TESTING AND ADJUSTING

TESTING AND ADJUSTING TRACK SHOE TENSION

TESTING AND ADJUSTING TRACK

SHOE TENSION

TESTING

1.

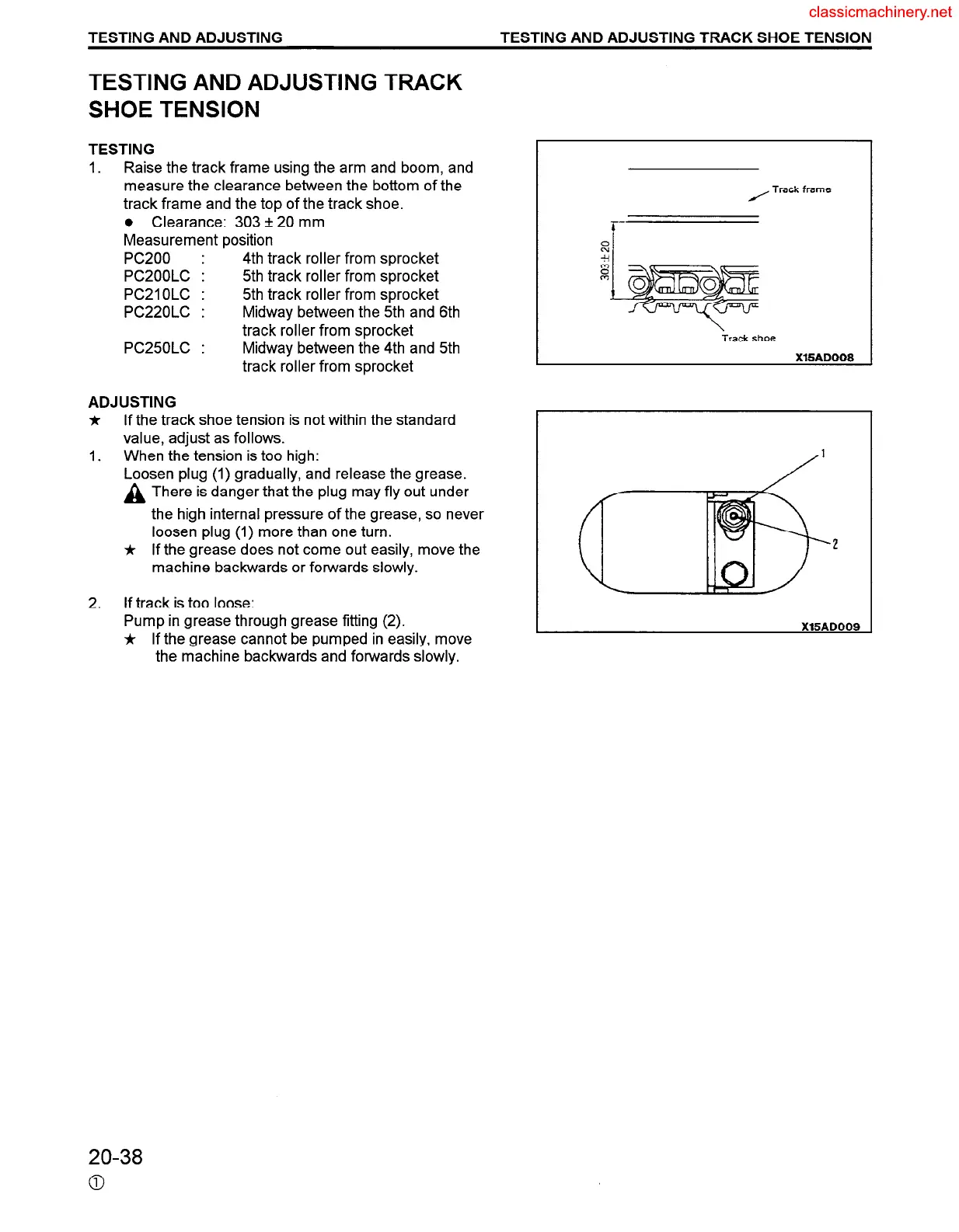

Raise the track frame using the arm and boom, and

measure the clearance between the bottom of the

track frame and the top of the track shoe.

0 Clearance: 303 f 20 mm

Measurement position

PC200 :

4th track roller from sprocket

PC2OOLC :

5th track roller from sprocket

PC21OLC :

5th track roller from sprocket

PC22OLC :

Midway between the 5th and 6th

track roller from sprocket

PC25OLC :

Midway between the 4th and 5th

track roller from sprocket

ADJUSTING

*

If the track shoe tension is not within the standard

value, adjust as follows.

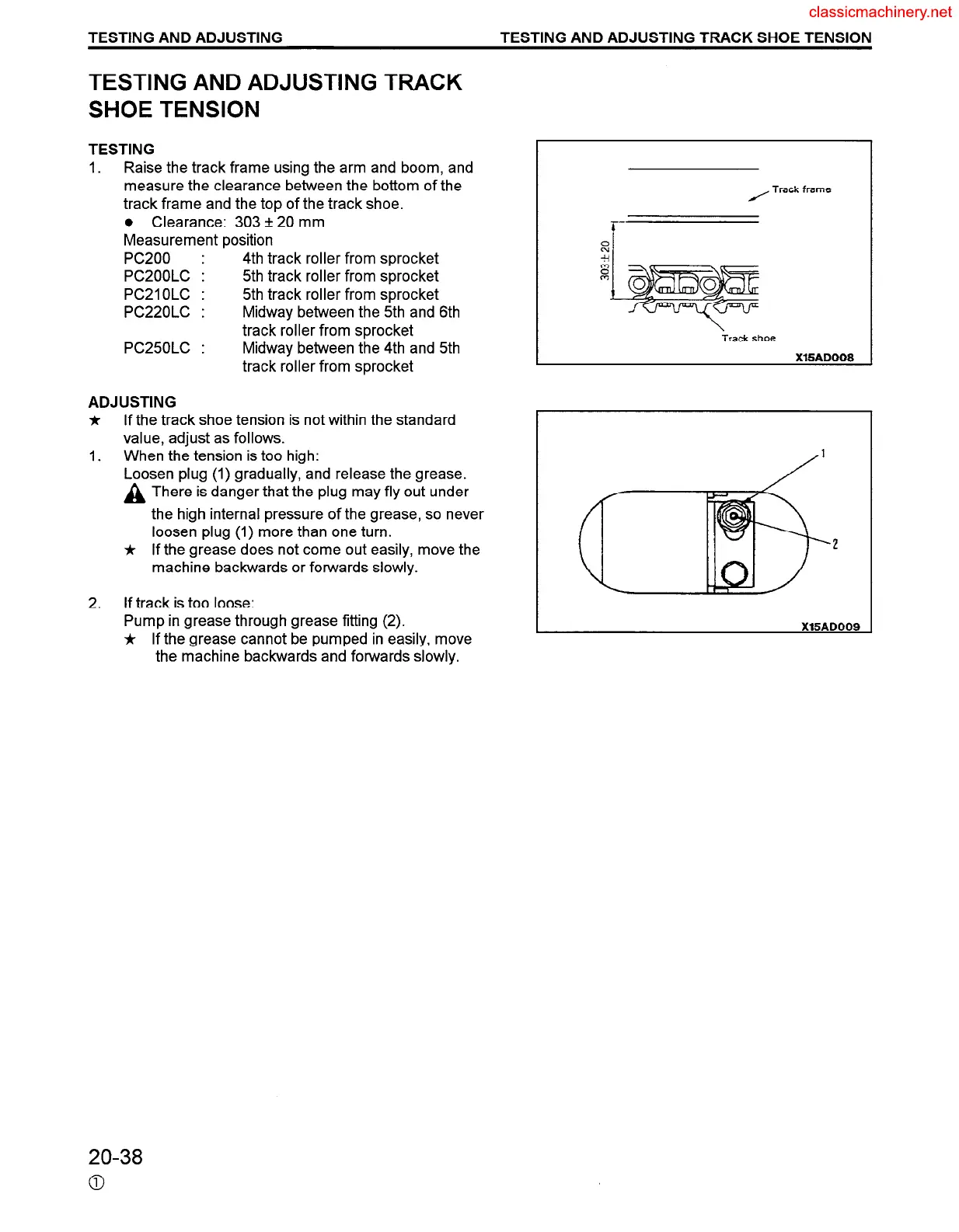

1.

When the tension is too high:

Loosen plug (1) gradually, and release the grease.

A There is danger that the plug may fly out under

the high internal pressure of the grease, so never

loosen plug (1) more than one turn.

* If the grease does not come out easily, move the

machine backwards or forwards slowly.

2.

If track is too loose:

Pump in grease through grease fitting (2).

+r If the grease cannot be pumped in easily, move

the machine backwards and forwards slowly.

/

Track frame

\

Track shoe

X15AD008

I

X15AD009

20-38

a

Loading...

Loading...