COOLING SYSTEM

RADIATOR CAP/SYSTEM PRESSURE

INSPECTION

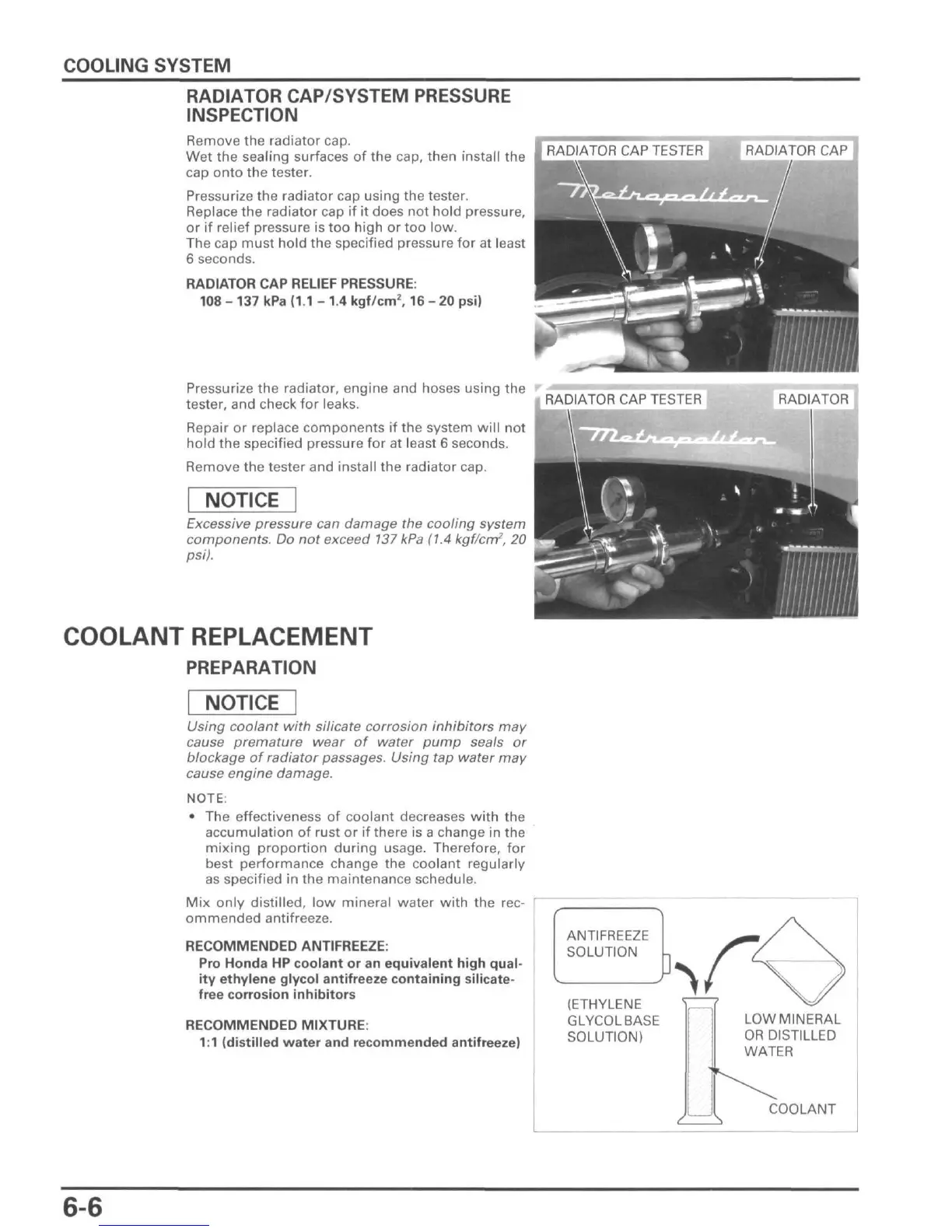

Remove the radiator cap.

Wet the sealing surfaces of the cap, then install the

cap onto the tester.

Pressurize the radiator cap using the tester.

Replace the radiator cap if it does not hold pressure,

or if relief pressure is too high or too low.

The cap must hold the specified pressure for at least

6 seconds.

RADIATOR CAP RELIEF PRESSURE:

108 - 137 kPa (1.1 - 1.4 kgf/cm

2

,16 - 20 psi)

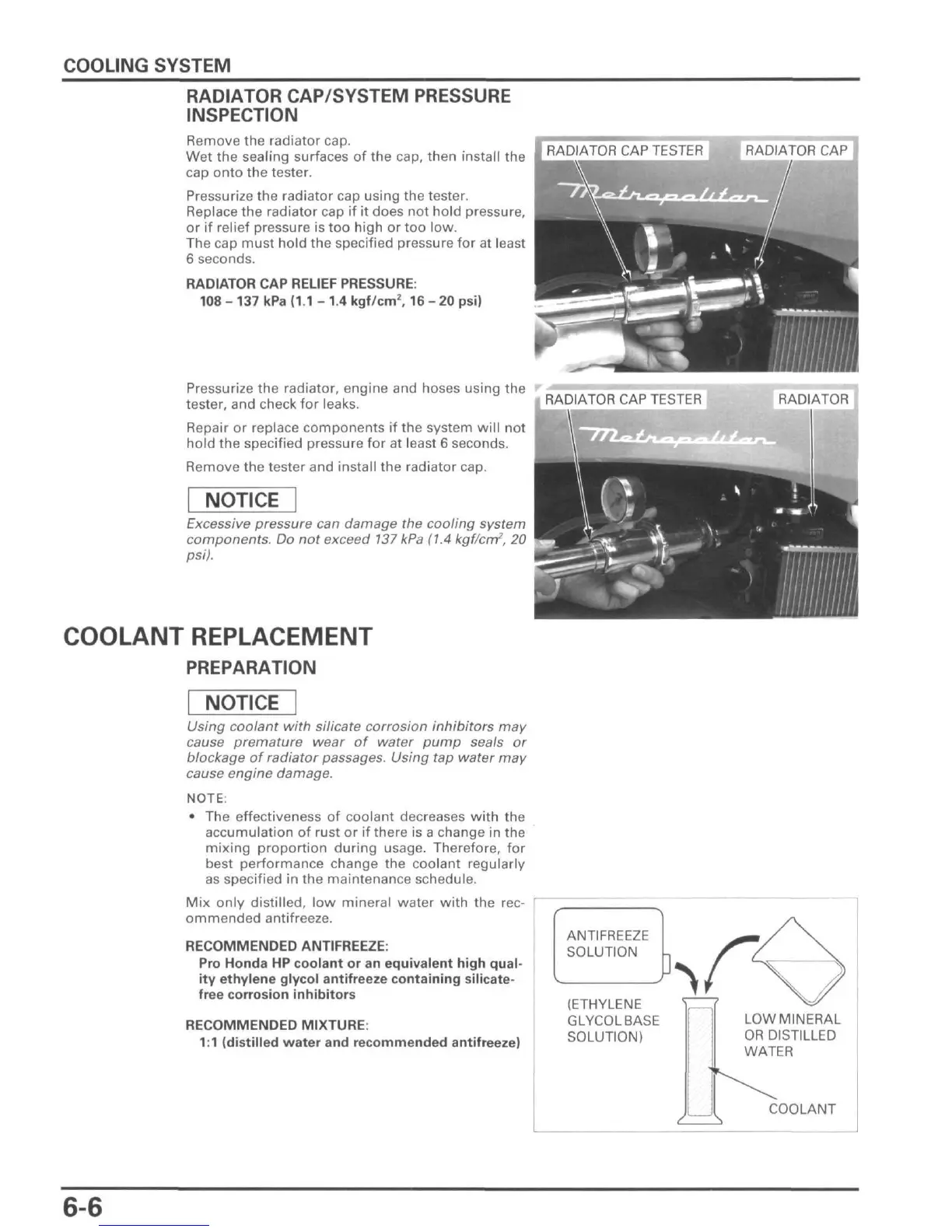

Pressurize the radiator, engine and hoses using the

tester, and check for leaks.

Repair or replace components if the system will not

hold the specified pressure for at least 6 seconds.

Remove the tester and install the radiator cap.

NOTICE

Excessive

pressure can damage the cooling system

components. Do not exceed

137 kPa

(1.4 kgf/cm

2

, 20

psi).

RADIATOR CAP TESTER

RADIATOR CAP TESTER

COOLANT REPLACEMENT

PREPARATION

NOTICE

Using coolant with silicate corrosion inhibitors may

cause premature wear of water pump seals or

blockage of radiator

passages.

Using tap water may

cause engine damage.

NOTE:

• The effectiveness of coolant decreases with the

accumulation of rust or if there is a change in the

mixing proportion during usage. Therefore, for

best performance change the coolant regularly

as specified in the maintenance schedule.

Mix only distilled, low mineral water with the rec-

ommended antifreeze.

RECOMMENDED ANTIFREEZE:

Pro Honda HP coolant or an equivalent high qual-

ity ethylene glycol antifreeze containing silicate-

free corrosion inhibitors

RECOMMENDED MIXTURE:

1:1 (distilled water and recommended antifreeze)

ANTIFREEZE

SOLUTION

(ETHYLENE

GLYCOL BASE

SOLUTION)

LOW MINERAL

OR DISTILLED

WATER

COOLANT

6-6

Loading...

Loading...