DISASSEMBLY AND ASSEMBLY

TRACK ROLLER

REMOVAL OF TRACK ROLLER

ASSEMBLY

1.

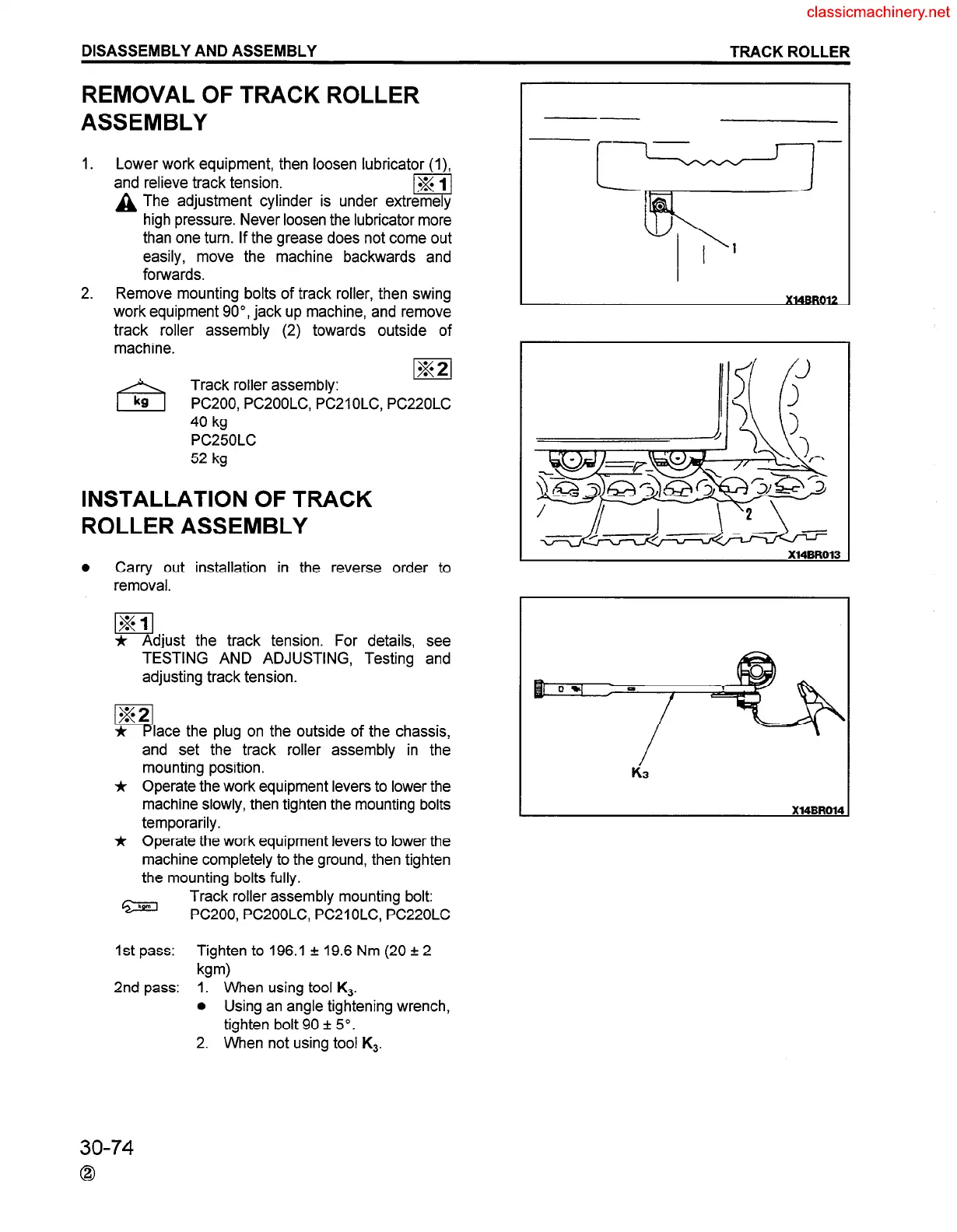

Lower work equipment, then loosen lubricator (1)

and relieve track tension.

m

A The adjustment cylinder is under extremely

high pressure. Never loosen the lubricator more

than one turn. If the grease does not come out

easily, move the machine backwards and

forwards.

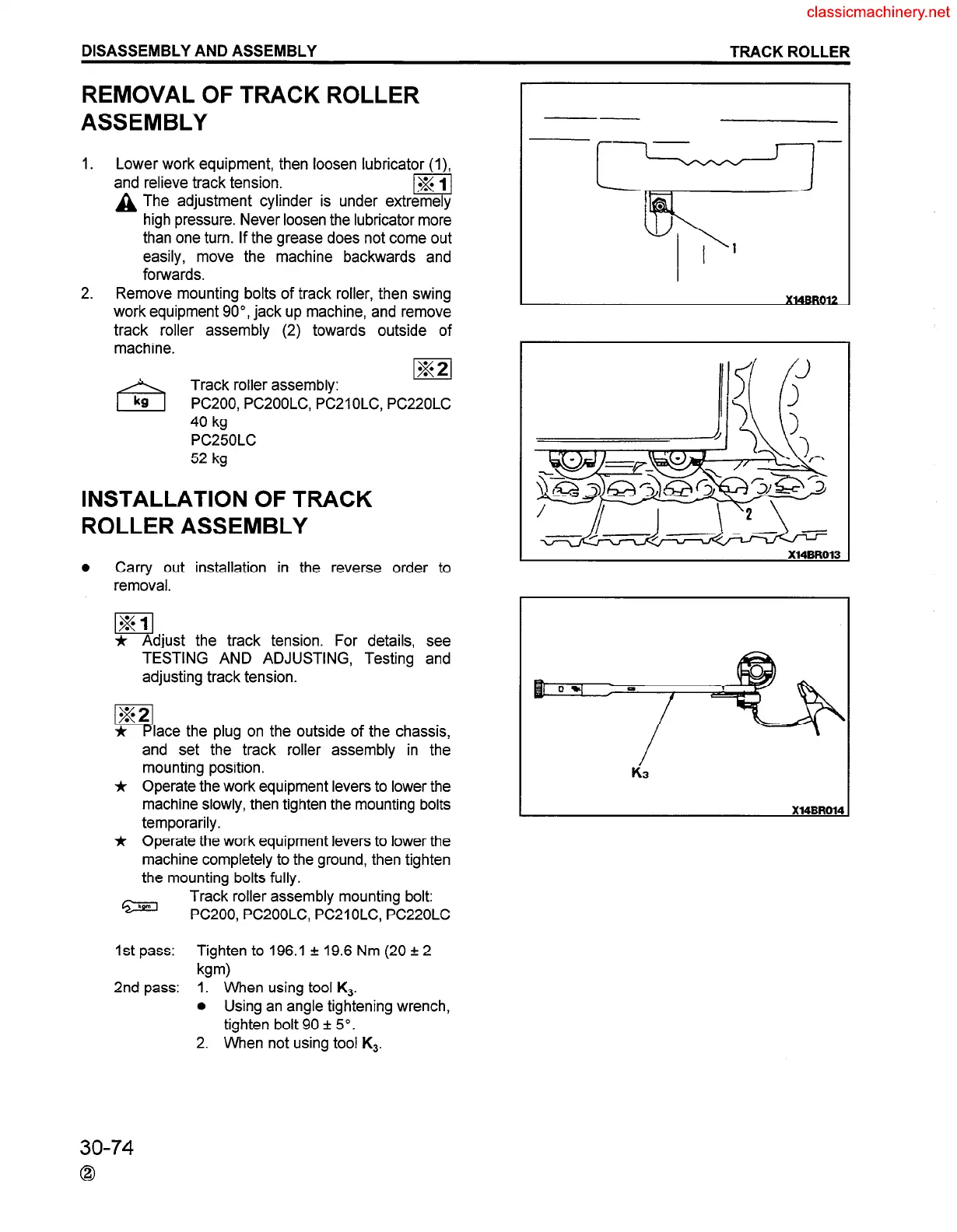

2. Remove mounting bolts of track roller, then swing

work equipment 90”, jack up machine, and remove

track roller assembly (2) towards outside of

machine.

Track roller assembly:

PC200, PC2OOLC, PC21 OLC, PC220LC

40 kg

PC25OLC

52 kg

INSTALLATION OF TRACK

ROLLER ASSEMBLY

l

Carry out installation in the reverse order to

removal.

* Adjust the track tension. For details, see

TESTING AND ADJUSTING, Testing and

adjusting track tension.

lace the plug on the outside of the chassis,

*

*

and set the-track roller assembly in the

mounting position.

Operate the work equipment levers to lower the

machine slowly, then tighten the mounting bolts

temporarily.

Operate the work equipment levers to lower the

machine completely to the ground, then tighten

the mounting bolts fully.

Track roller assembly mounting bolt:

PC200, PC2OOLC, PC21 OLC, PC22OLC

--

i--I-

I

,

K3

1st pass: Tighten to 196.1 + 19.6 Nm (20 + 2

kgm)

2nd pass: 1. When using tool K,.

l Using an angle tightening wrench,

tighten bolt 90 f 5”.

2. When not using tool KJ.

30-74

0

Loading...

Loading...