DISASSEMBLY AND ASSEMBLY

WORK EQUIPMENT

REMOVAL OF WORK

EQUIPMENT ASSEMBLY

A

Extend the arm and bucket fully, lower the work

equipment to the ground, and set the safety lock

lever to the LOCK position.

1.

2.

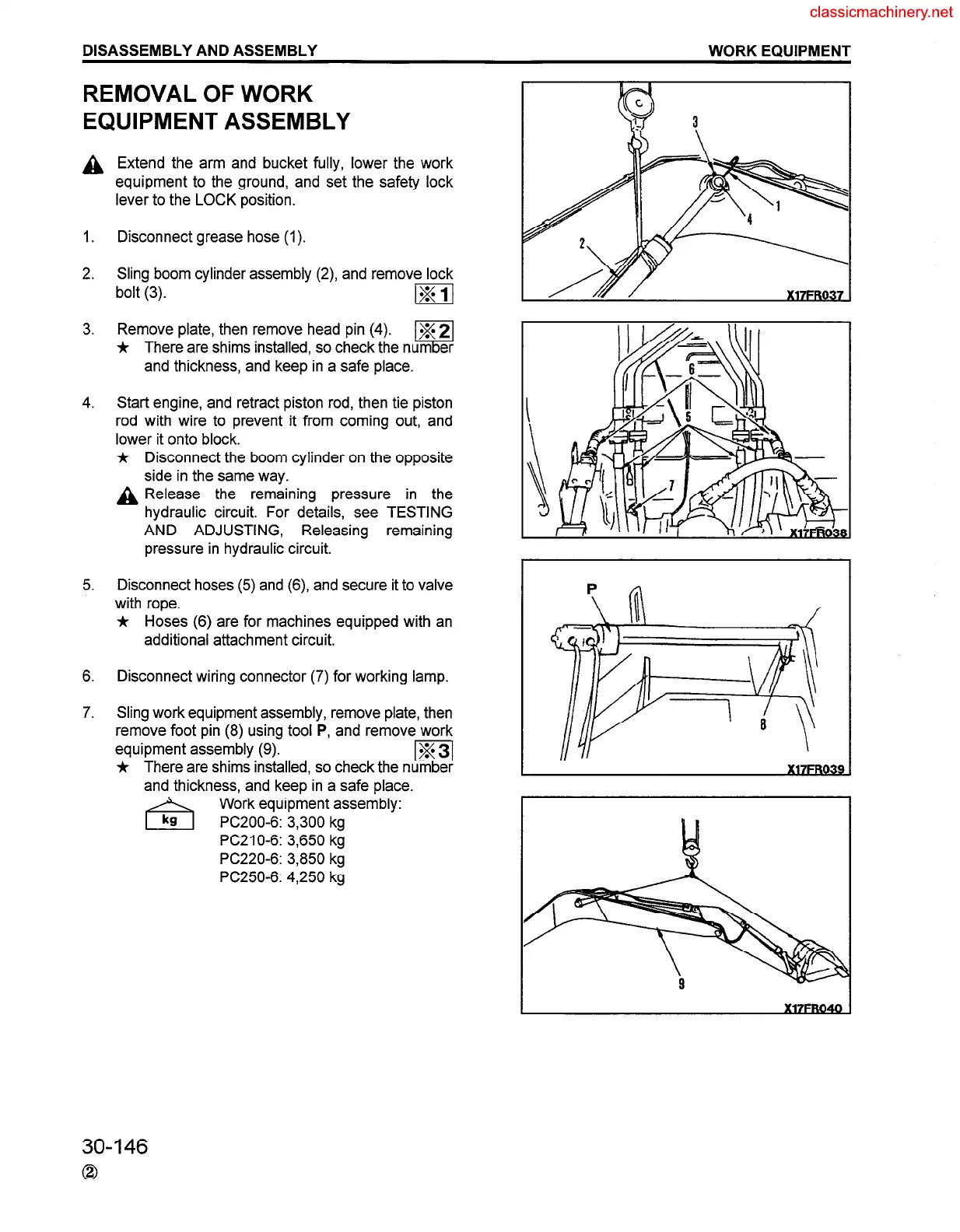

Disconnect grease hose (1).

Sling boom cylinder assembly (2), and remove lock

bolt (3).

mj

3.

Remove plate, then remove head pin (4).

m

* There are shims installed, so check the number

and thickness, and keep in a safe place.

4. Start engine, and retract piston rod, then tie piston

rod with wire to prevent it from coming out, and

lower it onto block.

*

A

Disconnect the boom cylinder on the opposite

side in the same way.

Release the remaining pressure in the

hydraulic circuit. For details, see TESTING

AND ADJUSTING, Releasing remaining

pressure in hydraulic circuit.

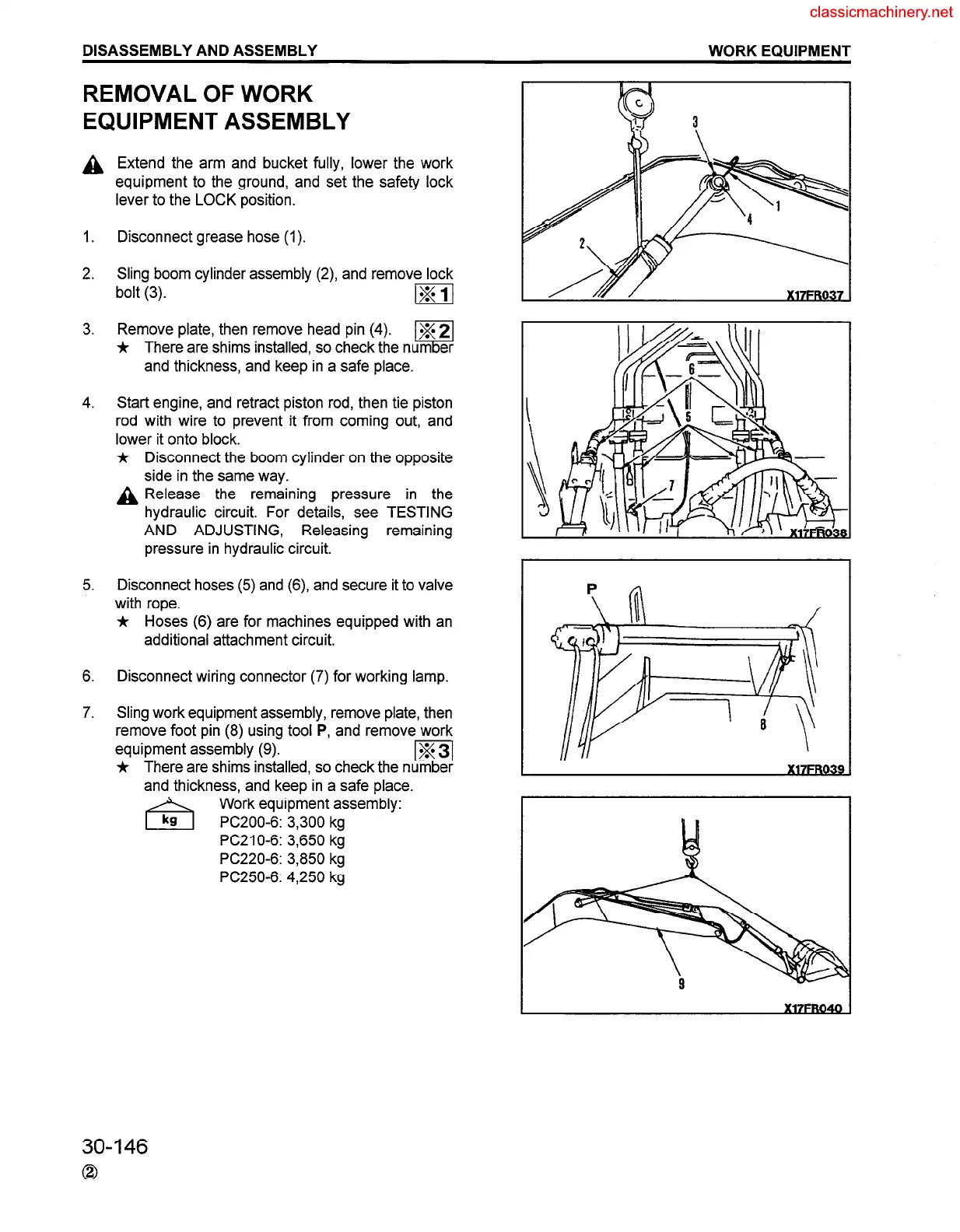

5. Disconnect hoses (5) and (6) and secure it to valve

with rope.

* Hoses (6) are for machines equipped with an

additional attachment circuit.

6.

Disconnect wiring connector (7) for working lamp.

7. Sling work equipment assembly, remove plate, then

remove foot pin (8) using tool P, and remove work

equipment assembly (9).

j, There are shims installed, so check the

and thickness, and keep in a safe place.

Work equipment assembly:

PC200-6: 3,300 kg

PC210-6: 3,650 kg

PC220-6: 3,850 kg

PC250-6: 4,250 kg

30-146

0

Loading...

Loading...