DISASSEMBLY AND ASSEMBLY SWING CIRCLE

INSTALLATION OF SWING

CIRCLE ASSEMBLY

0

Carry out installation in the reverse order to

removal.

m/

1 st pass:

2nd pass:

Thread of swing circle mounting bolt:

Thread tightener (LT-2)

Swing circle mounting bolt: PC200-6,

PC2OOLC-6, PC21 OLC-6, PC22OLC-6

Tighten to 191.3 f 19.6 Nm (19.5 f 2

kgm)

1)

l

2)

i)

ii)

iii)

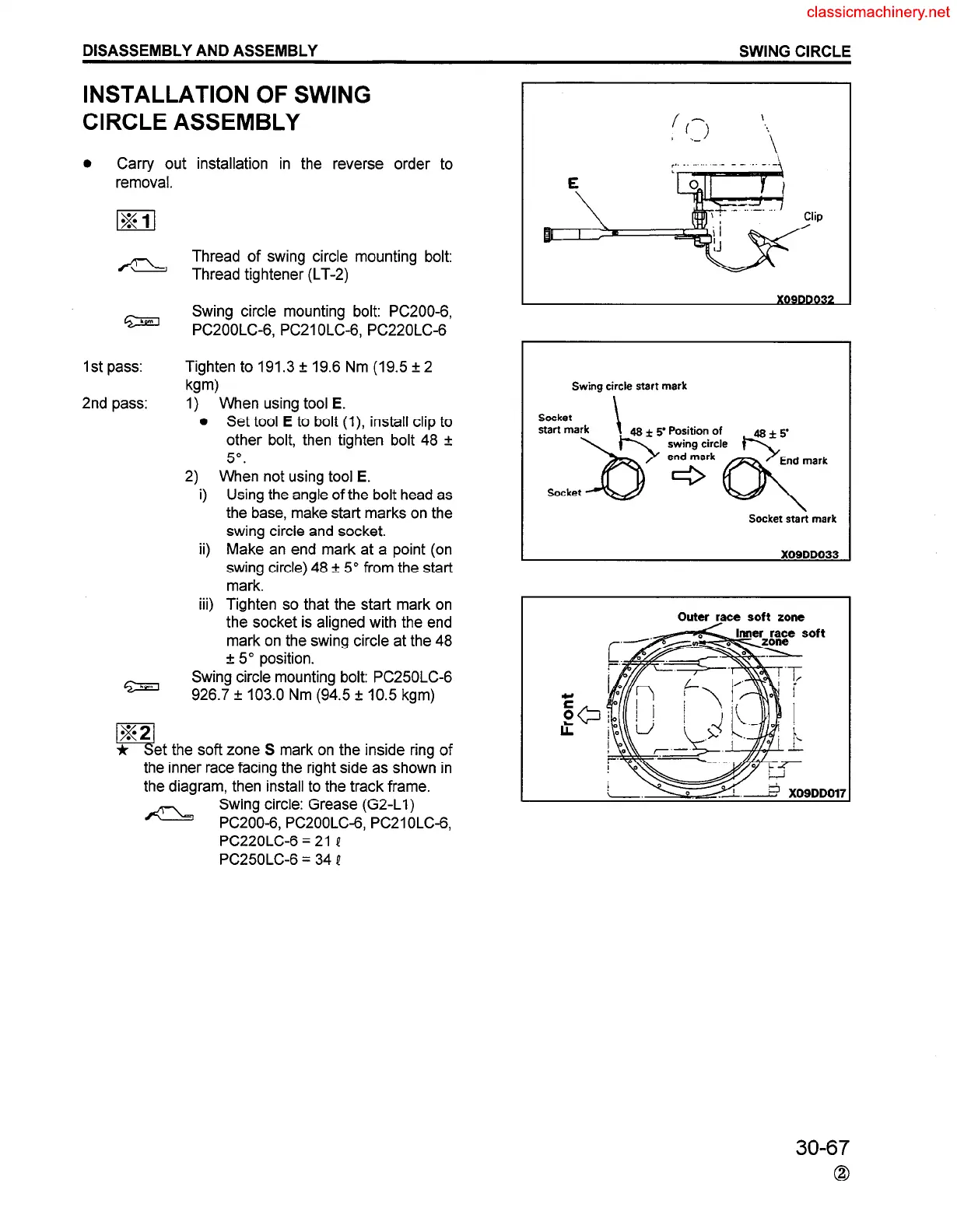

When using tool E.

Set tool E to bolt (I), install clip to

other bolt, then tighten bolt 48 f

5”.

When not using tool E.

Using the angle of the bolt head as

the base, make start marks on the

swing circle and socket.

Make an end mark at a point (on

swing circle) 48 + 5” from the start

mark.

Tighten so that the start mark on

the socket is aligned with the end

mark on the swing circle at the 48

f 5” position.

Swing circle mounting bolt: PC250LC-6

926.7 f 103.0 Nm (94.5 + 10.5 kgm)

G!

22

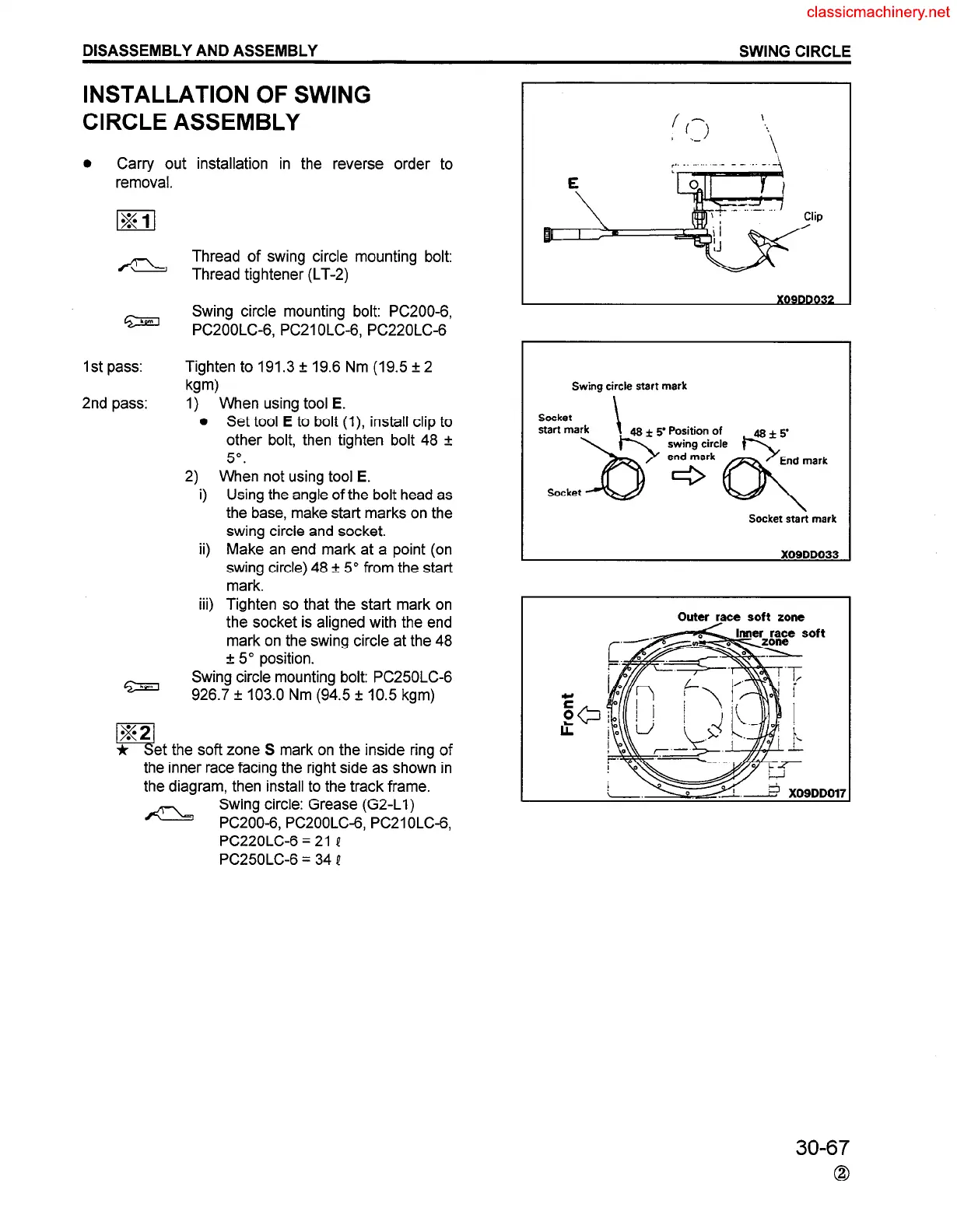

et the soft zone S mark on the inside ring of

the inner race facing the right side as shown in

the diagram, then install to the track frame.

a

Swing circle: Grease (G2-Ll)

PC200-6, PC2OOLC-6, PC21 OLC-6,

PC22OLC-6 = 21 Q

PC25OLC-6 = 34 P

lip

Swing circle start mark

Socket

start mark

socket&;zz2z$eerk

Socket start mark

Outer raoe soft zone

30-67

0

Loading...

Loading...