31/CARBURETOR

Cbeckinllhe

tloat

needle

valve

700057-10

Cbeckinlladjustinlthe

tloat

level

Condition

The float needle valve

has

been

removed.

- Check the float needle valve and the valve seat for deposits.

>

If

deposits

are

present:

- Clean the valve seat.

Clean

or change the float needle valve.

I Carburetor cleaner

(

~

p.

226)

- Check the float needle valve for wear and check the sealing areas for notches.

>

If

the sealing area is damaged or worn:

- Change the float needle valve.

Condition

The carburetor and float chamber

have

been

removed.

-

Tilt

the carburetor to one side, preventing the pin

of

the float from falling out.

183

-

Tilt

the carburetor until the float rests against the float needle valve but the float

needle valve is not pushed together.

>

If

the edge of the float

is

not parallel to the sealing

area

of the float housing in

this position:

- Adjust the float level by bending float lever

Cb8ckinll!!djustinlth8

Ihrottl8

slide

openinl

•

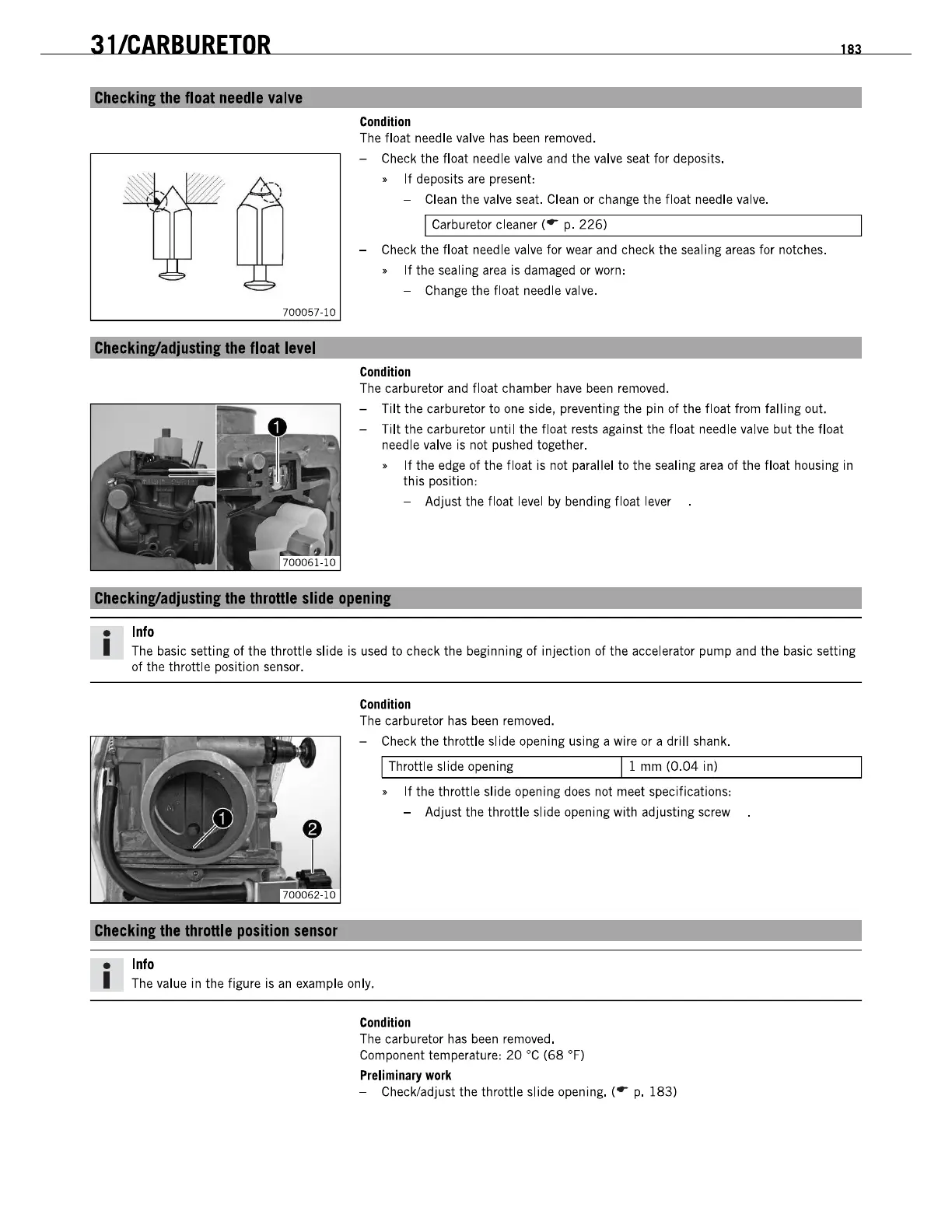

Info

I The basic setting

of

the throttle slide is

used

to check the beginning of injection of the accelerator pump and the basic setting

of the throttle position sensor.

Cbeckinllhe

throttle

osition

sensor

•

Info

Condition

The carburetor

has

been

removed.

Check the throttle slide opening using a wire or a drill shank.

I Throttle slide opening

11

mm

(0.04

in)

>

If

the throttle slide opening does not meet specifications:

- Adjust the throttle slide opening with adjusting screw

I The value in the figure

is

an

example only.

Condition

The carburetor

has

been

removed.

Component temperature:

20°C

(68

OF)

Preliminary

work

- Check/adjust the throttle slide opening.

(

~

p.

183)

Loading...

Loading...