DISASSEMBLY AND ASSEMBLY

IDLER

DISASSEMBLY OF IDLER

ASSEMBLY

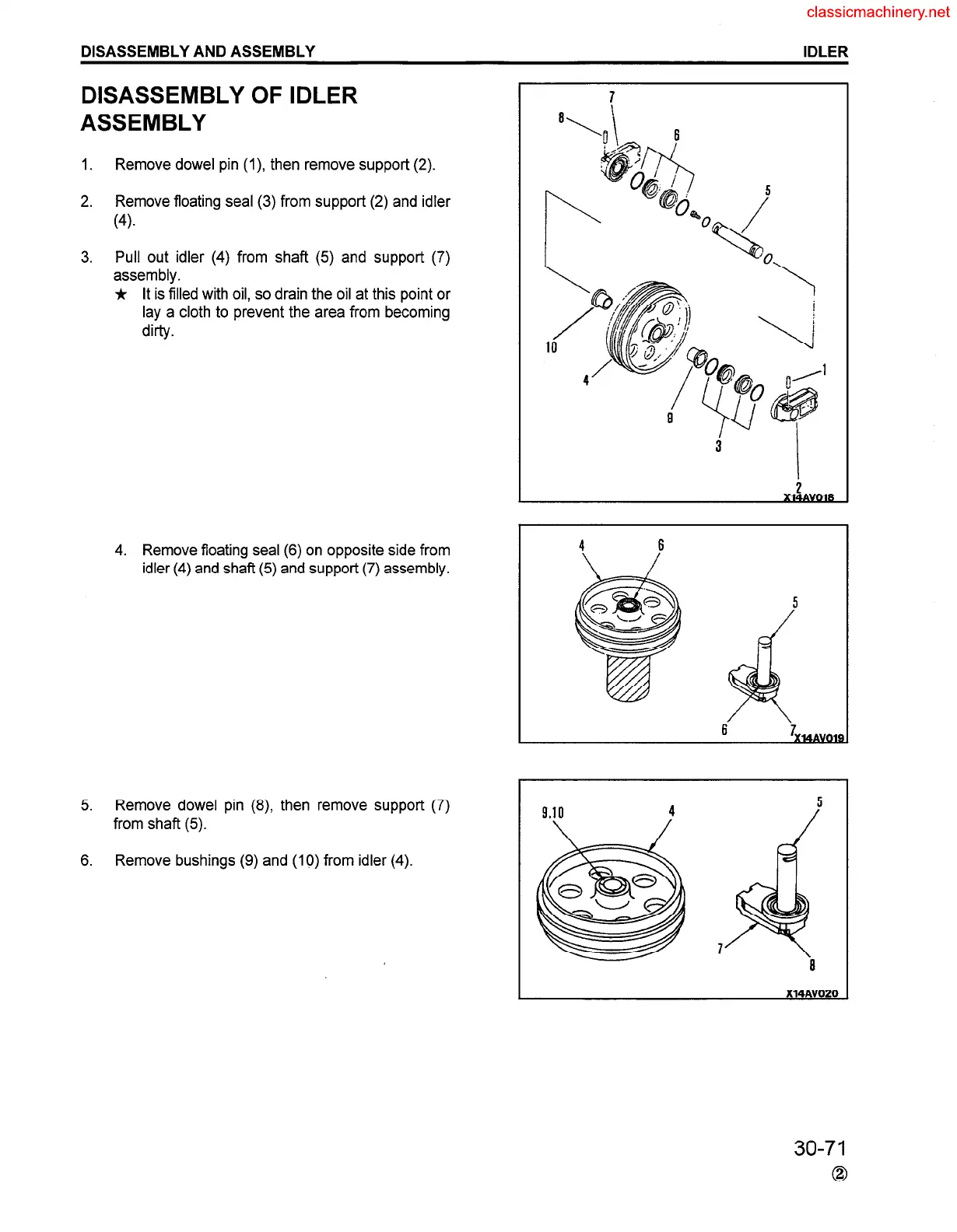

1. Remove dowel pin (I), then remove support (2).

2. Remove floating seal (3) from support (2) and idler

(4).

3. Pull out idler (4) from shaft (5) and support (7)

assembly.

* It is filled with oil, so drain the oil at this point or

lay a cloth to prevent the area from becoming

dirty.

4. Remove floating seal (6) on opposite side from

idler (4) and shaft (5) and support (7) assembly.

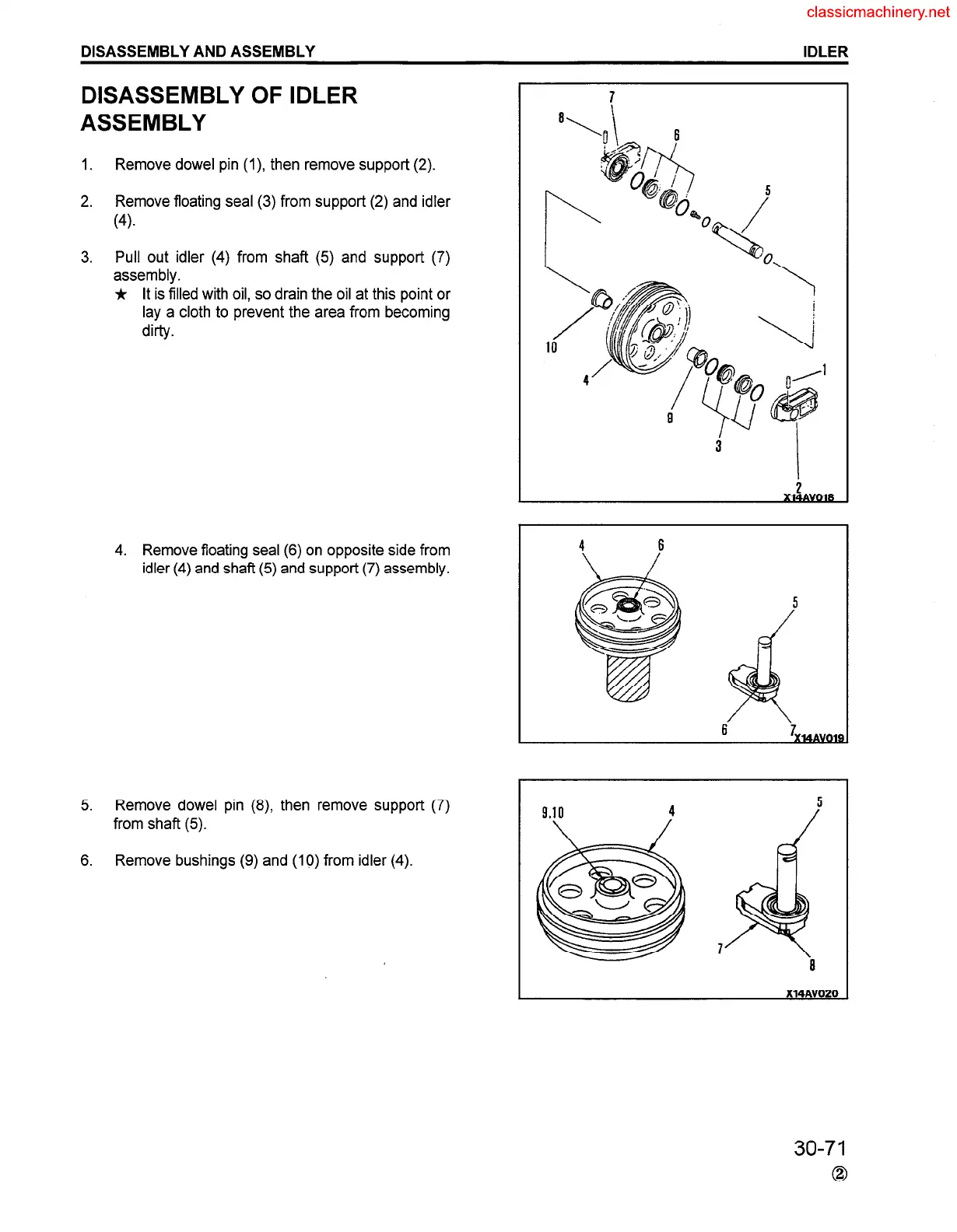

5.

6.

Remove dowel pin (8), then remove support (7)

from shaft (5).

Remove bushings (9) and (19) from idler (4).

30-71

0

Loading...

Loading...