DISASSEMBLY AND ASSEMBLY

MAIN PUMP

ASSEMBLY OF MAIN PUMP

ASSEMBLY (HPV95 + 95)

Clean all parts, remove all burrs, and check for dirt or

damage. Coat the rotating and sliding surfaces of all

parts with engine oil (EOI O-CD) before installing.

Always check the following parts before assembling.

1)

ii)

iii)

l

1.

Check contact of cradle and rocker cam (for details,

see procedure for checking contact)

Check contact between cylinder block and valve

plate (for details, see procedure for checking

contact).

Check contact between valve plate and end cap (for

details, see procedure for checking contact).

Assembly of front pump assembly

Shaft and cradle assembly

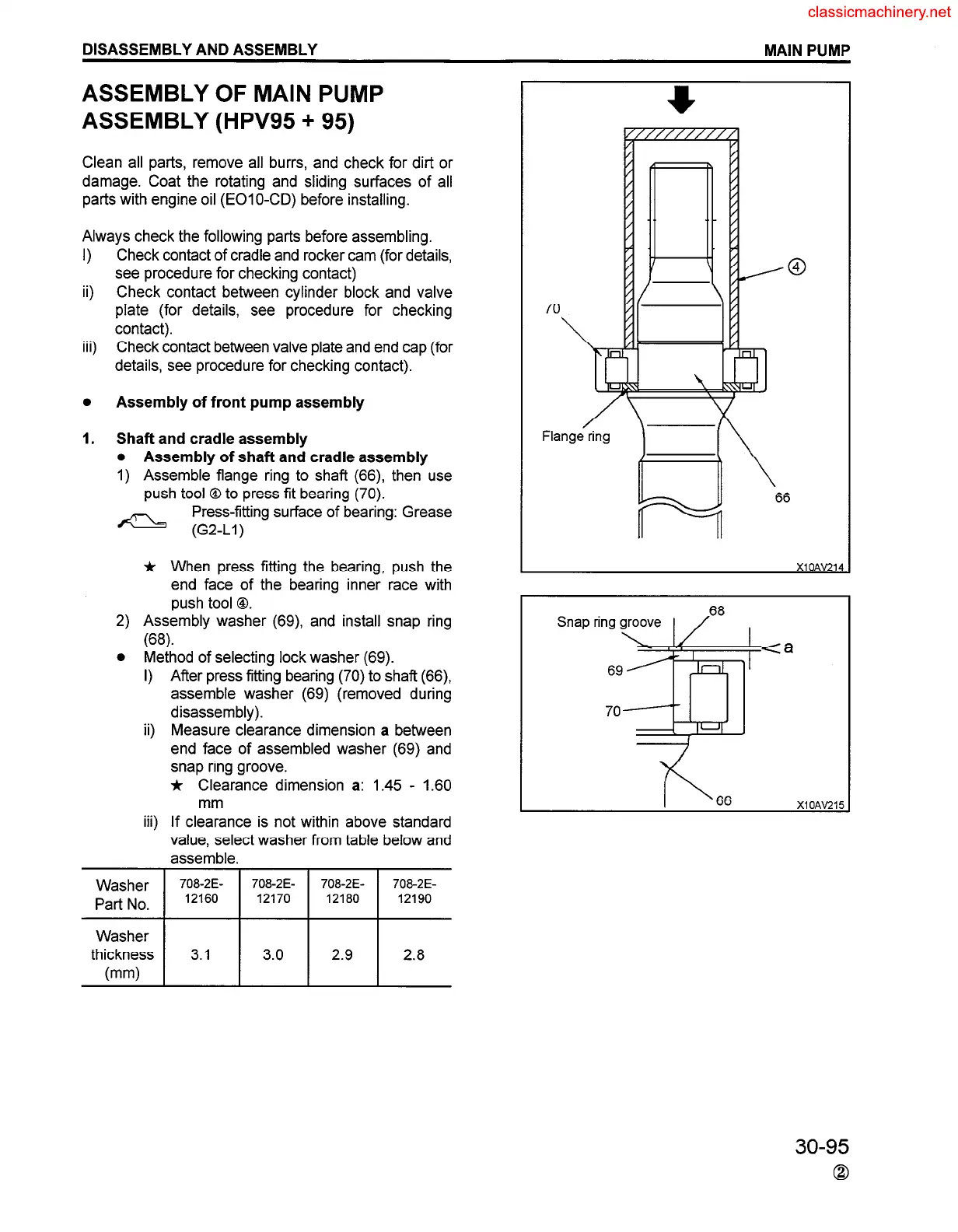

l Assembly of shaft and cradle assembly

1) Assemble flange ring to shaft (66) then use

push tool @to press fit bearing (70).

Press-fitting surface of bearing: Grease

- (G2-Ll)

2)

0

* When press fitting the bearing, push the

end face of the bearing inner race with

push tool @.

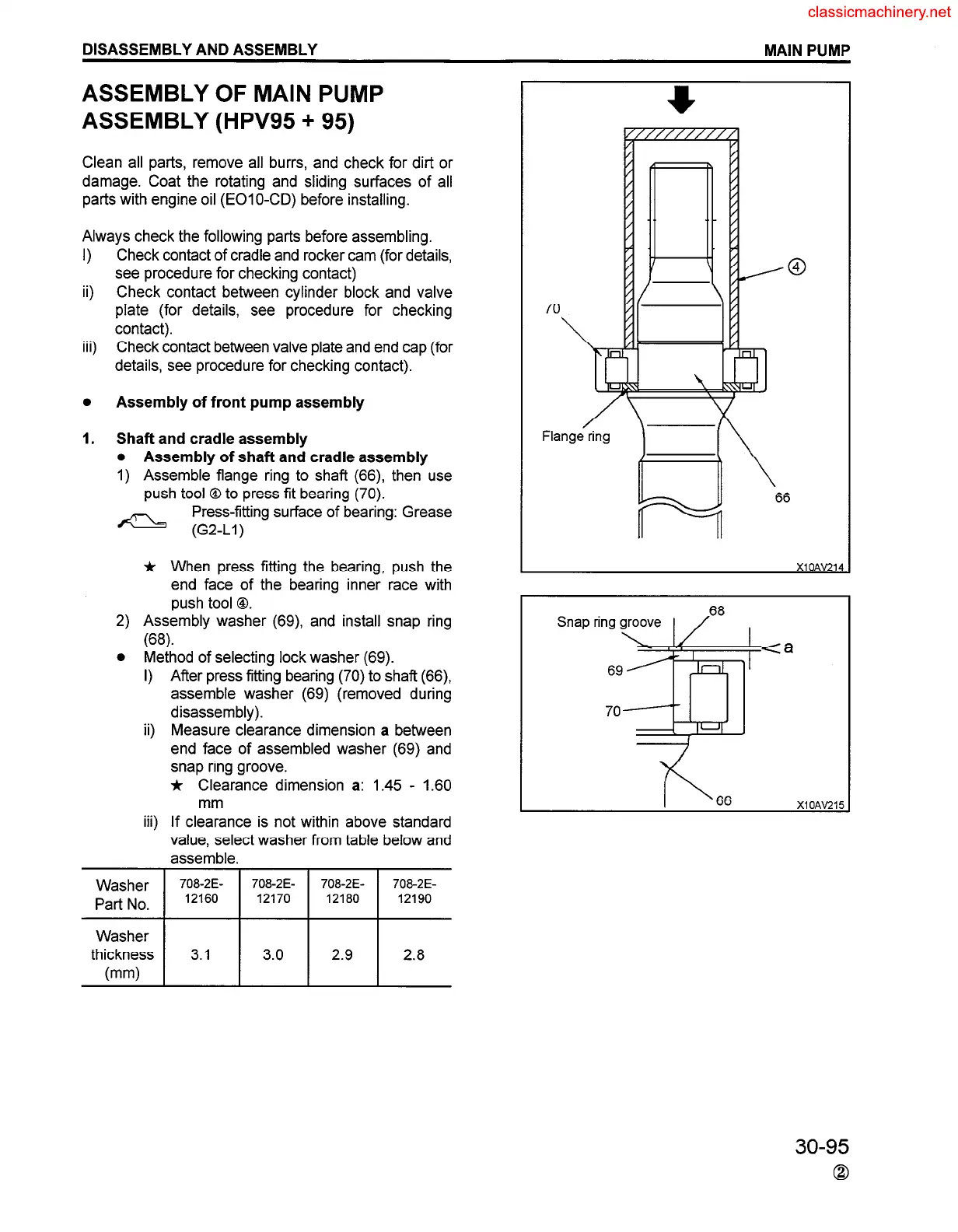

Assembly washer (69), and install snap ring

(68).

Method of selecting lock washer (69).

I) After press fitting bearing (70) to shaft (66)

assemble washer (69) (removed during

disassembly).

ii) Measure clearance dimension a between

end face of assembled washer (69) and

snap ring groove.

j, Clearance dimension a: 1.45 - 1.60

mm

iii) If clearance is not within above standard

value, select washer from table below and

assemble.

Washer

Part No.

XlOAV214

Snap ring groove

66

XlOAV215

Washer

thickness

(mm)

3.1

3.0 2.9

2.8

30-95

0

Loading...

Loading...