ELECTRICAL

6-18 Z580/Z593/Z595 Diesel Service Manual

6

How It Works

Testing

Clutch Coil Continuity Test

The PTO clutch is composed of three major compon-

ents; the fi eld, the clutch plate, and the friction plate.

The clutch plate always turns with the engine. The

fi eld is a coil of wire wound around an iron core, which

acts like an electromagnet when power is applied. The

friction plate is the only piece that can slide inward and

outward on the crankshaft axis. It is spring loaded away

from contact with the clutch plate. When the clutch is

not energized, the clutch plate rests against the brake

material opposite the clutch plate. When energized the

friction plate is drawn into the clutch plate magnetically

and the two rotate as one component.

5. The meter should read:

Warner clutch: 1.0 – 2.7 ohms,

Ogura clutch: 2.4 ohms

If the reading is above or below these readings, the

fi eld has failed and needs to be replaced. If the reading

falls within the specifi ed resistance, measure clutch coil

continuity (see below).

This test can be performed the same way on both the

Warner and Orgura clutches.

1. Disengage PTO.

2. Raise the seat and disconnect the negative battery

cable from the battery.

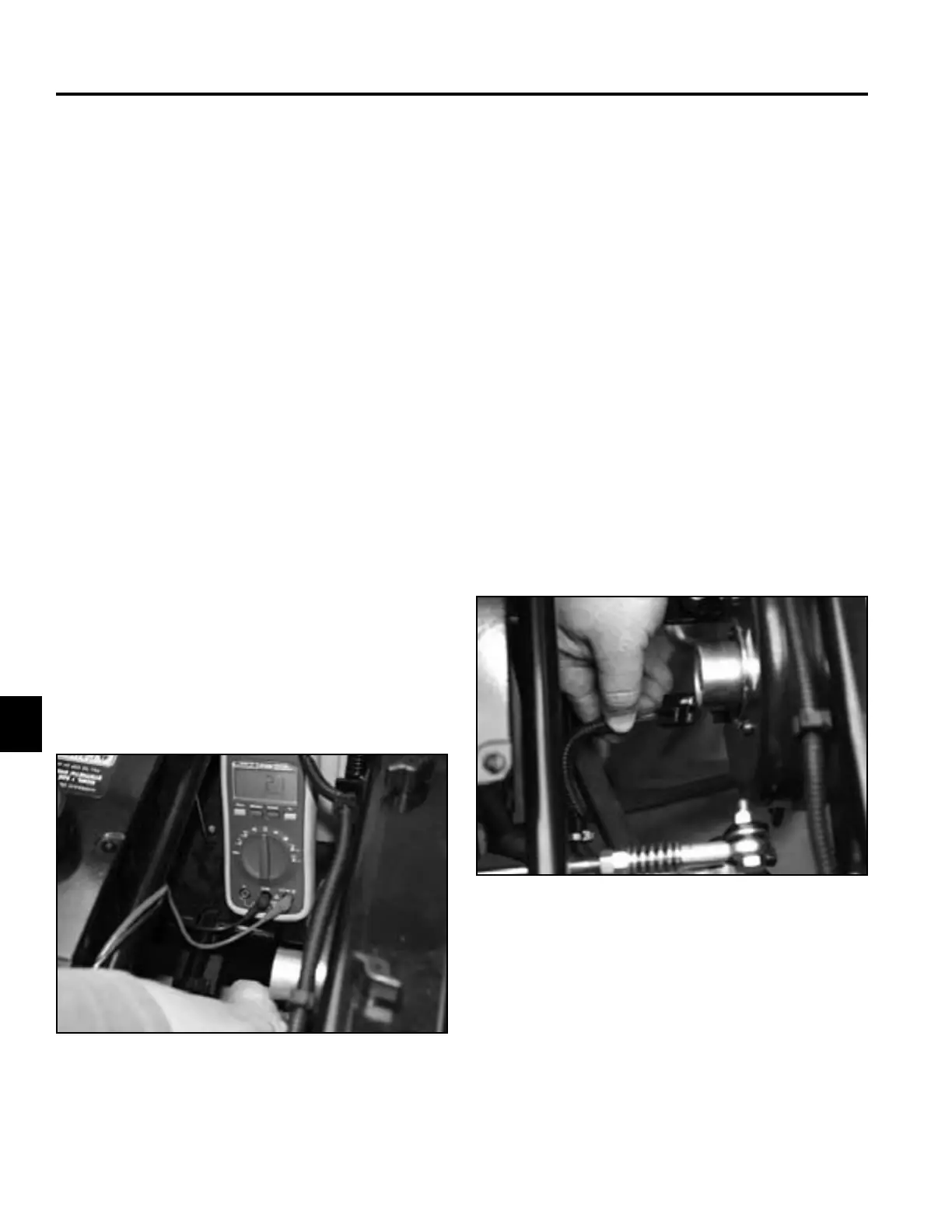

3. Unplug the harness connector from the clutch (Fig.

681).

1. Disengage the PTO, set the parking brake, turn the

ignition to the “off” position and remove the ignition

key. Disconnect negative battery cable.

2. Disconnect the clutch harness from the main

harness.

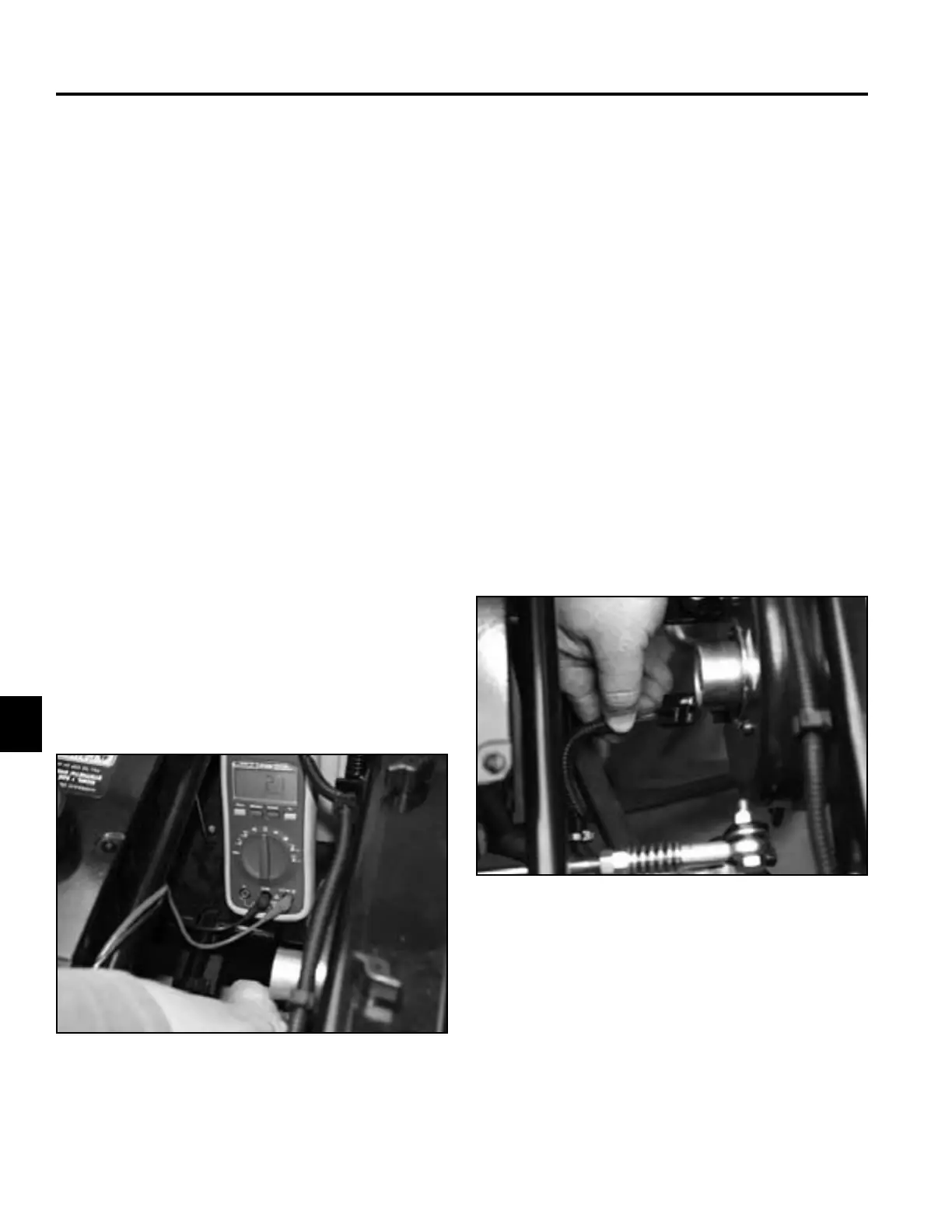

3. Set the multimeter or volt/ohm meter to check

resistance (ohms).

4. Connect the meter lead wires to the clutch wires as

shown (Fig. 680).

Fig 681 PICT-3933

Fig 680 IMG_8116

Loading...

Loading...