DISASSEMBLY AND ASSEMBLY

TRACK SHOE

REMOVAL OF TRACK SHOE

ASSEMBLY

1.

2.

3.

4.

5.

Stop machine at a point where master pin is

midway between idler and carrier roller, and where

there is space to lay out track assembly on ground.

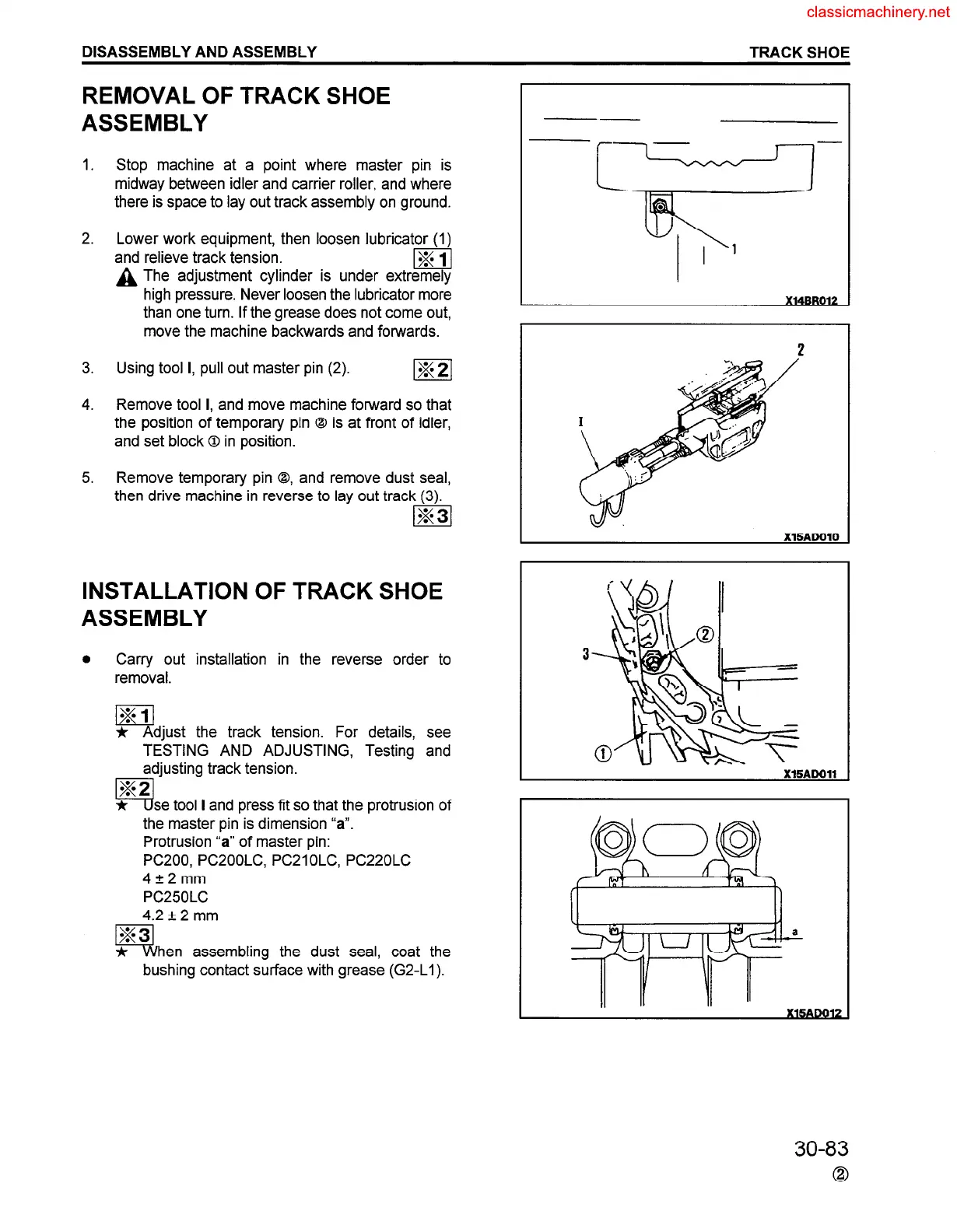

Lower work equipment, then loosen lubricator (1)

and relieve track tension.

m/

A The adjustment cylinder is under extremely

high pressure. Never loosen the lubricator more

than one turn. If the grease does not come out,

move the machine backwards and forwards.

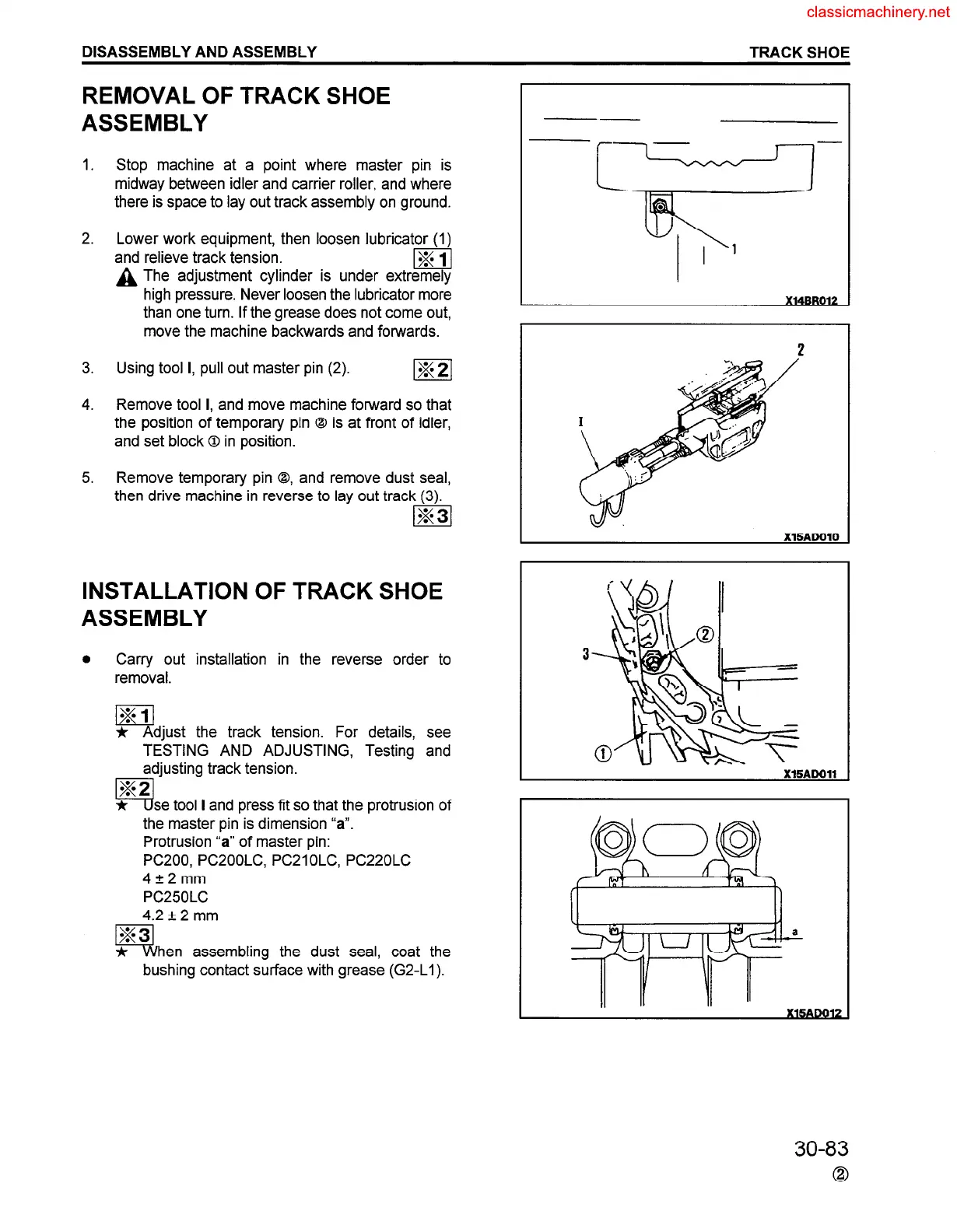

Using tool I, pull out master pin (2).

m

Remove tool I, and move machine forward so that

the position of temporary pin 0 is at front of idler,

and set block 0 in position.

Remove temporary pin Q, and remove dust seal,

then drive machine in reverse to lay out track (3).

INSTALLATION OF TRACK SHOE

ASSEMBLY

0

Carry out installation in the reverse order to

removal.

* Adjust the track tension. For details, see

TESTING AND ADJUSTING, Testing and

adjusting track tension.

se tool I and press fit so that the protrusion of

the master pin is dimension “a”.

Protrusion ‘a” of master pin:

PC200, PC2OOLC, PC21 OLC, PC22OLC

4*2mm

PC25OLC

4.2 + 2 mm

hen assembling the dust seal, coat the

bushing contact surface with grease (G2-Ll).

30-83

0

Loading...

Loading...