TROUBLESHOOTING

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING

PROCEDURE

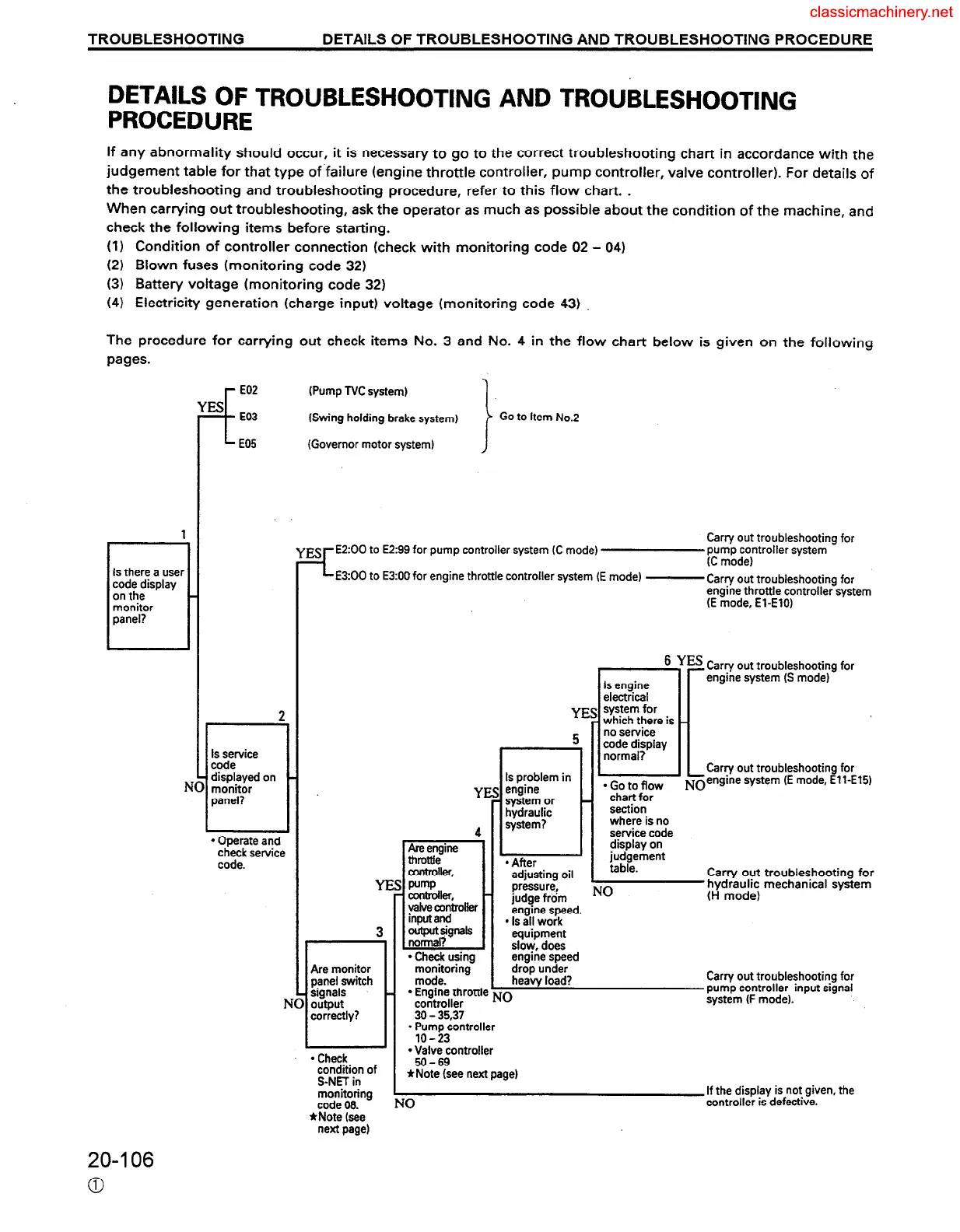

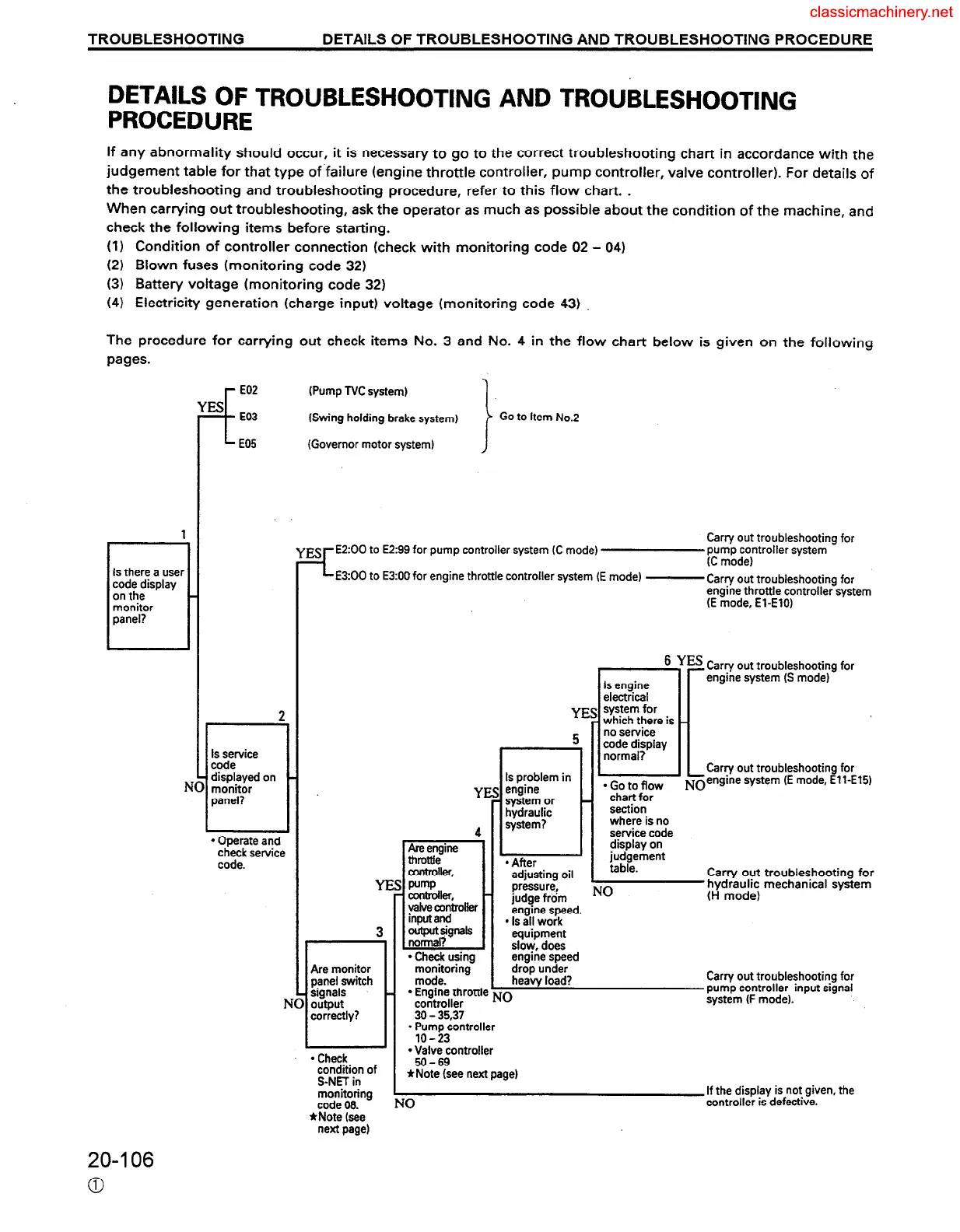

If any abnormality should occur, it is necessary to go to the correct troubleshooting chart in accordance with the

judgement table for that type of failure (engine throttle controller, pump controller, valve controller). For details of

the troubleshooting and troubleshooting procedure, refer to this flow chart. .

When carrying out troubleshooting, ask the operator as much as possible about the condition of the machine, and

check the following items before starting.

(1)

Condition of controller connection (check with monitoring code 02 - 04)

(2)

Blown fuses (monitoring code 32)

(3)

Battery voltage (monitoring code 32)

(4)

Electricity generation (charge input) voltage (monitoring code 43)

The procedure for carrying out check items No. 3 and No. 4 in the flow chart below is given on the following

pages.

Is there a user

~n~h~isplay

monitor

panel?

f

E02

(Pump TVC system)

ES

E03

(Swing holding brake system)

Go to Item No.2

L E05

(Governor motor system)

E2:OO to E2:99 for pump controller system (C mode)

Carry out troubleshooting for

~;rnn;~;troller system

7

I

I

Is service

code

displayed on

1 monitor

panel?

l Operate and

check service

code.

LE3:00 to E3:OO for engine throttle controller system (E mode)

Carry out troubleshooting for

engine throttle controller-system

fE mode, El-El01

.

Are monitor

panel switch

signals

output

correctly?

I

*Check

condition of

S-NET in

monitoring

code 08.

*Note (see

next page)

1

l Check using

monitoring

mode.

l Engine thron

(Es

I

1

tle h

controller

30 - 35‘37

YE

5

l After

adjusting oil

pressure!

judge from

engine speed.

l Is all work

equipment

slow, does

engine speed

drop under_

Is engine

electrical

system for

which there is

no service

;o;erJ;;pfay

l Go to flow

chart for

section

where is no

service code

display on

j$,ment

‘ES Carry out troubleshooting for

r

engine system (S mode)

LCarry out troubleshooting for

NOengrne system fE mode, Eli-E15)

Car.ry ?ut troubleshooting for

0

nyaraulrc mechanrcal system

(H mode)

Carry out troubleshooting for

pump controuer rnput srgnar

system (F mode).

l rump controller

lo-23

l Valve controller

50-69

heavy load?

10

*Note-(see next page)

NO

If the display is not given, the

controller is defective.

20-106

0

Loading...

Loading...