TROUBLESHOOTING

M-22

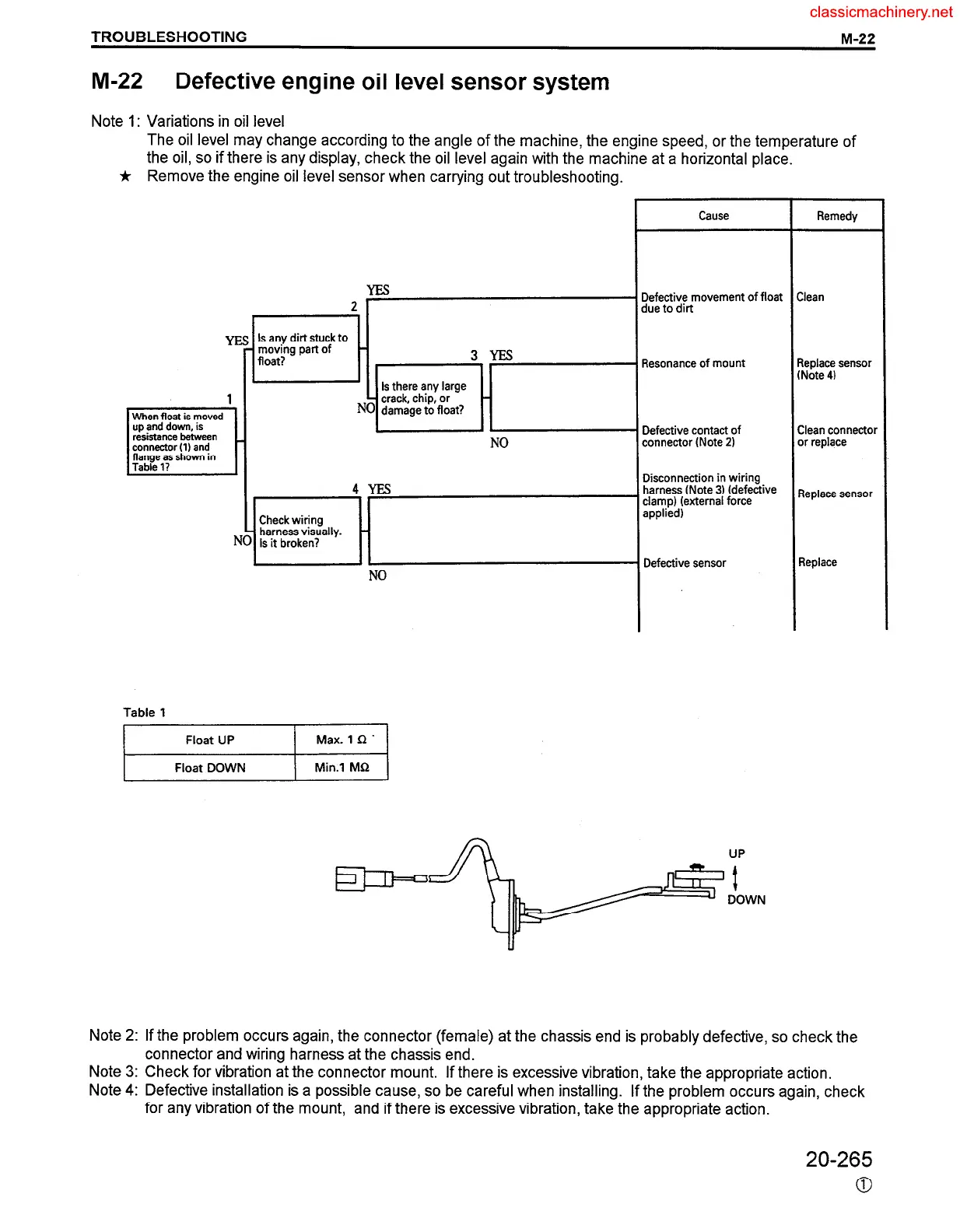

M-22 Defective engine oil level sensor system

Note 1: Variations in oil level

The oil level may change according to the angle of the machine, the engine speed, or the temperature of

the oil, so if there is any display, check the oil level again with the machine at a horizontal place.

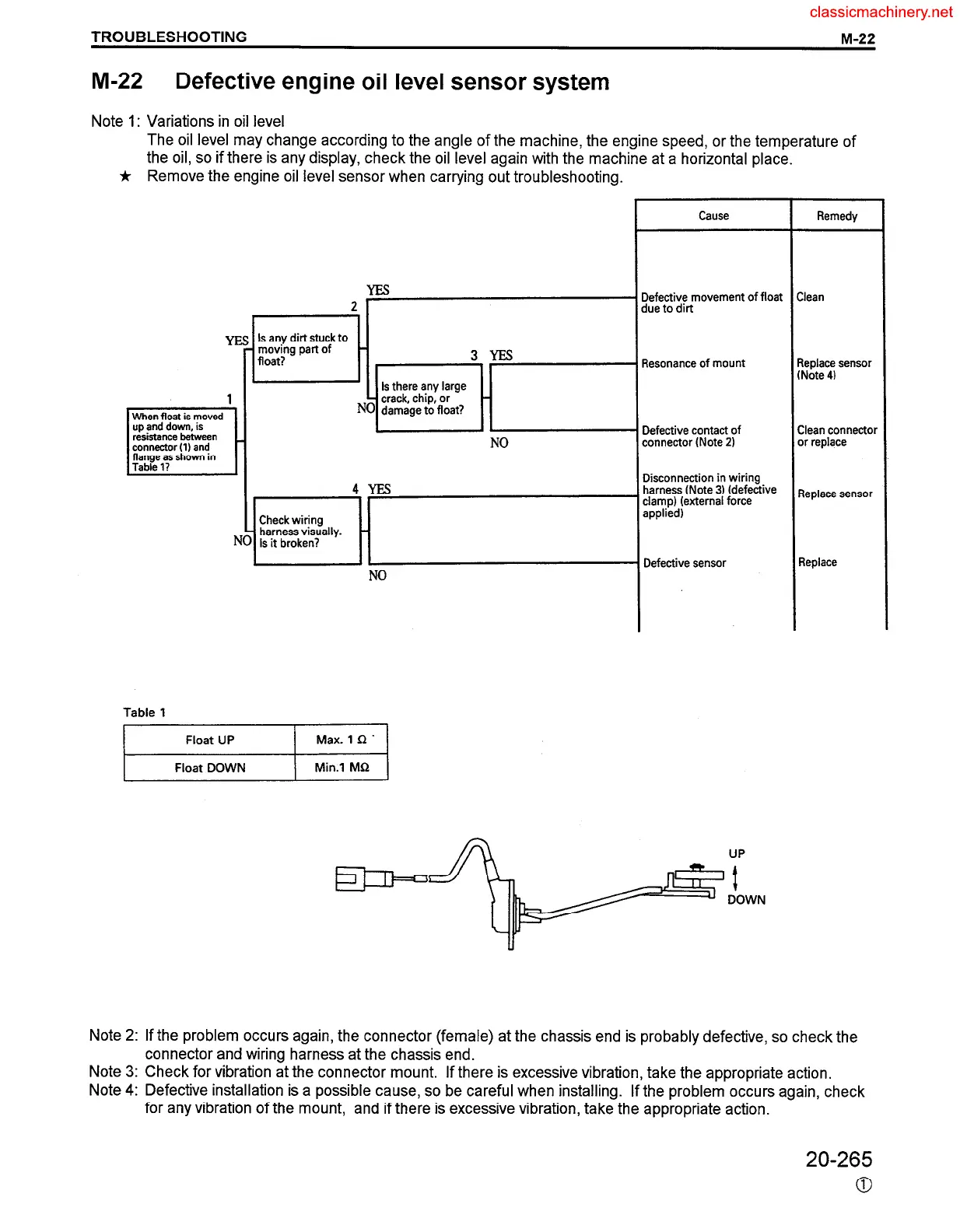

* Remove the engine oil level sensor when carrying out troubleshooting.

‘I

resistance between

connector (11 and

flange as shown in

Es

I

NO

I

I I

NO

Check wiring

harness visually.

Is it broken?

H

I

II

NO

Cause

Defective movement of float

due to dirt

Resonance of mount

Defective contact of

connector (Note 2)

Disconnection in wiring

harness (Note 3) (defective

clamp) (external force

applied)

Defective sensor

UP

lean

eplace sensor

Jote 4)

lean connector

r replace

,eplace sensor

leplace

Note 2: If the problem occurs again, the connector (female) at the chassis end is probably defective, so check the

connector and wiring harness at the chassis end.

Note 3: Check for vibration at the connector mount. If there is excessive vibration, take the appropriate action.

Note 4: Defective installation is a possible cause, so be careful when installing. If the problem occurs again, check

for any vibration of the mount,

and if there is excessive vibration, take the appropriate action.

20-265

0

Loading...

Loading...