Appendix: Safe torque off (STO) 403

24 V auxiliary voltage load (I/O, panel load, used fieldbus or STO circuits; max.

200 mA) of the drive supplying the STO circuit (see section Control connection data

on page 369). When using external supply, all analog grounds (AGND) of the drives

must be chained together.

Note: Daisy chaining lowers the total system safety integrity level, which needs to be

calculated case by case for each system.

Start-up and commissioning

Always test the operation and reaction of the STO function before commissioning.

Technical data

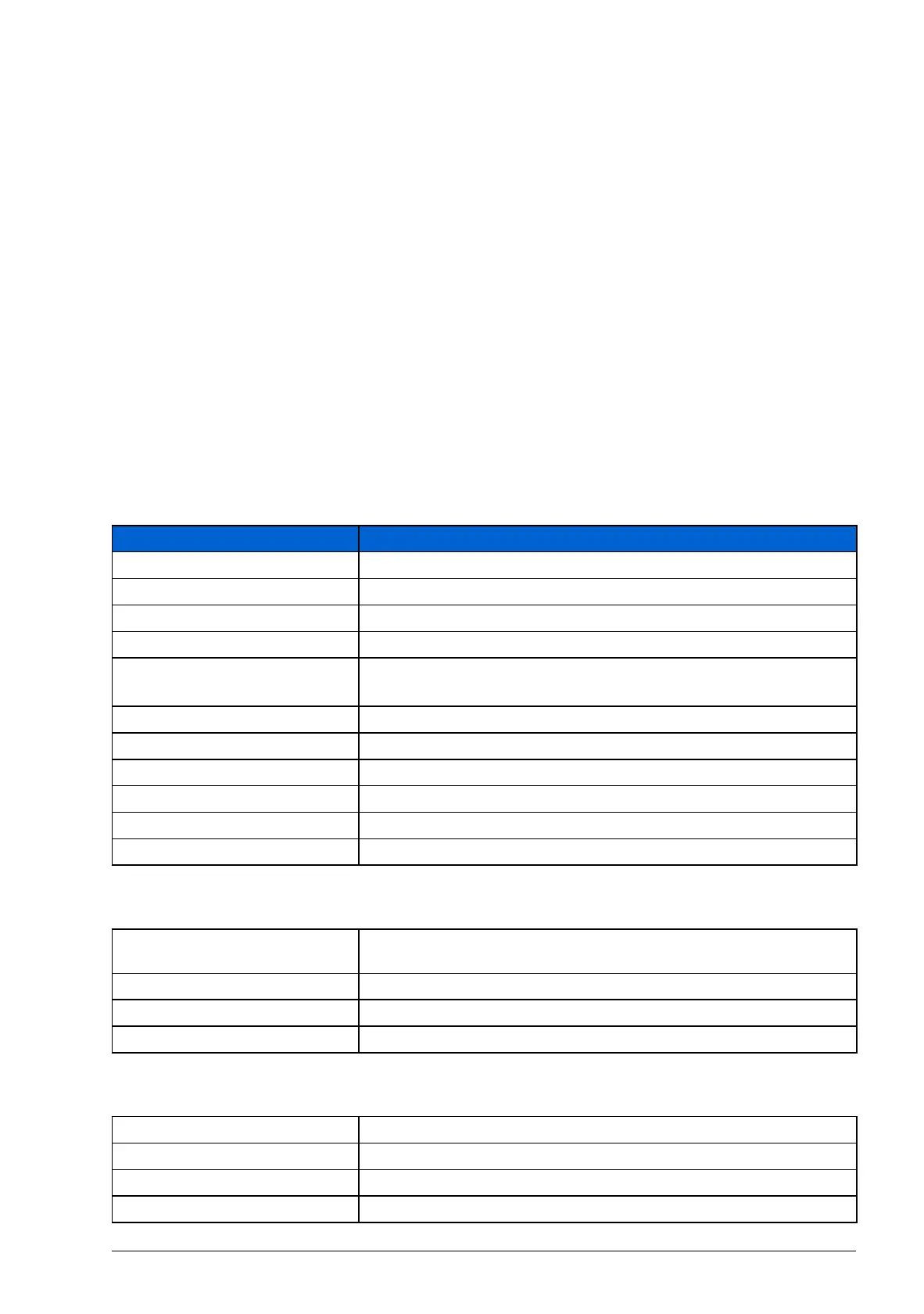

STO components

STO safety relay type

STO connection

STO cable

General requirements IEC 61508 and/or EN/ISO 13849-1

Output requirements

No. of current paths 2 independent paths (one for each STO path)

Switching voltage capability 30 V DC per contact

Switching current capability 100 mA per contact

Maximum switching delay

between contacts

200 ms

Example 1 Simple SIL3 approved safety relay

Type and manufacturer PSR-SCP- 24UC/ESP4/2X1/1X2 by Phoenix Contacts

Approvals EN 954-1, cat 4; IEC 61508, SIL3

Example 2 Programmable safety logic

Type and manufacturer PNOZ Multi M1p by Pilz

Approvals EN 954-1, cat 4; IEC 61508, SIL3; and ISO 13849-1, PL e

Input for external STO

supply

24 V DC ± 10%, load 25 mA

Input impedance R

in

= 2 kohm

Load 12 mA / channel

Output Maximum load 200 mA depending on I/O load

Type 2×2 cables, low voltage, single shielded, twisted pair cable

Conductor size 1.5…0.25 mm

2

(16…24 AWG)

Maximum length Max. 25 m between STO inputs and the operating contact

Tightening torque 0.5 N·m (4.4 lbf·in)

Loading...

Loading...