TESTING AND ADJUSTING

BLEEDING AIR

BLEEDING AIR

Order of operations and procedure for bleeding air (Note 2)

Air bleeding item

1

Air bleeding procedure

Nature of work

l Replace hydraulic oil

0 Clean strainer

l Replace return filter element

l Replace, repair pump

l Remove suction piping

l Replace, repair control valve

l Replace cylinder

l Remove cylinder piping

l Replace swing motor

l Replace swing motor piping

l Replace travel motorswivel

l Remove travel motorswivel

piping

0

0 0

l Replace EPC valve

0

0

Note 1: Bleed air from the swing and travel motors only when the oil inside the motor case had been drained.

0 0

0

Note 2: Perform only those procedures marked with a 0 for each tvoe of work.

I. Bleeding air from pump

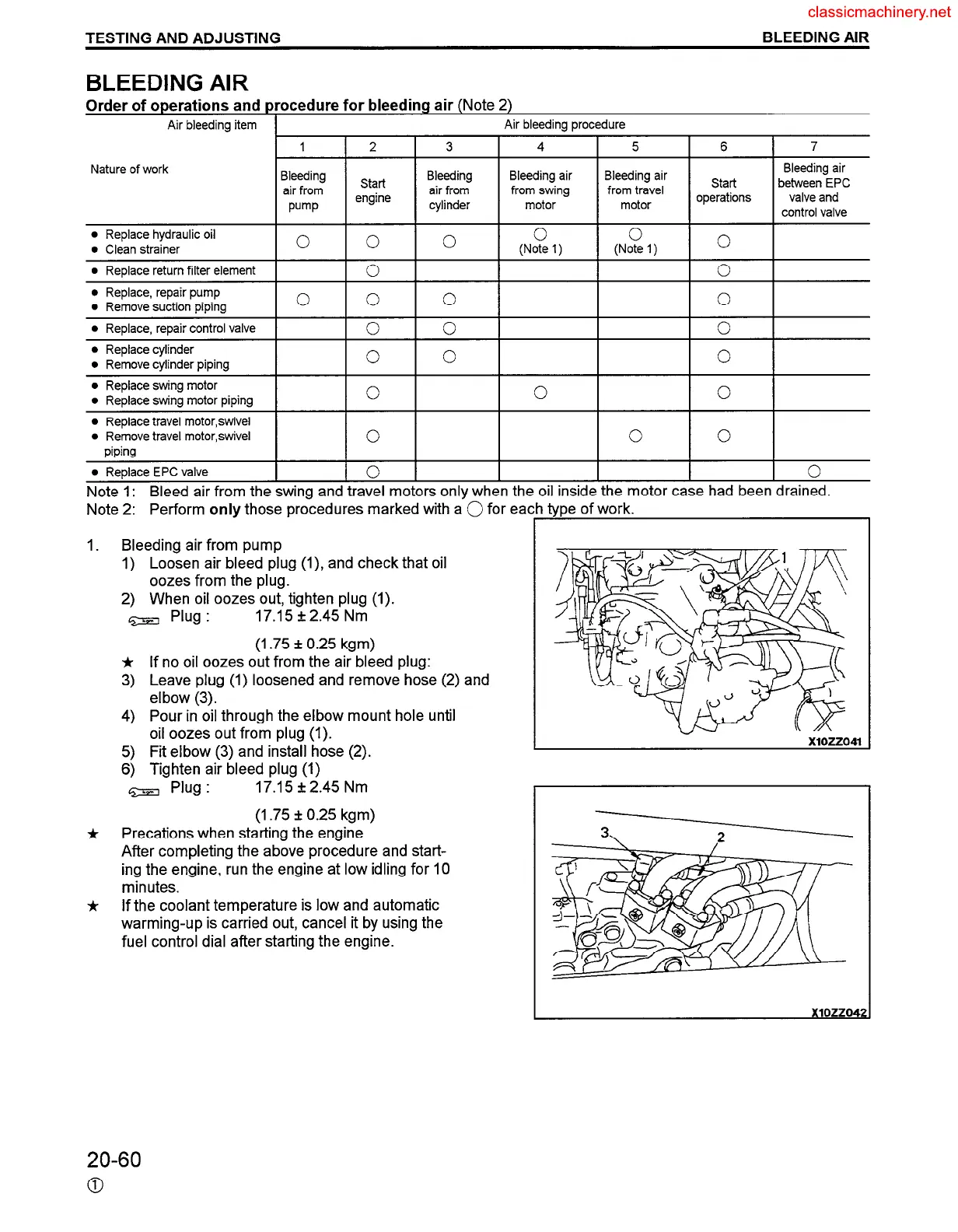

1) Loosen air bleed plug (I), and check that oil

oozes from the plug.

2) When oil oozes out, tighten plug (1).

- Plug :

17.15 +2.45 Nm

(1.75 f 0.25 kgm)

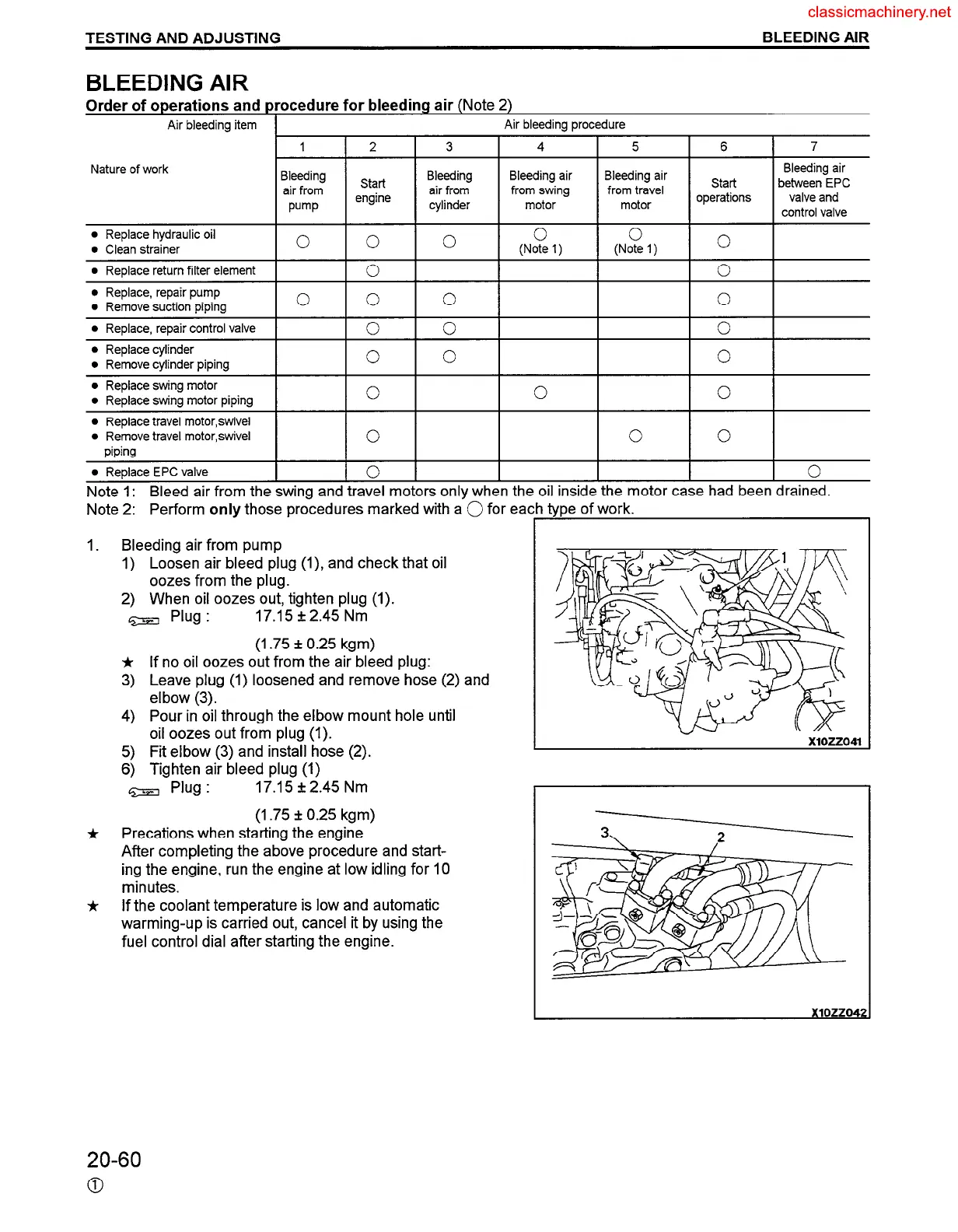

$r If no oil oozes out from the air bleed plug:

3) Leave plug (1) loosened and remove hose (2) and

elbow (3).

4) Pour in oil through the elbow mount hole until

oil oozes out from plug (1).

5) Fit elbow (3) and install hose (2).

6) Tighten air bleed plug (1)

- Plug : 17.15 1t2.45 Nm

(1.75 f 0.25 kgm)

*

Precations when starting the engine

After completing the above procedure and start-

ing the engine, run the engine at low idling for 10

minutes.

*

If the coolant temperature is low and automatic

warming-up is carried out, cancel it by using the

fuel control dial after starting the engine.

Ylfi77fiAl

20-60

a

Loading...

Loading...