DISASSEMBLY AND ASSEMBLY

BUCKET

INSTALLATION OF BUCKET

ASSEMBLY

l

Carry out installation in the reverse order to

removal.

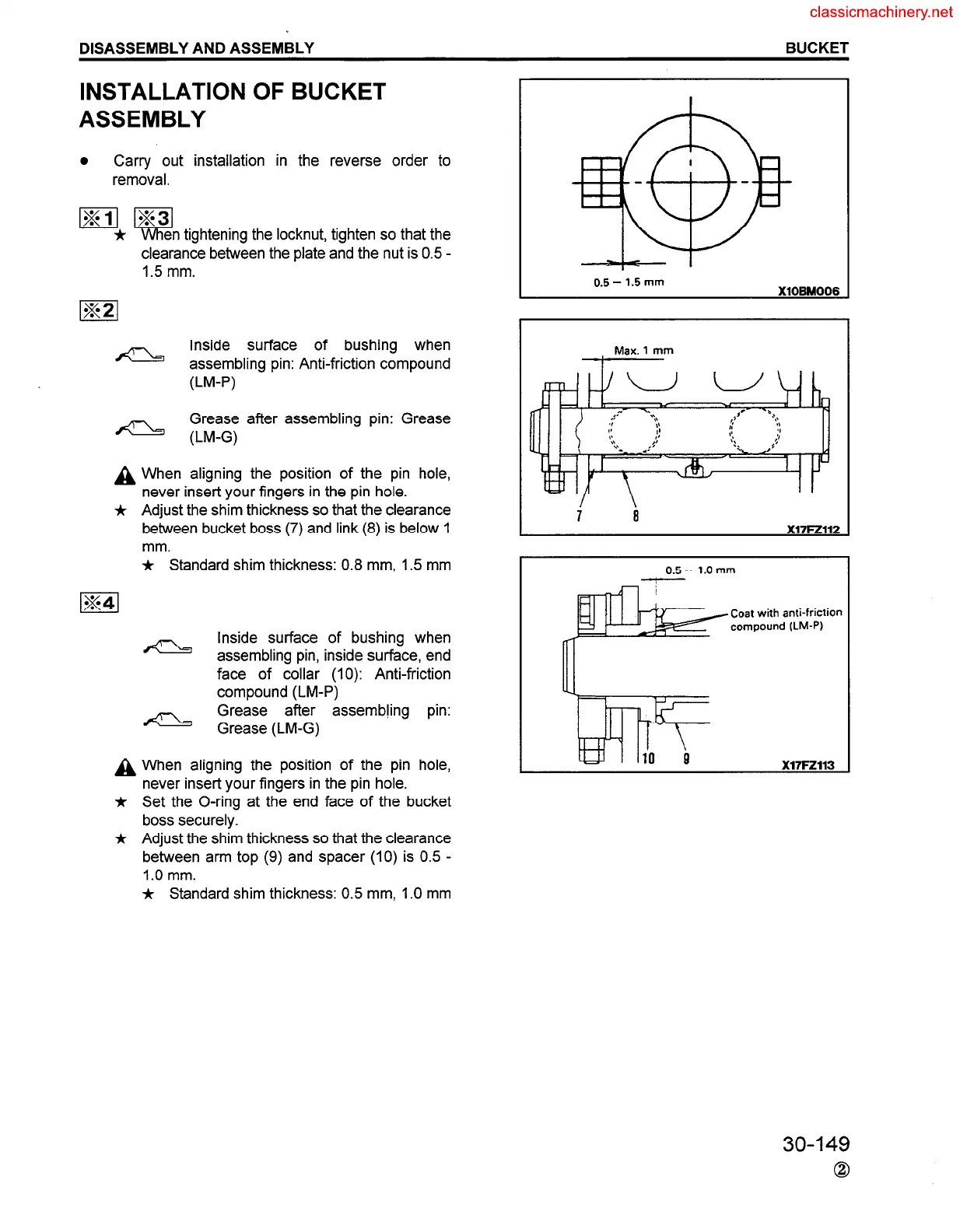

en tightening the locknut, tighten so that the

clearance between the plate and the nut is 0.5 -

1.5 mm.

-

Inside surface of bushing when

assembling pin: Anti-friction compound

(LM-P)

Grease after assembling pin: Grease

- (LM-G)

A When aligning the position of the pin hole,

never insert your fingers in the pin hole.

*

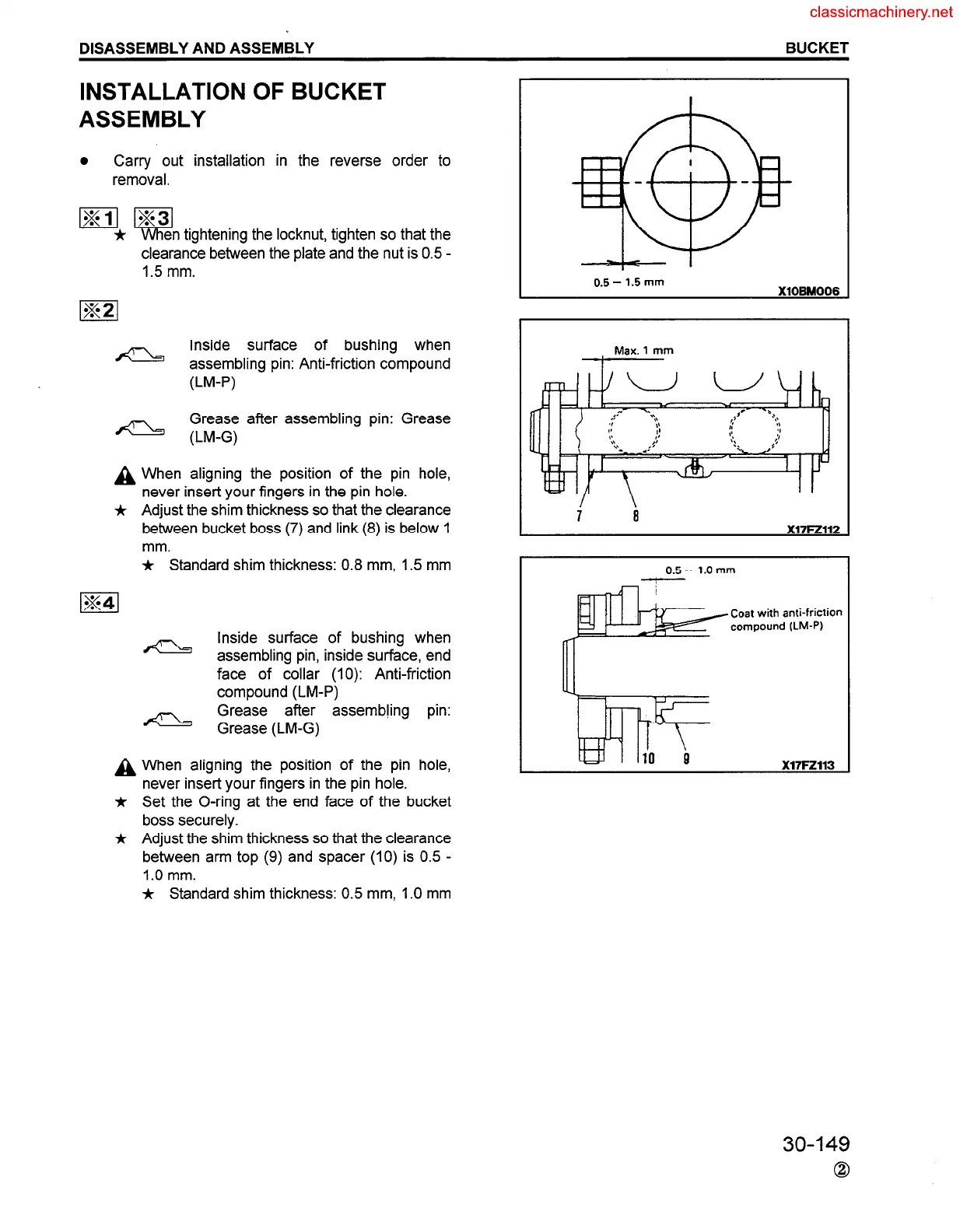

Adjust the shim thickness so that the clearance

between bucket boss (7) and link (8) is below 1

mm.

* Standard shim thickness: 0.8 mm, 1.5 mm

m

-

Inside surface of bushing when

assembling pin, inside surface, end

face of collar (10): Anti-friction

compound (LM-P)

Grease after assembkng pin:

- Grease (LM-G)

A When aligning the position of the pin hole,

never insert your fingers in the pin hole.

*

*

Set the O-ring at the end face of the bucket

boss securely.

Adjust the shim thickness so that the clearance

between arm top (9) and spacer (10) is 0.5 -

1.0 mm.

j, Standard shim thickness: 0.5 mm, 1 .O mm

0.5 - 1.5 mm

XlOBM006

Max. 1 mm

0.5- l.Omm

Coat with anti-friction

compound ILM-P)

30-I 49

0

Loading...

Loading...