TROUBLESHOOTING

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

To maitain the performance of the machine over a

long period, and to prevent failures or other troubles

before they occur, correct operation, maintenance

and inspection, troubleshooting, and repairs must

be carried out. This section deals particularly with

correct repair procedures for mechatronics and is

aimed at improving the quality of repairs. For this

purpose, it gives sections on “Handling electric

equipment” and “Handling hydraulic equipment”

(particlularly hydraulic oil).

1. PRECAUTIONS WHEN HANDLING

ELECTRIC EQUIPMENT

1) Handling wiring harnesses and connectors

Wiring harnesses consist of wiring connecting

one component to another component, conn-

ectors used for connecting and disconnecting

one wire from another wire, and protector or

tubes used for protecting the wiring. Compared

with other electrical components fitted in boxes

or cases, wiring harnesses are more likely to be

affected by the direct effects of rain, water, heat,

or vibration. Furthemore, during inspection and

repair operation they are frequently removed and

installed again, so they are likely to suffer defor-

mation or damage. For this reason, it is nec-

ssary to be extremely careful when handling

wiring harnesses.

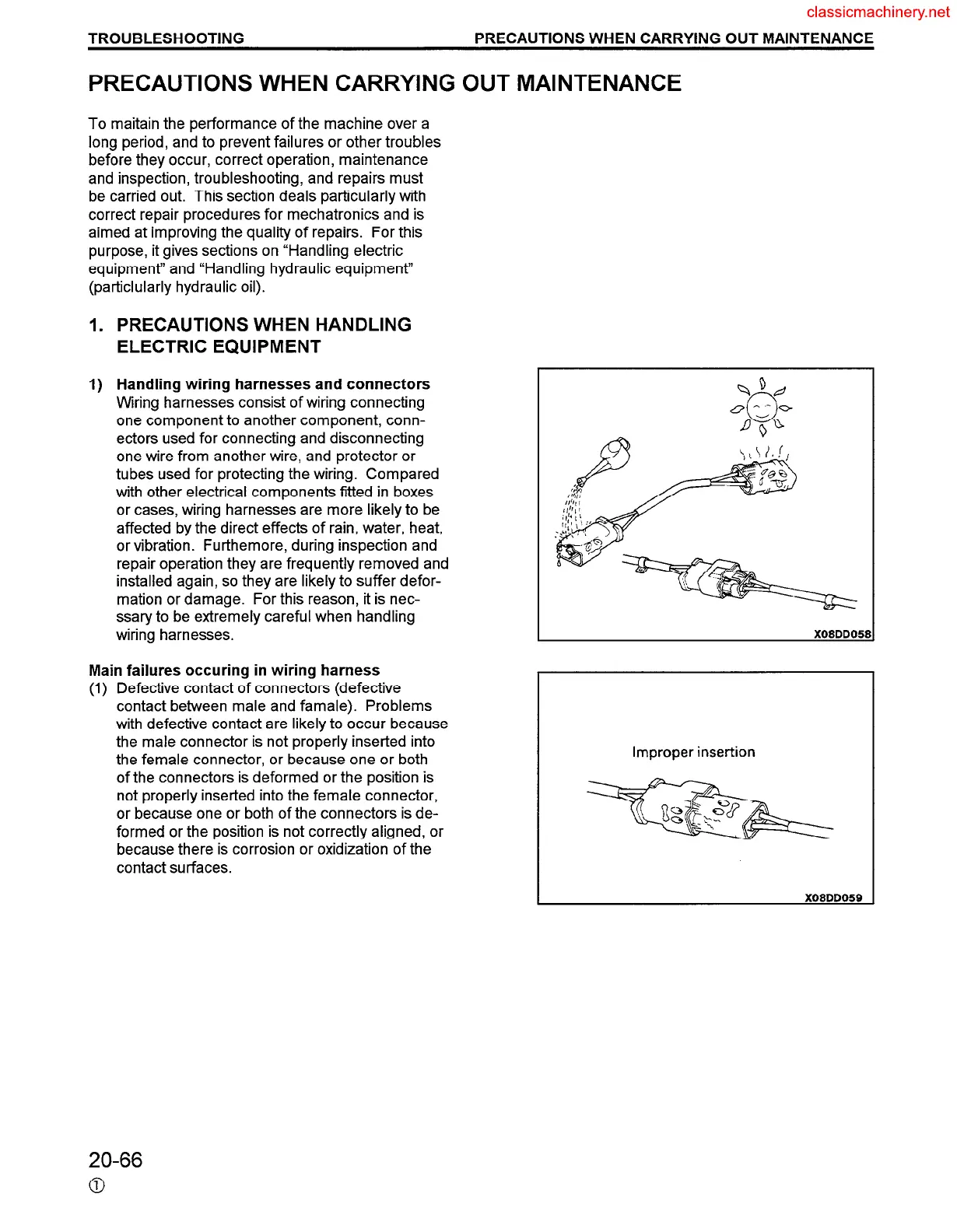

Main failures occuring in wiring harness

(1) Defective contact of connectors (defective

contact between male and famale). Problems

with defective contact are likely to occur because

the male connector is not properly inserted into

the female connector, or because one or both

of the connectors is deformed or the position is

not properly inserted into the female connector,

or because one or both of the connectors is de-

formed or the position is not correctly aligned, or

because there is corrosion or oxidization of the

contact surfaces.

Improper insertion

=3X$&$&

20-66

a

Loading...

Loading...