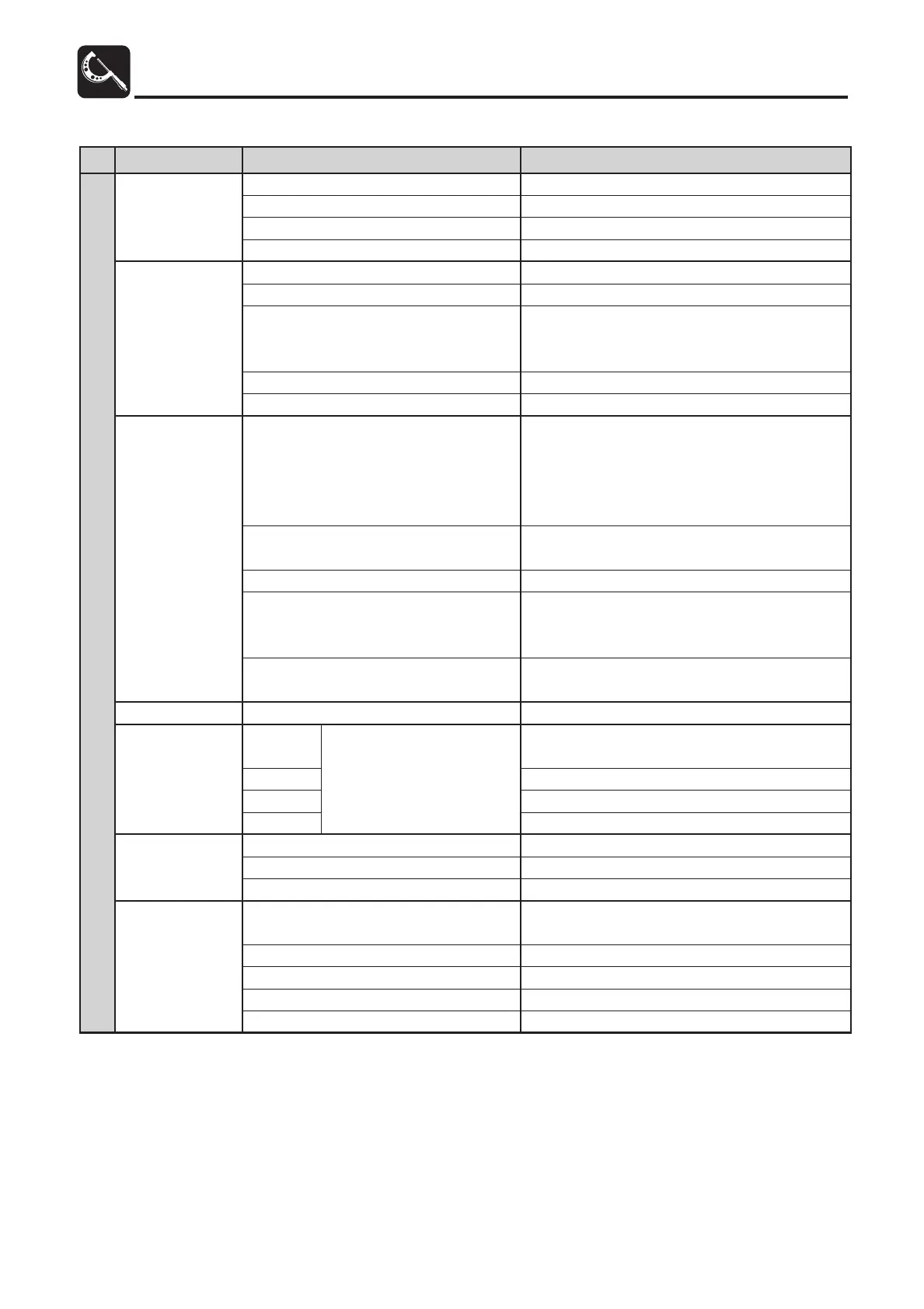

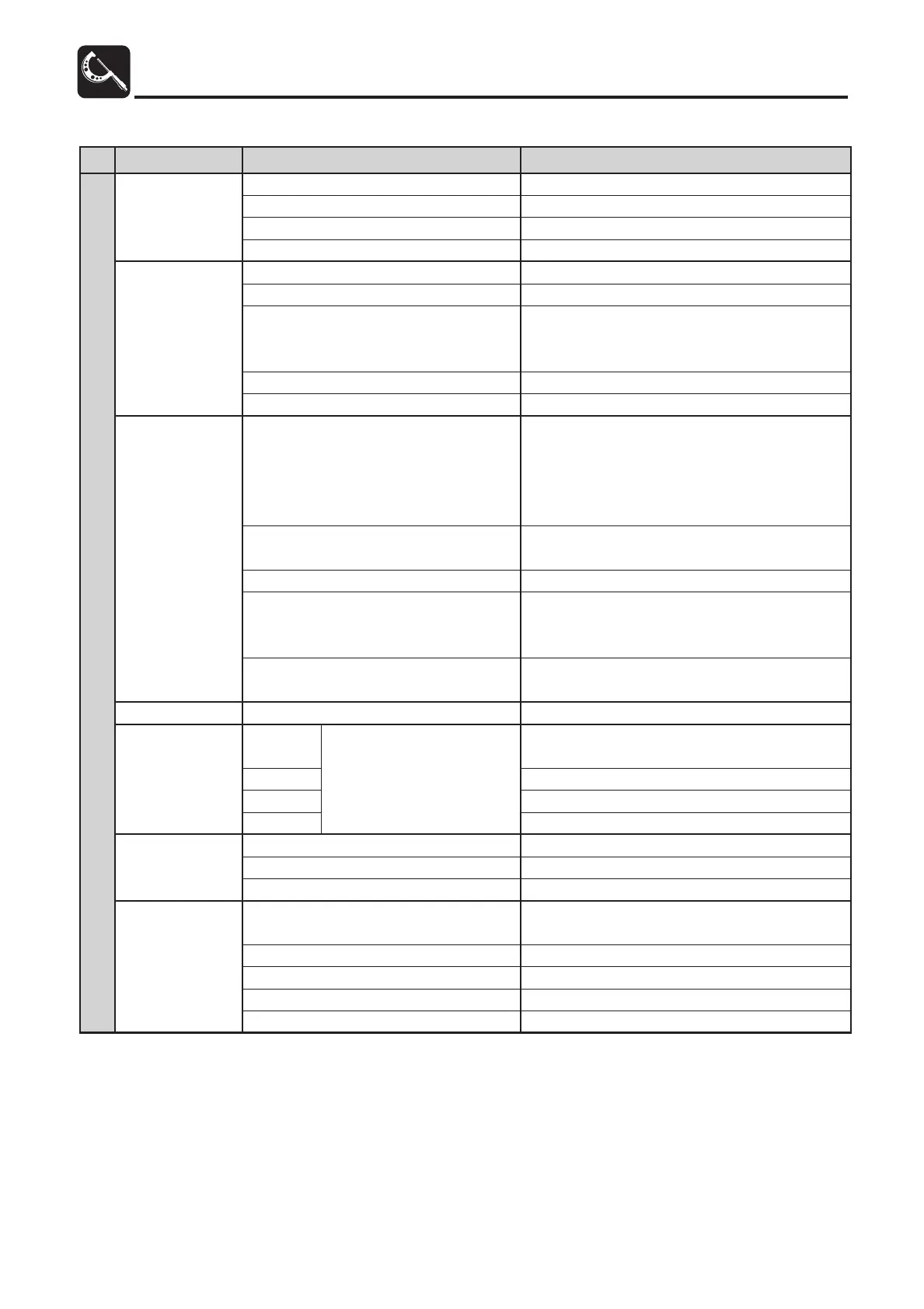

6. Maintenance Data

Part name Item Standard value

Engine parts

Cylinder head

Cylinder

Piston

Piston pin

Piston rings

Connecting rod

Crankshaft

Carbon deposition on combustion chamber wall

Deformation of mating faces and flaws

Corrosion of mating faces

Plugging of cooling water passages

Deposition on water jacket interior walls

Wear of bore : Measure bore by using cylinder gauge.

Seizing, and damage and wear of cylinder liner

Taper

Roundness

Deformation and damage of cylinder head mating faces

Engine anode

Outer diameter

Measure outer diameter at 9mm (0.35in)

above lower end of piston skirt.

(Measure at right angle to piston pin.)

· Piston clearance

Carbon deposition on piston crown and

in ring grooves

Flaws on sliding faces

Measure side clearance between piston

ring and ring groove.

Measure piston pin bore.

Piston pin clearance

Outer diameter

Ring end

gap

Top ring

Second ring

Oil ring

Small end bore

Big end oil clearance

Big end side clearance

Crankshaft runout: Support crankshaft at

journals of both ends by using V block.

Crank pin outer diameter

Main journal outer diameter

Metal bearing oil clearance

Crankshaft side clearance

61.00mm (2.4016in)

60.96mm (2.4000in)

0.020 - 0.055mm (0.00079 - 0.00217in)

Top ring 0.04 - 0.08mm (0.0016 - 0.0031in)

Second ring 0.03 - 0.07mm (0.0012 - 0.0028in)

Oil ring 0.05 - 0.15mm (0.0019 - 0.0059in)

0.002 - 0.012mm (0.00008 - 0.00047in)

16.00mm (0.6299in)

Ring gauge 61.000mm (2.40157in)

Top ring 0.15 - 0.30mm (0.0059 - 0.0118in)

Second ring 0.35 - 0.50mm (0.0138 - 0.0197in)

Oil ring 0.20 - 0.70mm (0.0079 - 0.0276in)

16.01mm (0.6303in)

0.015 - 0.041mm (0.00059 - 0.0161in)

0.10 - 0.25mm (0.0039 - 0.0098in)

To be less than 0.05mm (0.0020in)

at both ends and at the center.

29.98mm (1.1803in)

35.99mm (1.4169in)

0.012 - 0.044mm (0.00047 - 0.00173in)

0.1 - 0.3mm (0.004 - 0.012in)

Note : Measure ring end gap at

the top or bottom cylinder

bore that is worn little if

ring gauge is not available.

Loading...

Loading...