Program features 131

Diagnostics

Programmable analog output

One programmable current output (0…20 mA) is available. Analog output signal can

be inverted, filtered and the maximum and minimum values can be adjusted. The

analog output signals can be proportional to motor speed, output frequency, output

current, motor torque, motor power, etc. The update cycle for the analog output is

2ms.

Analog output can be controlled with Sequence programming. It is also possible to

write a value to an analog output through a serial communication link.

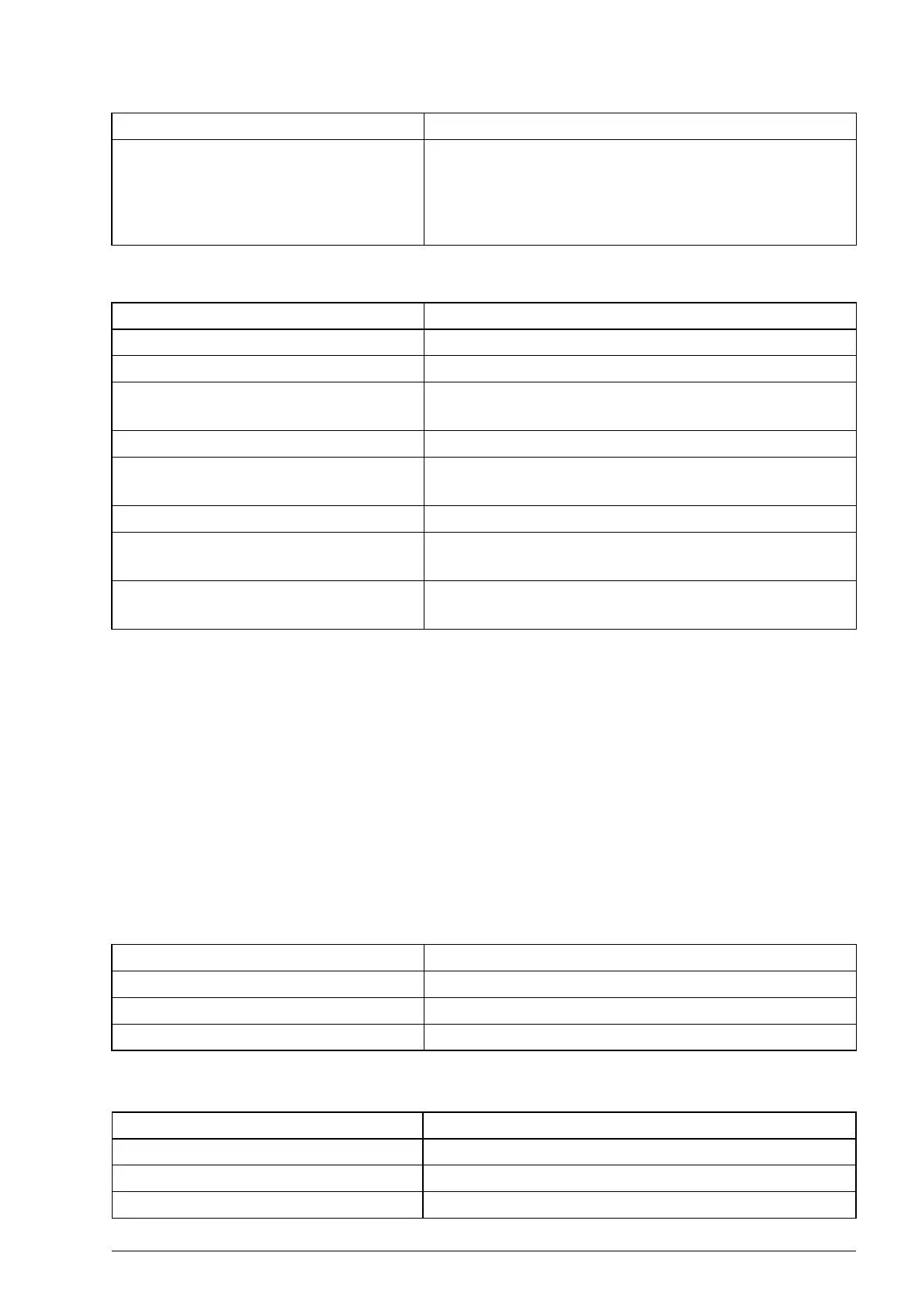

Settings

Diagnostics

8420, 8425, 8426

8430, 8435, 8436

…

8490, 8495, 8496

AI as Sequence programming reference or trigger

signal

Actual signal Additional information

0120, 0121 Analog input values

1401 AI1/A2 signal loss through RO 1

1402/1403/1410 AI1/A2 signal loss through RO 2…4. With option

MREL-01 only.

Alarm

AI1 LOSS / AI2 LOSS AI1/AI2 signal below limit 3021 AI1 FAULT LIMIT /

3022 AI2 FAULT LIMIT

Fault

AI1 LOSS / AI2 LOSS AI1/AI2 signal below limit 3021 AI1 FAULT LIMIT /

3022 AI2 FAULT LIMIT

PAR AI SCALE Incorrect AI signal scaling (1302 < 1301 or 1305 <

1304)

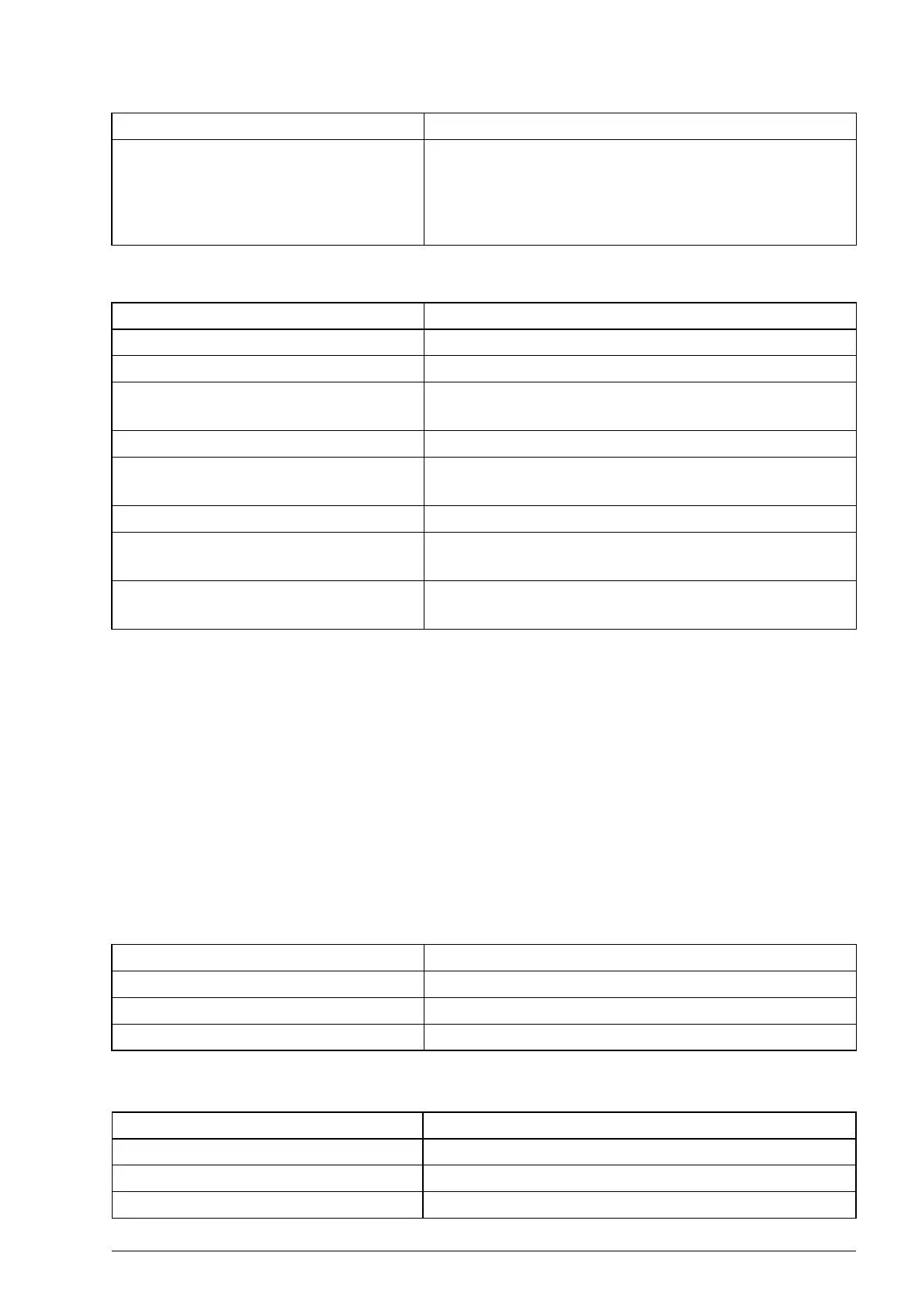

Parameter Additional information

Group 15 ANALOG OUTPUTS AO value selection and processing

Group 35 MOTOR TEMP MEAS AO in motor temperature measurement

8423/8433/…/8493 AO control with Sequence programming

Actual signal Additional information

0124 AO value

0170 AO control values defined by Sequence programming

Fault

Parameter Additional information

Loading...

Loading...