TESTING AND ADJUSTING

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

TESTING LOCATIONS CAUSING

HYDRAULIC DRIFT OF WORK

EQUIPMENT

*

If there is any hydraulic drift in the work equipment

(cylinders), check as follows to determine if the cause

is in the cylinder packing or in the control valve.

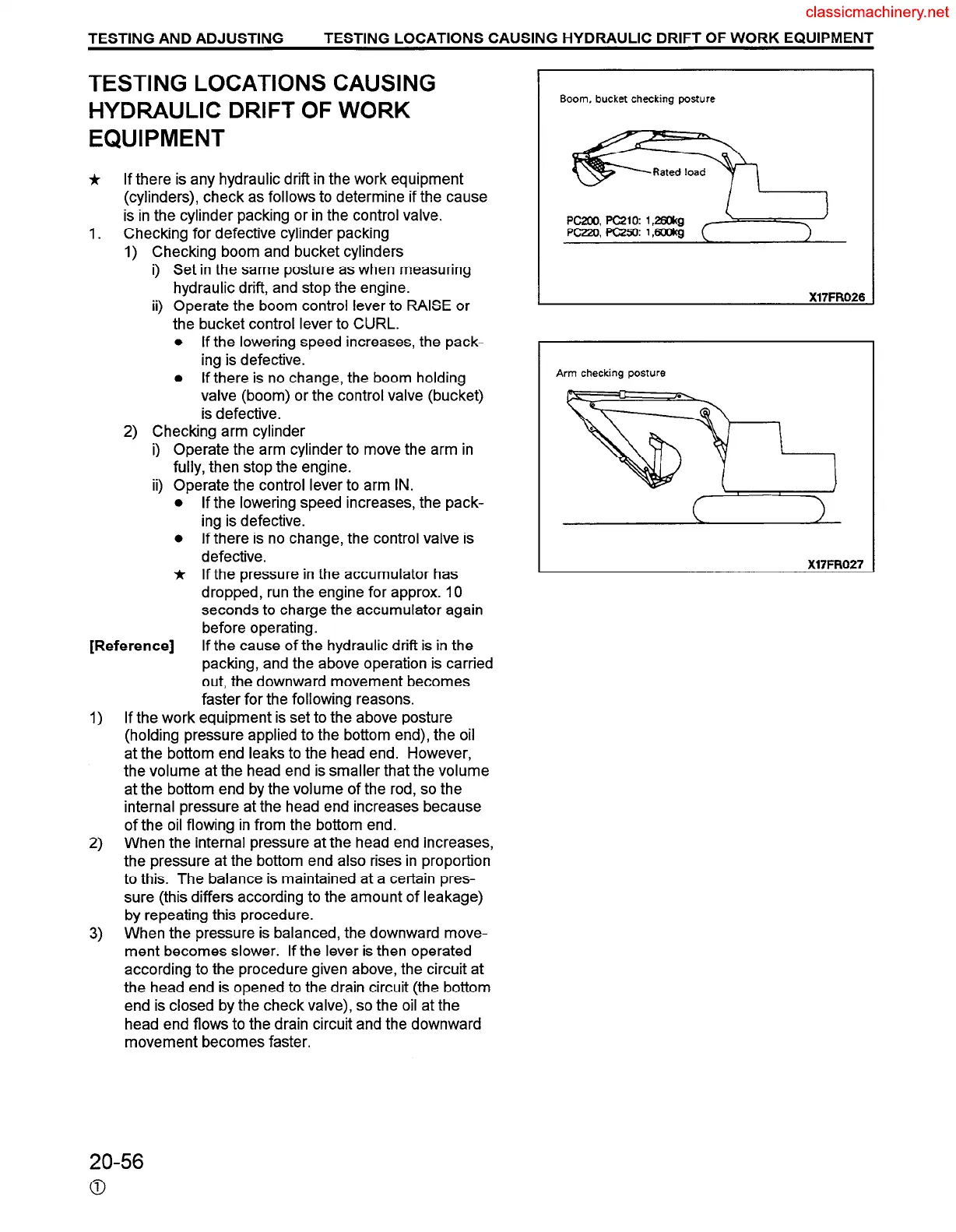

1. Checking for defective cylinder packing

1) Checking boom and bucket cylinders

i) Set in the same posture as when measuring

hydraulic drift, and stop the engine.

ii) Operate the boom control lever to RAISE or

the bucket control lever to CURL.

l If the lowering speed increases, the pack-

ing is defective.

l If there is no change, the boom holding

valve (boom) or the control valve (bucket)

is defective.

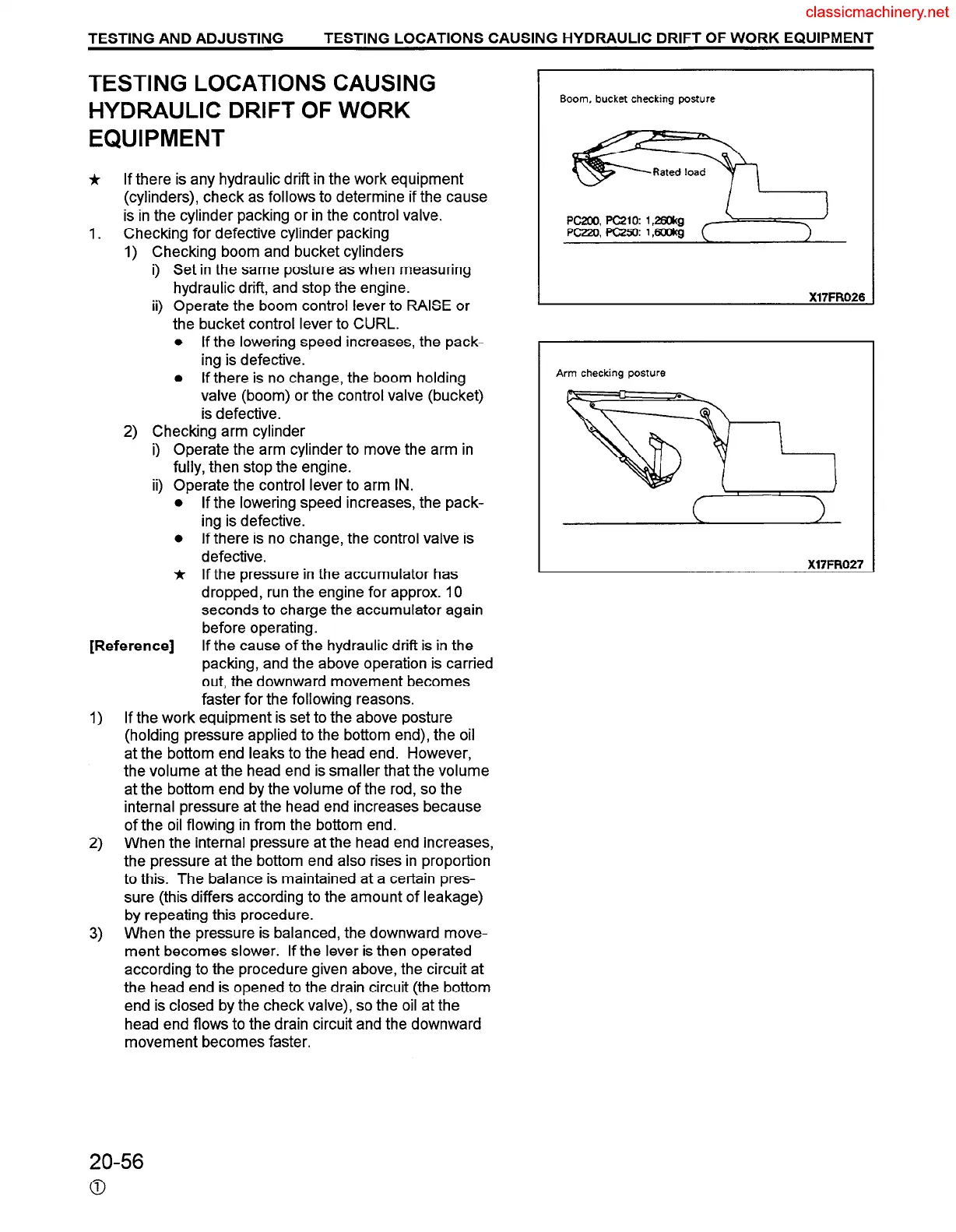

2) Checking arm cylinder

0

ii)

Operate the arm cylinder to move the arm in

fully, then stop the engine.

Operate the control lever to arm IN.

l If the lowering speed increases, the pack-

ing is defective.

l If there is no change, the control valve is

defective.

* If the pressure in the accumulator has

dropped, run the engine for approx. IO

seconds to charge the accumulator again

before operating.

[Reference]

If the cause of the hydraulic drift is in the

packing, and the above operation is carried

out, the downward movement becomes

faster for the following reasons.

1) If the work equipment is set to the above posture

(holding pressure applied to the bottom end), the oil

at the bottom end leaks to the head end. However,

the volume at the head end is smaller that the volume

at the bottom end by the volume of the rod, so the

internal pressure at the head end increases because

of the oil flowing in from the bottom end.

2) When the internal pressure at the head end increases,

the pressure at the bottom end also rises in proportion

to this. The balance is maintained at a certain pres-

sure (this differs according to the amount of leakage)

by repeating this procedure.

3) When the pressure is balanced, the downward move-

ment becomes slower. If the lever is then operated

according to the procedure given above, the circuit at

the head end is opened to the drain circuit (the bottom

end is closed by the check valve), so the oil at the

head end flows to the drain circuit and the downward

movement becomes faster.

Boom, bucket checking posture

Y1?FRO26

Arm checking posture

20-56

a

Loading...

Loading...