DISASSEMBLY AND ASSEMBLY

SWING MOTOR

REMOVAL OF SWING MOTOR

ASSEMBLY

A

Lower the work equipment completely to the ground

and stop the engine. Loosen the oil filler cap slowly

to release the pressure inside the hydraulic tank.

Then set the safety lock lever to the LOCK position.

I.

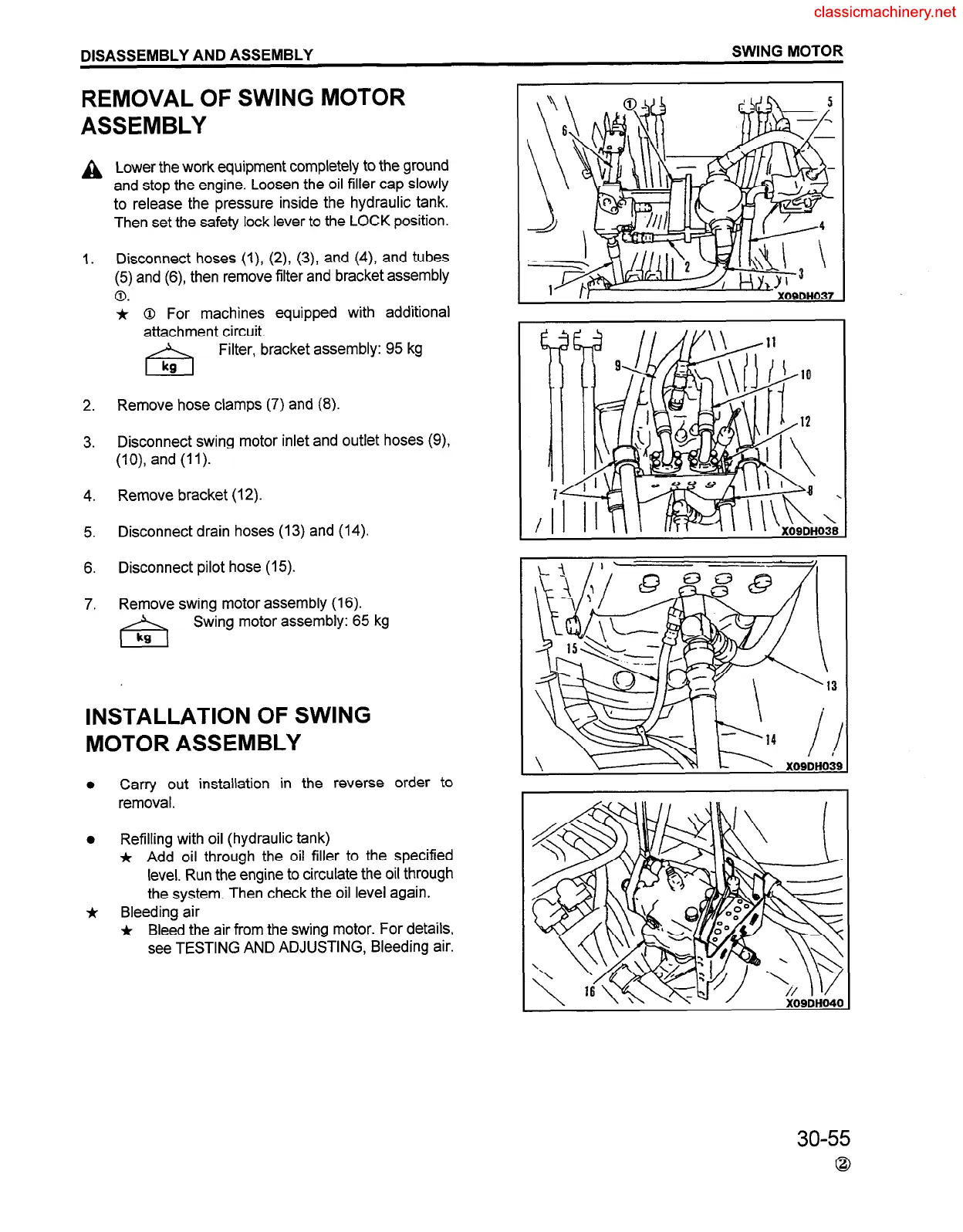

Disconnect hoses (I), (2), (3), and (4), and tubes

(5) and (6) then remove filter and bracket assembly

0.

* 0 For machines equipped with additional

attachment circuit.

&

Filter, bracket assembly: 95 kg

kg

2.

3.

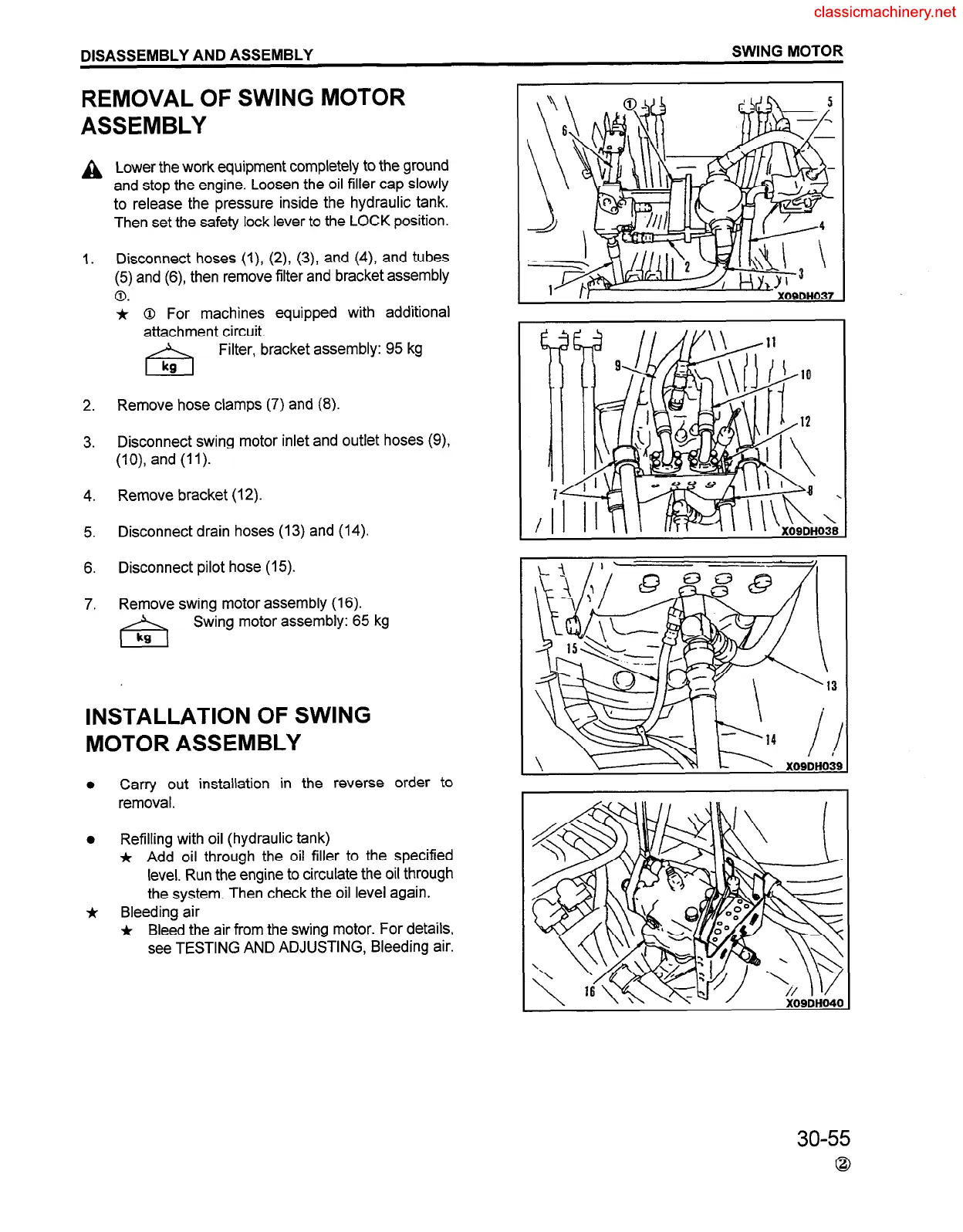

Remove hose clamps (7) and (8).

Disconnect swing motor inlet and outlet hoses (9)

(IO), and (11).

4.

Remove bracket (12).

5.

Disconnect drain hoses (13) and (14).

6.

Disconnect pilot hose (15).

7.

Remove swing motor assembly (16).

Swing motor assembly: 65 kg

INSTALLATION OF SWING

MOTOR ASSEMBLY

0

Carry out installation in the reverse order to

removal.

0

Refilling with oil (hydraulic tank)

* Add oil through the oil filler to the specified

level. Run the engine to circulate the oil through

the system. Then check the oil level again.

k Bleeding air

*

Bleed the air from the swing motor. For details,

see TESTING AND ADJUSTING, Bleeding air.

30-55

0

Loading...

Loading...