TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO

TESTING AND ADJUSTING PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

TESTING AND ADJUSTING LS

VALVE OUTPUT PRESSURE (SERVO

PISTON INPUT PRESSURE) AND LS

DIFFERENTIAL PRESSURE

*

Hydraulic oil temperature when measuring: 45 - 55°C

Measuring

1.

Measuring LS valve output pressure (servo piston

input pressure)

1)

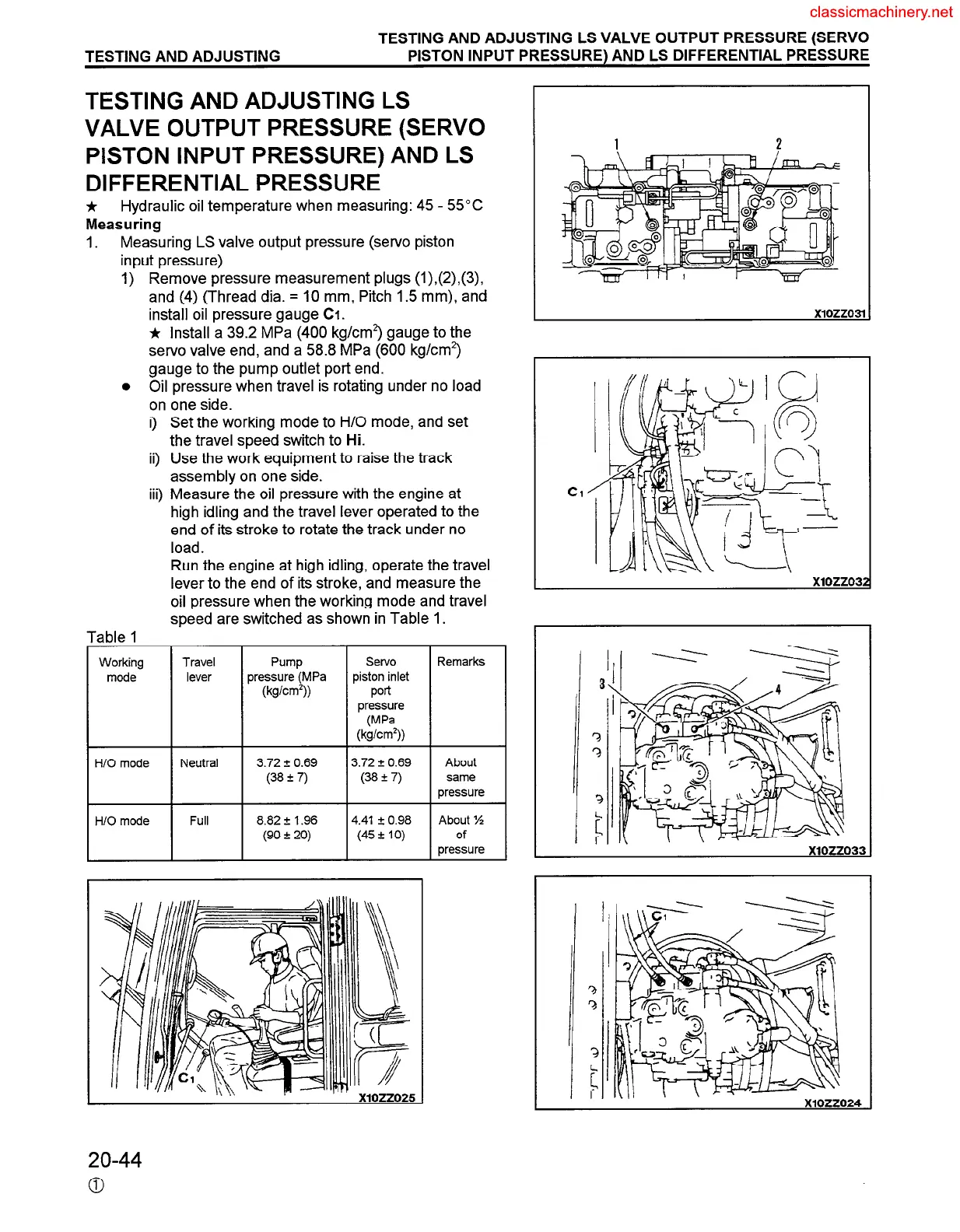

Remove pressure measurement plugs (l),(2),(3),

and (4) (Thread dia. = 10 mm, Pitch 1.5 mm), and

install oil pressure gauge Cl.

j, Install a 39.2 MPa (400 kg/cm? gauge to the

servo valve end, and a 58.8 MPa (600 kg/cm?

gauge to the pump outlet port end.

l

Oil pressure when travel is rotating under no load

on one side.

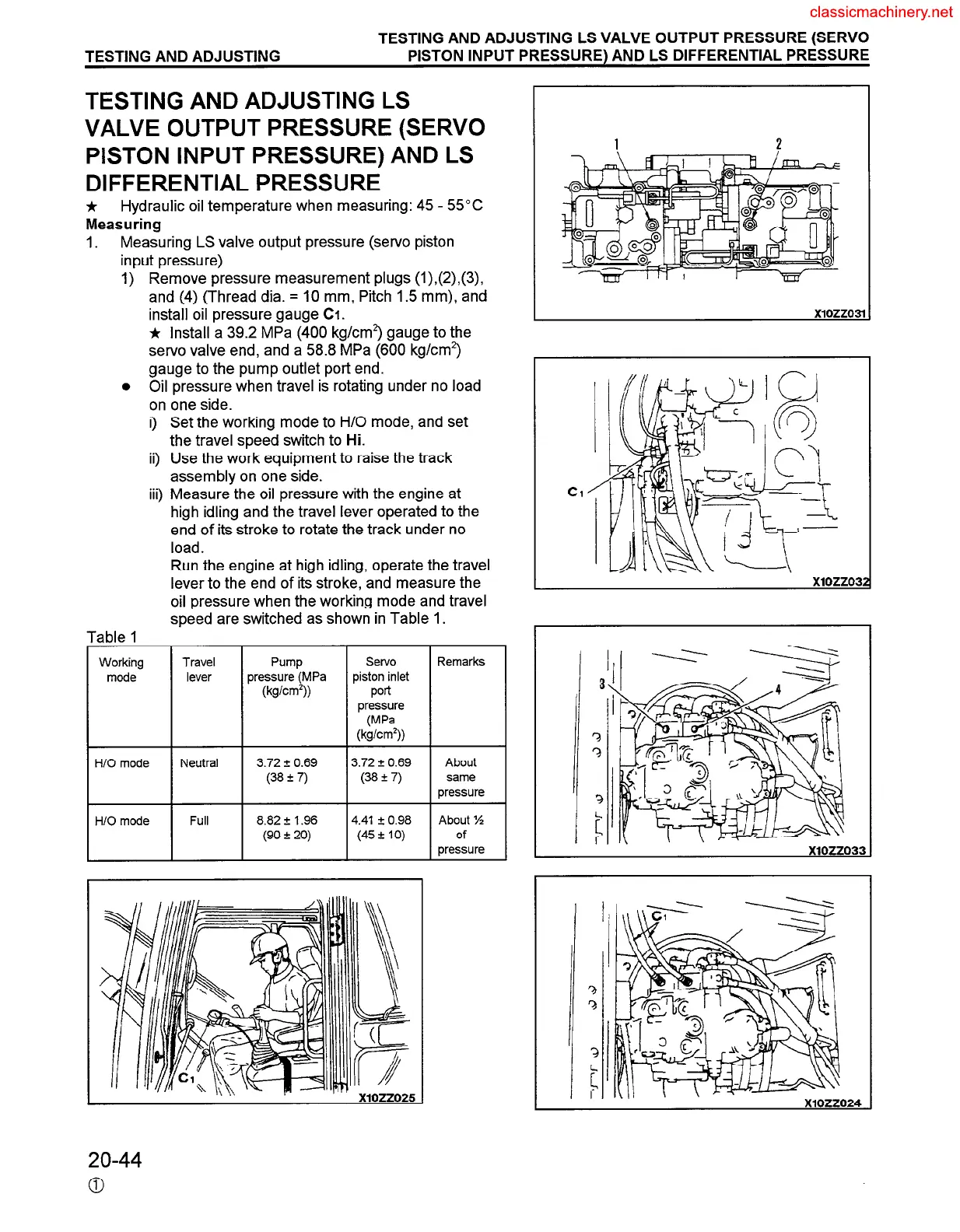

i) Set the working mode to H/O mode, and set

the travel speed switch to Hi.

ii) Use the work equipment to raise the track

assembly on one side.

iii) Measure the oil pressure with the engine at

high idling and the travel lever operated to the

end of its stroke to rotate the track under no

load.

Run the engine at high idling, operate the travel

lever to the end of its stroke, and measure the

oil pressure when the working mode and travel

speed are switched as shown in Table 1.

-able 1

Working

Travel

mode

lever

l-

H/O mode

Neutral

HI0 mode Full

Pump

pressure (MPa

(kg/cm*))

3.72 f 0.69

3.72 f 0.69

(38 f 7)

(38 f 7)

8.82 f 1.96

(90 f 20)

Servo

piston inlet

Port

pressure

(MPa

(kg/cm*))

4.41 f 0.98

(45+ 10)

Remarks

About

same

pressure

About %

of

3ressure

-

Cl’

20-44

0

Loading...

Loading...