DISASSEMBLY AND ASSEMBLY

BOOM CYLINDER

INSTALLATION OF BOOM

CYLINDER ASSEMBLY

Carry out installation in the reverse order to

removal.

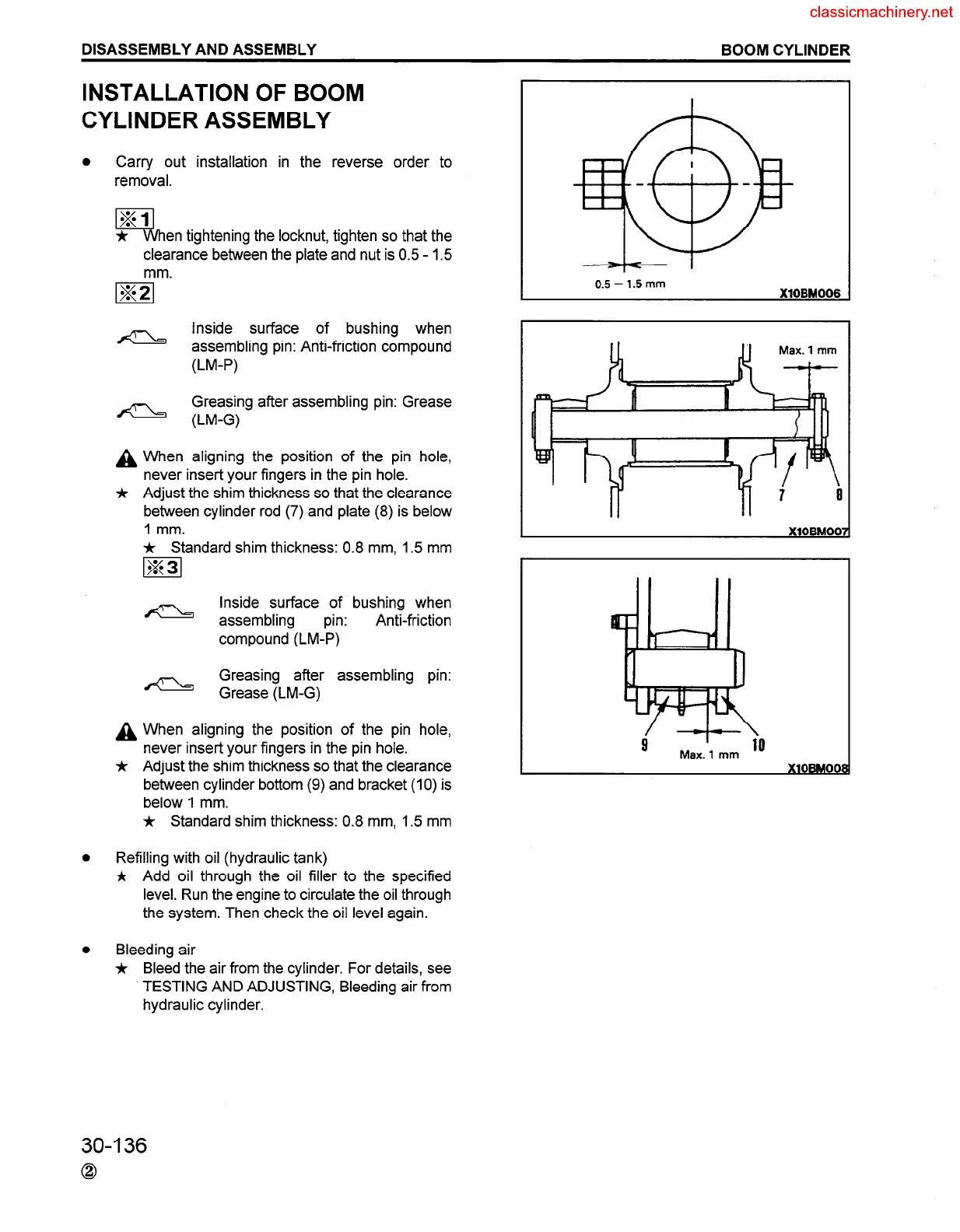

en tightening the locknut, tighten so that the

clearance between the plate and nut is 0.5 - 1.5

mm.

m

A

Inside surface of bushing when

assembling pin: Anti-friction compound

(LM-P)

Greasing after assembling pin: Grease

A (LM-G)

A When aligning the position of the pin hole,

never insert your fingers in the pin hole.

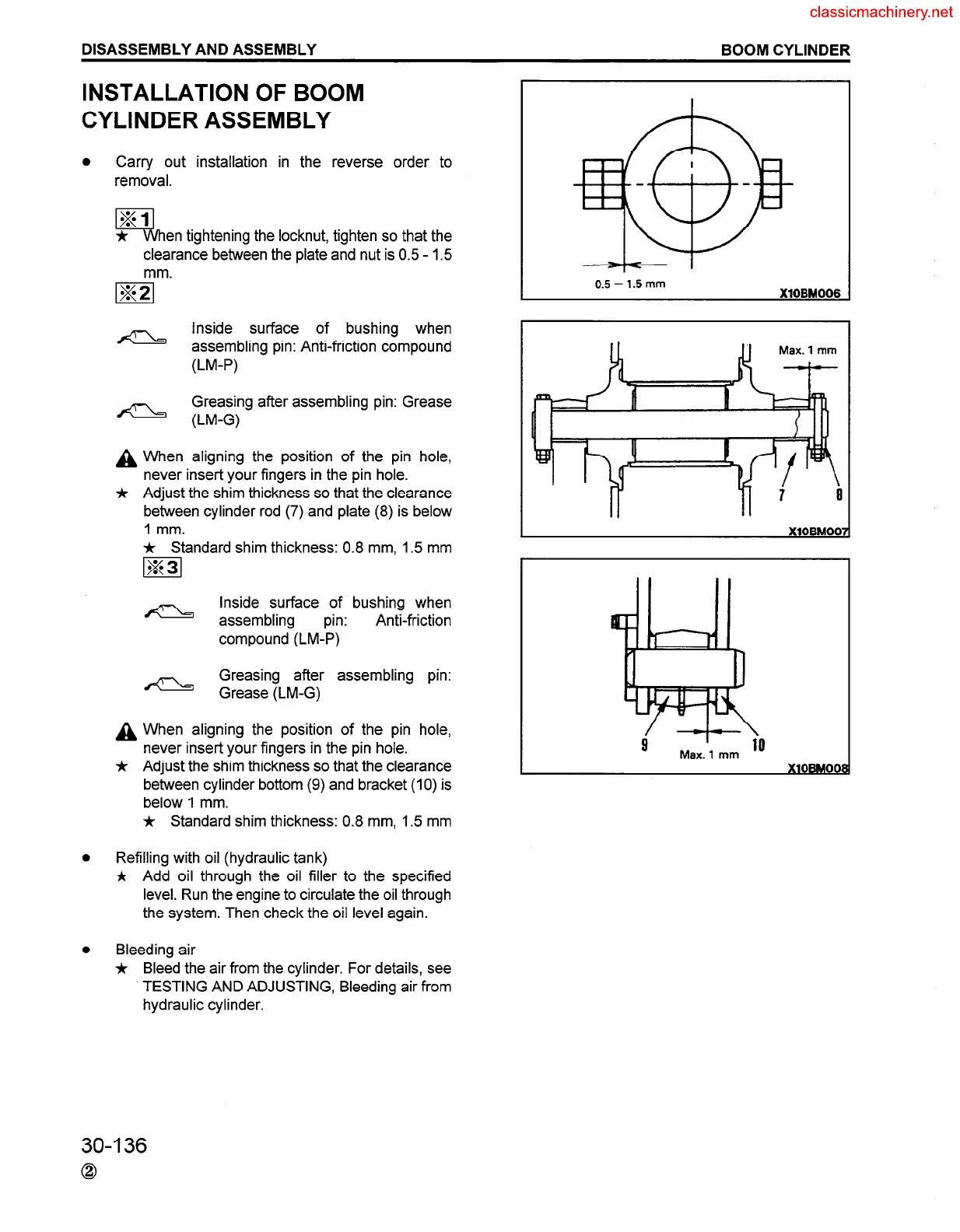

* Adjust the shim thickness so that the clearance

between cylinder rod (7) and plate (8) is below

1 mm.

* Standard shim thickness: 0.8 mm, 1.5 mm

m

Inside surface of bushing when

a assembling

pin:

Anti-friction

compound (LM-P)

Greasing after assembling pin:

- Grease (LM-G)

A When aligning the position of the pin hole,

never insert your fingers in the pin hole.

* Adjust the shim thickness so that the clearance

between cylinder bottom (9) and bracket (IO) is

below 1 mm.

* Standard shim thickness: 0.8 mm, 1.5 mm

Refilling with oil (hydraulic tank)

j, Add oil through the oil filler to the specified

level. Run the engine to circulate the oil through

the system. Then check the oil level again.

Bleeding air

j, Bleed the air from the cylinder. For details, see

TESTING AND ADJUSTING, Bleeding air from

hydraulic cylinder.

0.5 - 1.5 mm

XlOBM006

I

Max. 1 mm

io

30-136

0

Loading...

Loading...