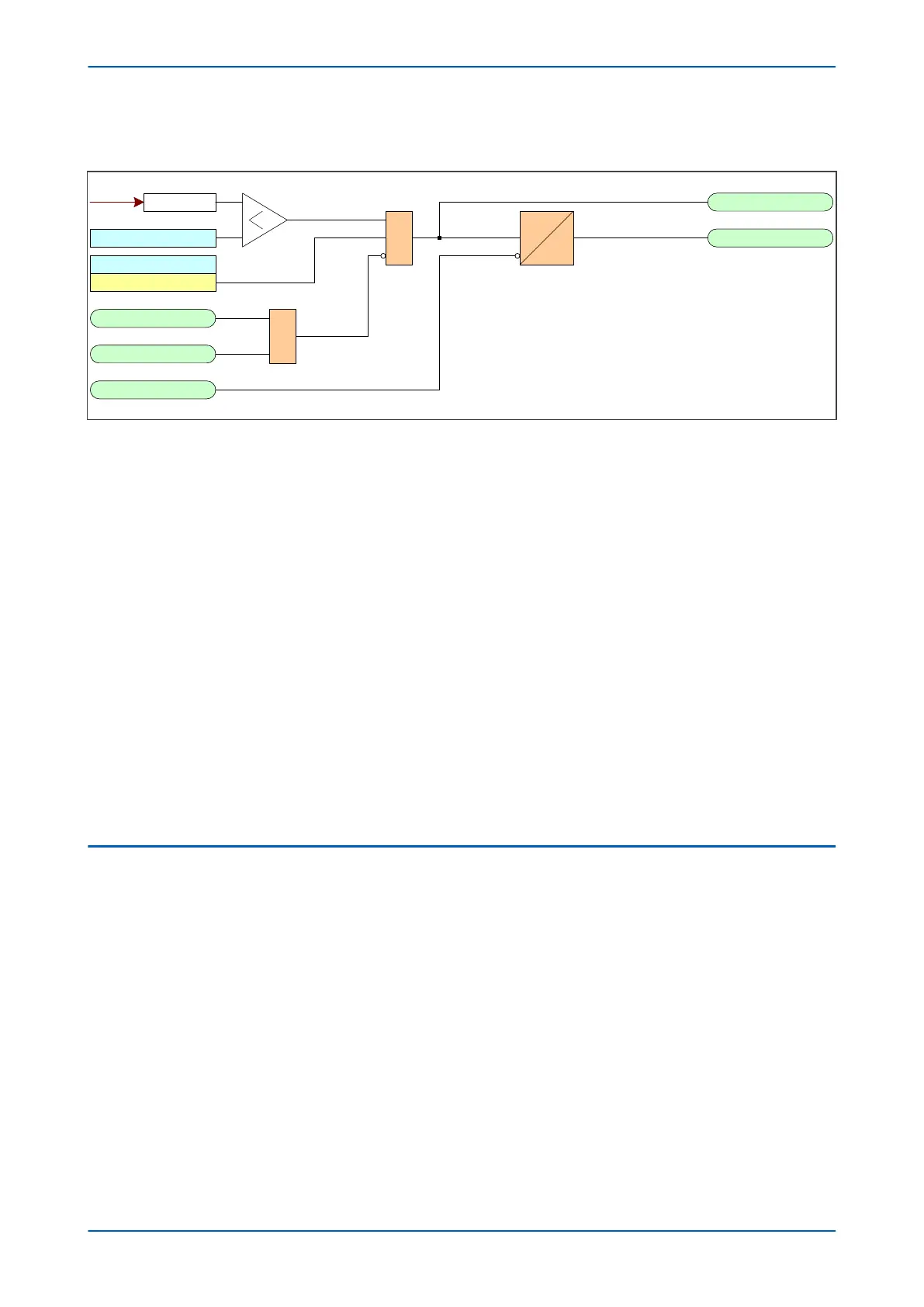

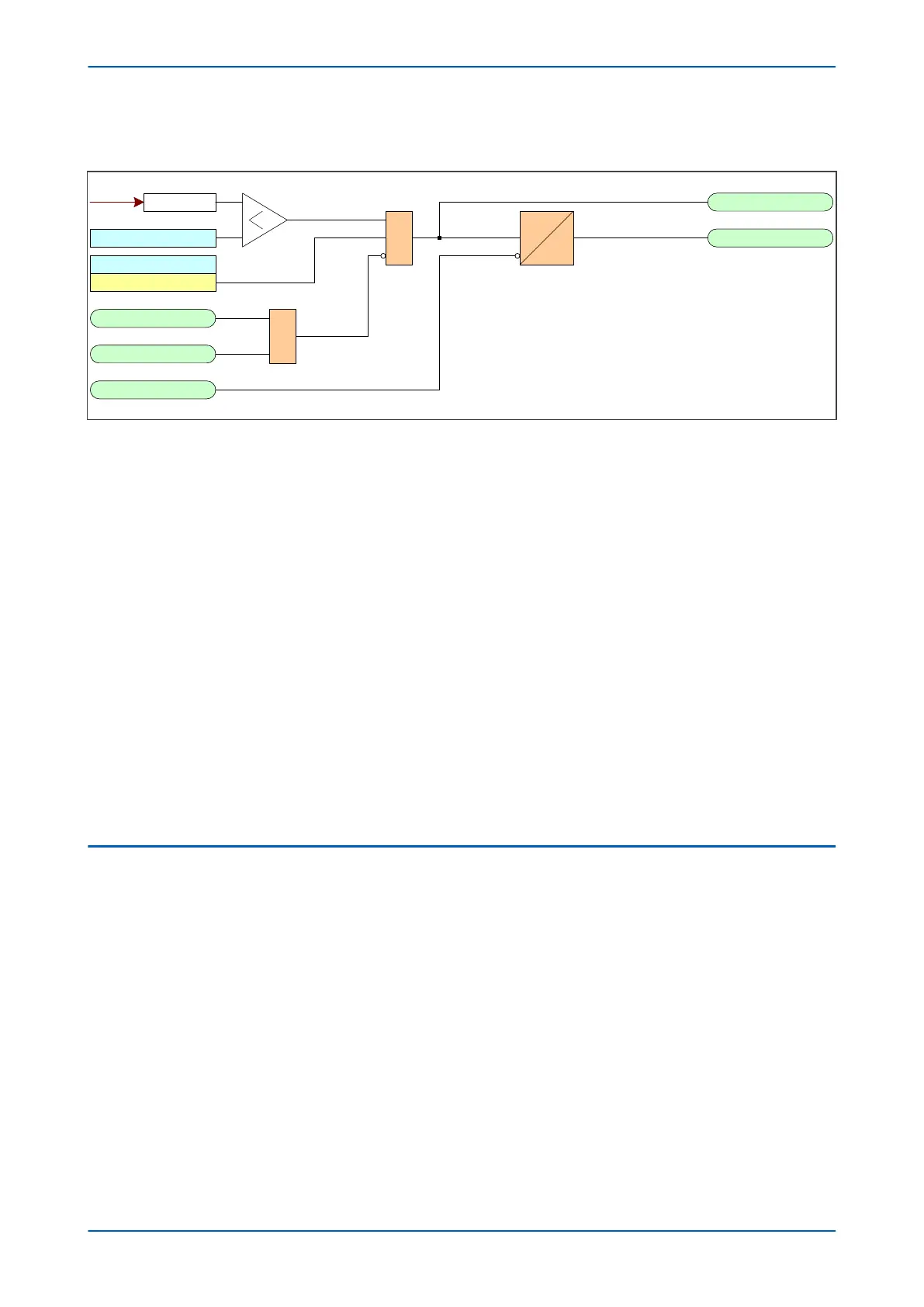

2.1.2 UNDERFREQUENCY PROTECTION LOGIC

F<1 TripF<1 Trip

F<1 StatusF<1 Status

V00861

FreqFreq

DT

F<1 StartF<1 Start

&

EnabledEnabled

F<1 SettingF<1 Setting

Freq Not FoundFreq Not Found

AveragingAveraging

F<1 Timer BlockF<1 Timer Block

All Poles DeadAll Poles Dead

1

890

1370

1149

1155

1161

Figure 237: Underfrequency logic (single stage)

If the frequency is below the setting and not blocked the DT timer is started. If the frequency cannot be

determined, the function is blocked.

2.1.3

APPLICATION NOTES

2.1.3.1 SETTING GUIDELINES

In order to minimise the effects of underfrequency, a multi-stage load shedding scheme may be used with the

plant loads prioritised and grouped. During an underfrequency condition, the load groups are disconnected

sequentially, with the highest priority group being the last one to be disconnected.

The effectiveness of each load shedding stage depends on the proportion of power deficiency it represents. If the

load shedding stage is too small compared with the prevailing generation deficiency, then there may be no

improvement in the frequency. This should be taken into account when forming the load groups.

Time delays should be sufficient to override any transient dips in frequency, as well as to provide time for the

frequency controls in the system to respond. These should not be excessive as this could jeopardize system

stability. Time delay settings of 5 - 20 s are typical.

The protection function should be set so that declared frequency-time limits for the generating set are not

infringed. Typically, a 10% underfrequency condition should be continuously sustainable.

2.2

OVERFREQUENCY PROTECTION

An increased system frequency arises when the mechanical power input to a generator exceeds the electrical

power output. This could happen, for instance, when there is a sudden loss of load due to tripping of an outgoing

feeder from the plant to a load centre. Under such conditions, the governor would normally respond quickly to

obtain a balance between the mechanical input and electrical output, thereby restoring normal frequency.

Overfrequency protection is required as a backup to cater for cases where the reaction of the control equipment is

too slow.

2.2.1

OVERFREQUENCY PROTECTION IMPLEMENTATION

Simple overfrequency Protection is configured in the FREQ PROTECTION column of the relevant settings group.

The device provides 2 stages of overfrequency protection. The function uses the following settings (shown for

stage 1 only - other stages follow the same principles).

● F>1 Status: enables or disables underfrequency protection for the relevant stage

● F>1 Setting: defines the frequency pickup setting

● F>1 Time Delay: sets the time delay

P543i/P545i Chapter 15 - Frequency Protection Functions

P54x1i-TM-EN-1 413

Loading...

Loading...