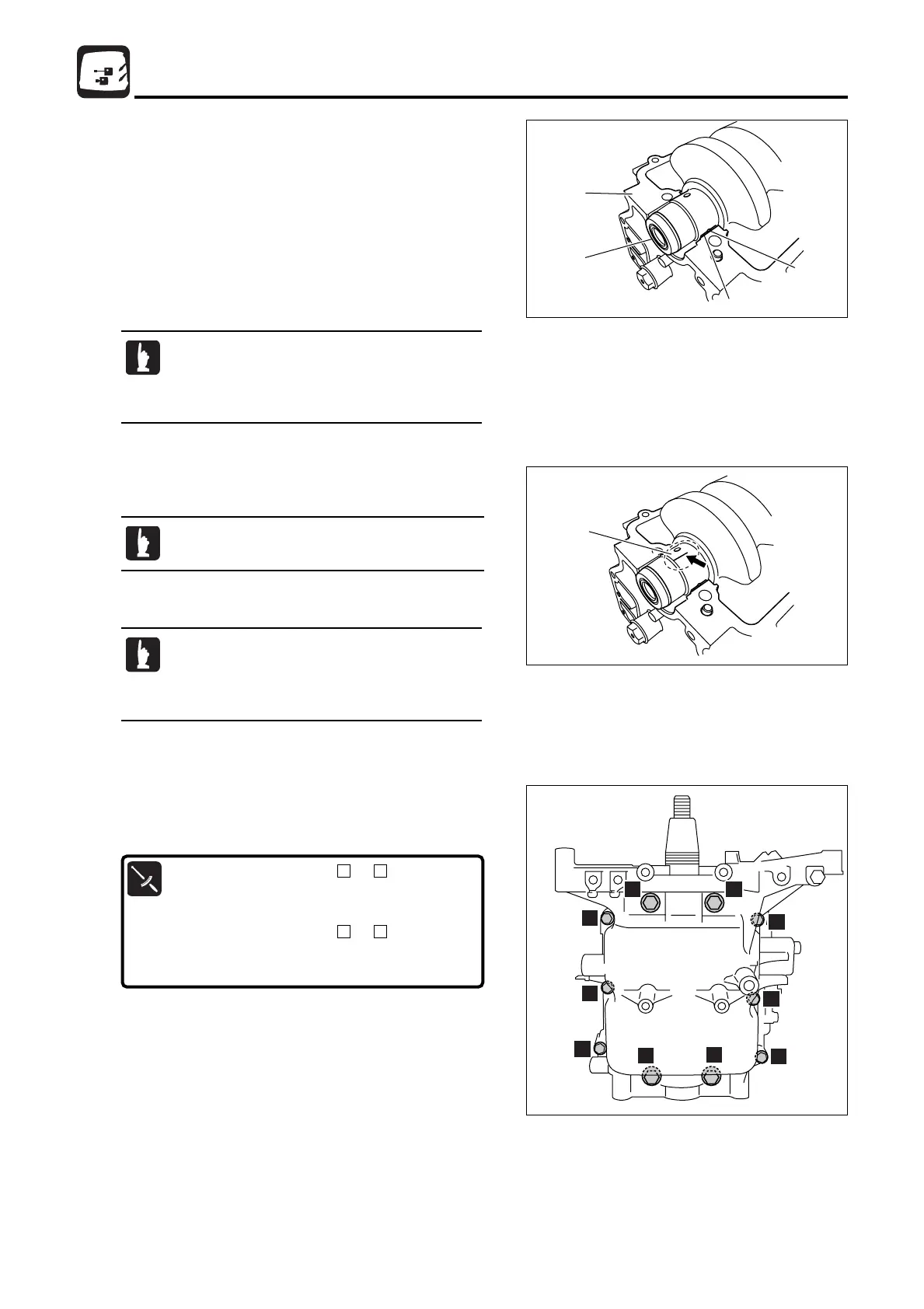

7. Tighten crankcase bolts in the order of numbers shown in

two steps to specified torque.

Crank Case Bolts (M8) : to

First Tightening Torque : 10 N · m (7 lb · ft) [1.0 kgf · m]

Second Tightening Torque : 23.5 N · m (17 lb · ft) [2.4 kgf · m]

Crank Case Bolts (M6) : to

First Tightening Torque : 6 N · m (4 lb · ft) [0.6 kgf · m]

Second Tightening Torque : 11.5 N · m (8.5 lb · ft) [1.2 kgf · m]

10

5

41

2

a

1

3

4

1 2

8

6

10

3

4

9

5

7

· Be sure that individual bearings are installed

to their original locations.

· Install bearings with their projection fit into

crank case groove.

Do not place plasti-gauge 4 on the oil hole of

crankshaft main journal.

· Be sure that individual bearings are installed

to their original locations.

· Install bearings with their projection a fit into

cylinder block groove.

E_MFS20C_ch05_090105.qxd 09.1.20 5:25 PM ページ 48

Loading...

Loading...