Application macros 115

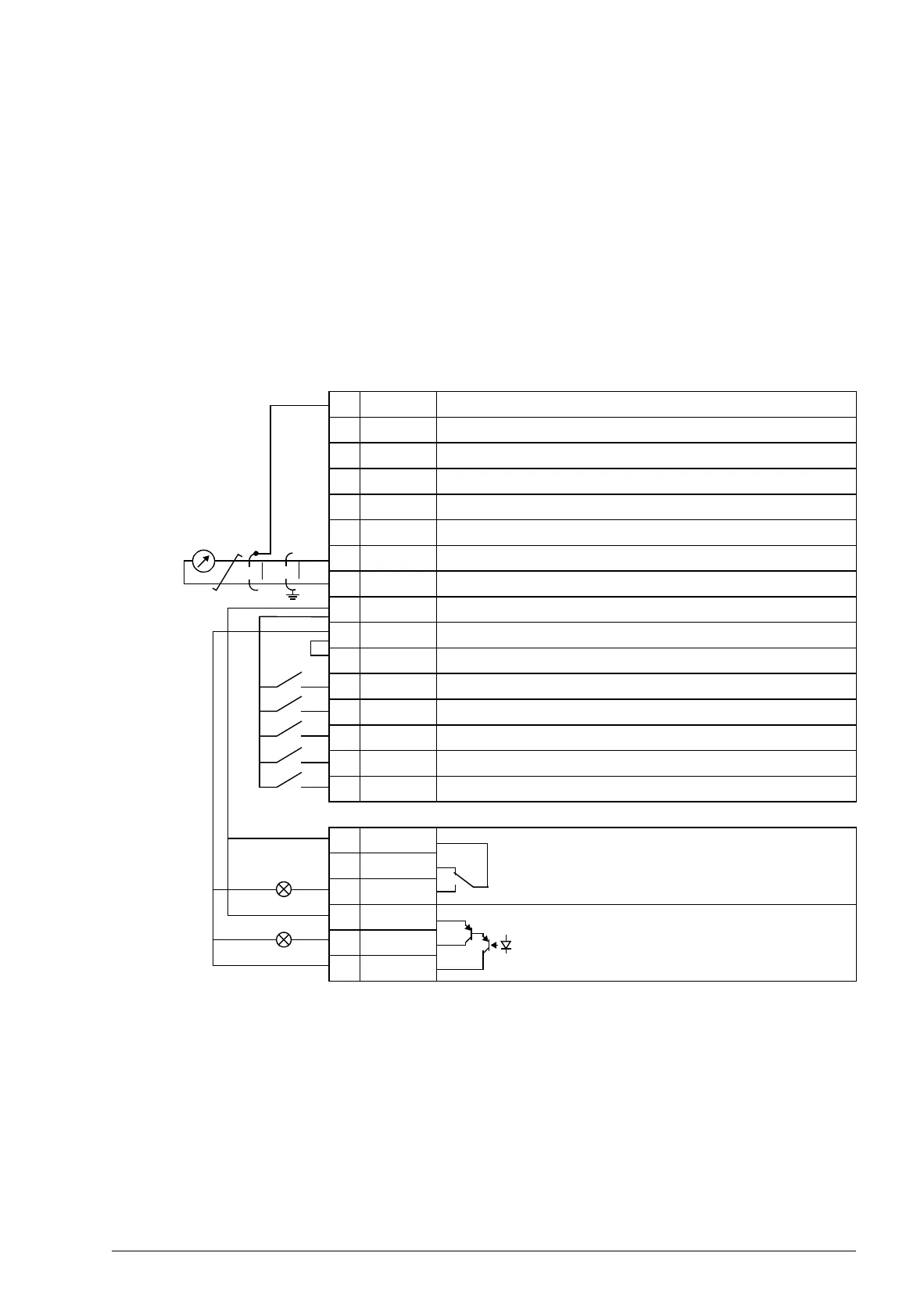

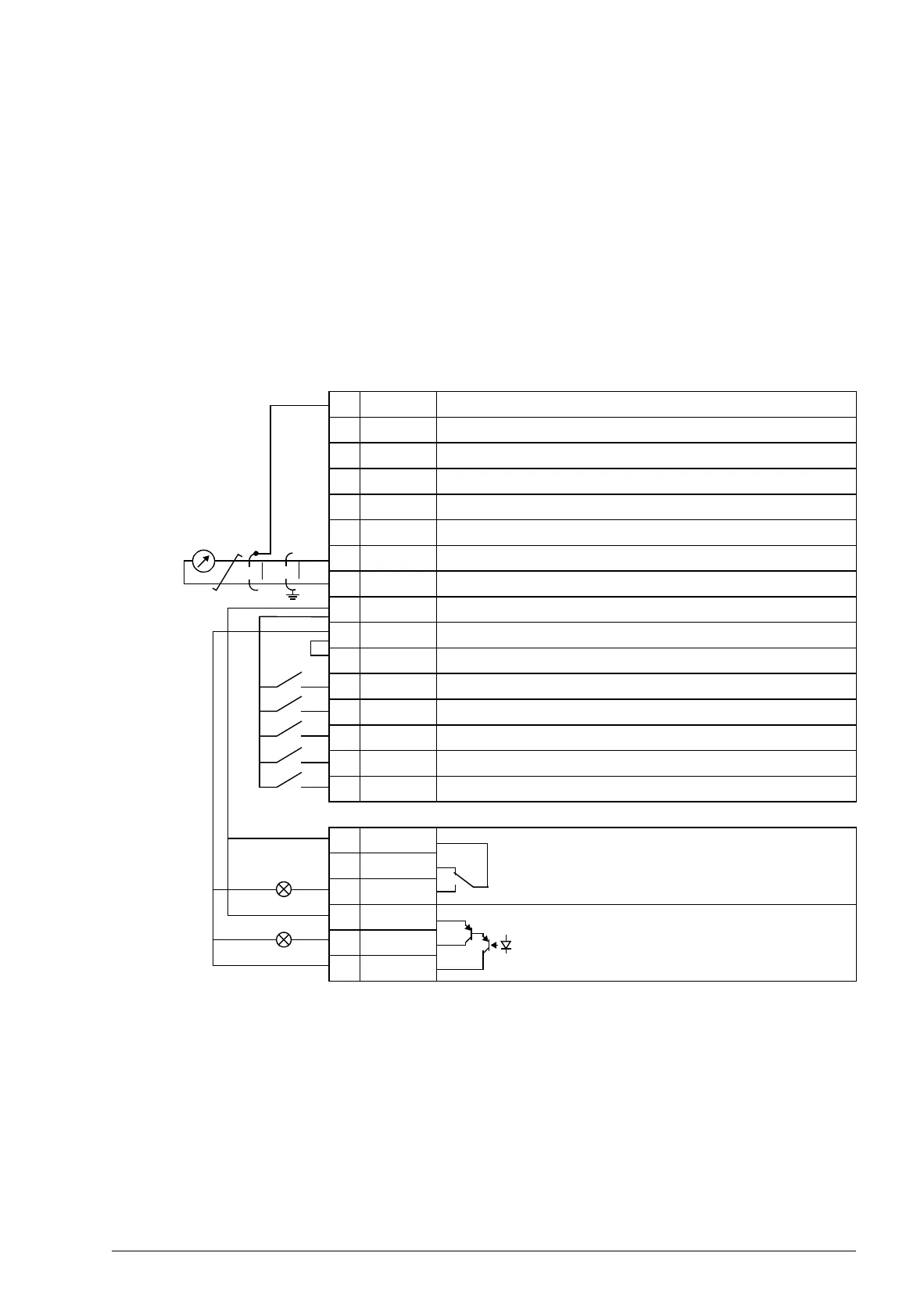

Motor potentiometer macro

This macro provides a cost-effective interface for PLCs that vary the speed of the

motor using only digital signals. To enable the macro, set the value of parameter 9902

APPLIC MACRO to 4 (MOTOR POT).

For the parameter default values, see section Default values with different macros on

page 176. If you use other than the default connections presented below, see section

I/O terminals on page 51.

Default I/O connections

X1A

1 SCR Signal cable shield (screen)

2 AI1 Not in use by default. 0…10 V

3 GND Analog input circuit common

4 +10V Reference voltage: +10 V DC, max. 10 mA

5 AI2 Not in use by default. 0…10 V

6 GND Analog input circuit common

7AO Motor speed value: 0…20 mA

8 GND Analog output circuit common

9 +24V Auxiliary voltage output: +24 V DC, max. 200 mA

10 GND Auxiliary voltage output common

11 DCOM Digital input common

12 DI1 Stop (0) / Start (1)

13 DI2 Forward (0) / Reverse (1)

14 DI3 Speed reference up

1)

15 DI4 Speed reference down

1)

16 DI5 Constant speed 1: parameter 1202

X1B

17 ROCOM Relay output 1

No fault [Fault (-1)]

18 RONC

19 RONO

20 DOSRC Digital output, max. 100 mA

No fault [Fault (-1)]

21 DOOUT

22 DOGND

max. 500 ohm

2)

1)

If DI3 and DI4 are both active or inactive, the

speed reference is unchanged.

The existing speed reference is stored

during stop and power down.

2)

360 degree grounding under a clamp.

Tightening torque = 0.4 N·m / 3.5 lbf·in.

Safe torque off connections (X1C:STO; not

shown in the diagram) are jumpered by default.

Loading...

Loading...