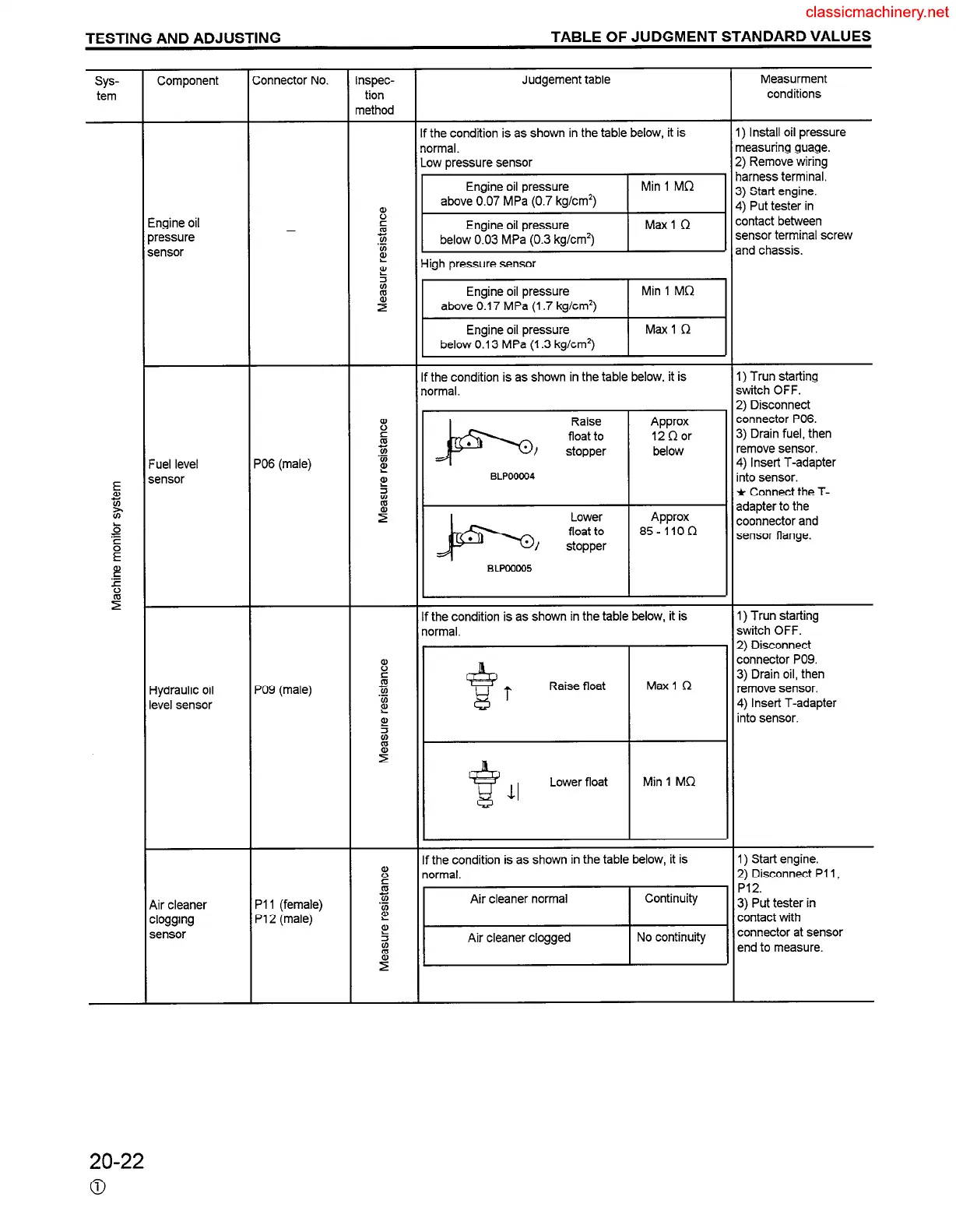

TESTING AND ADJUSTING

TABLE OF JUDGMENT STANDARD VALUES

sys-

tem

Component

Engine oil

xessure

sensor

Fuel level

sensor

Hydraulic oil

level sensor

Air cleaner

clogging

sensor

ionnector No.

_

‘06 (male)

‘09 (male)

VI (female)

‘12 (male)

nspec-

tion

nethod

Judgement table

f the condition is as shown in the table below, it is

iormal.

Low pressure sensor

11

High pressure sensor

If the condition is as shown in the table below, it is

normal.

the condition is as shown in the table below, it is

xmal.

I I

Raisefloat 1 Maxi C? ~ $ r

Lower float Min 1 MD

the condition is as shown in the table below, it is

ormal.

Air cleaner normal

I

Continuity

Air cleaner clogged

No continuity

Measurment

conditions

I) Install oil pressure

neasuring guage.

?) Remove wiring

larness terminal.

3) Start engine.

1) Put tester in

:ontact between

sensor terminal screw

2nd chassis.

I) Trun starting

switch OFF.

2) Disconnect

:onnector P06.

3) Drain fuel, then

‘emove sensor.

1) Insert T-adapter

nto sensor.

k Connect the T-

adapter to the

:oonnector and

sensor flange.

I) Trun starting

switch OFF.

2) Disconnect

:onnector PO9.

3) Drain oil, then

‘emove sensor.

4) Insert T-adapter

nto sensor.

1) Start engine.

2) Disconnect PI 1,

P12.

3) Put tester in

contact with

connector at sensor

end to measure.

20-22

0

Loading...

Loading...