A

5-4

Maintenance

Replacing Hose

Connector or

Plug

O-Rings

4130552

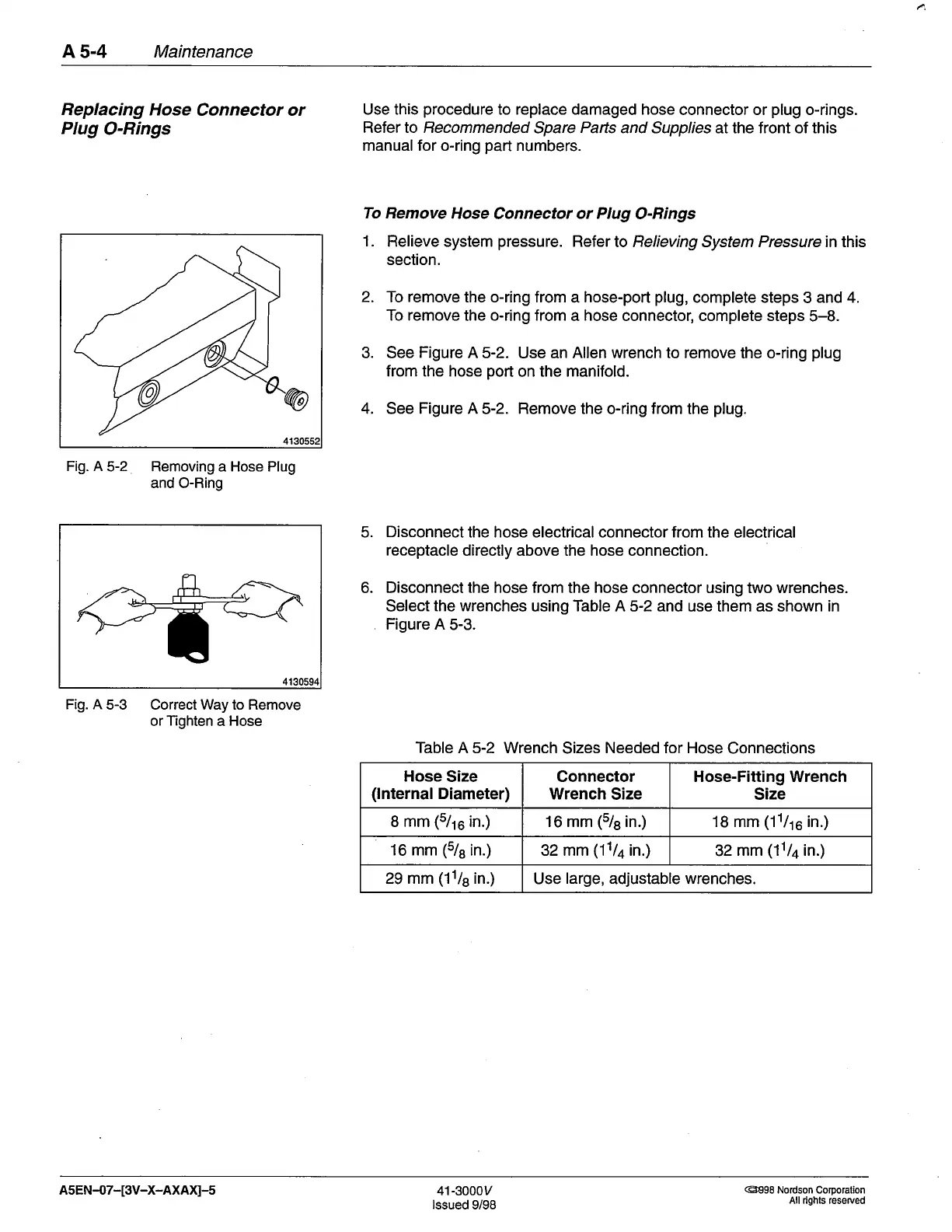

Fig. A

5-2 Removing a Hose Plug

and O-Ring

4130s94

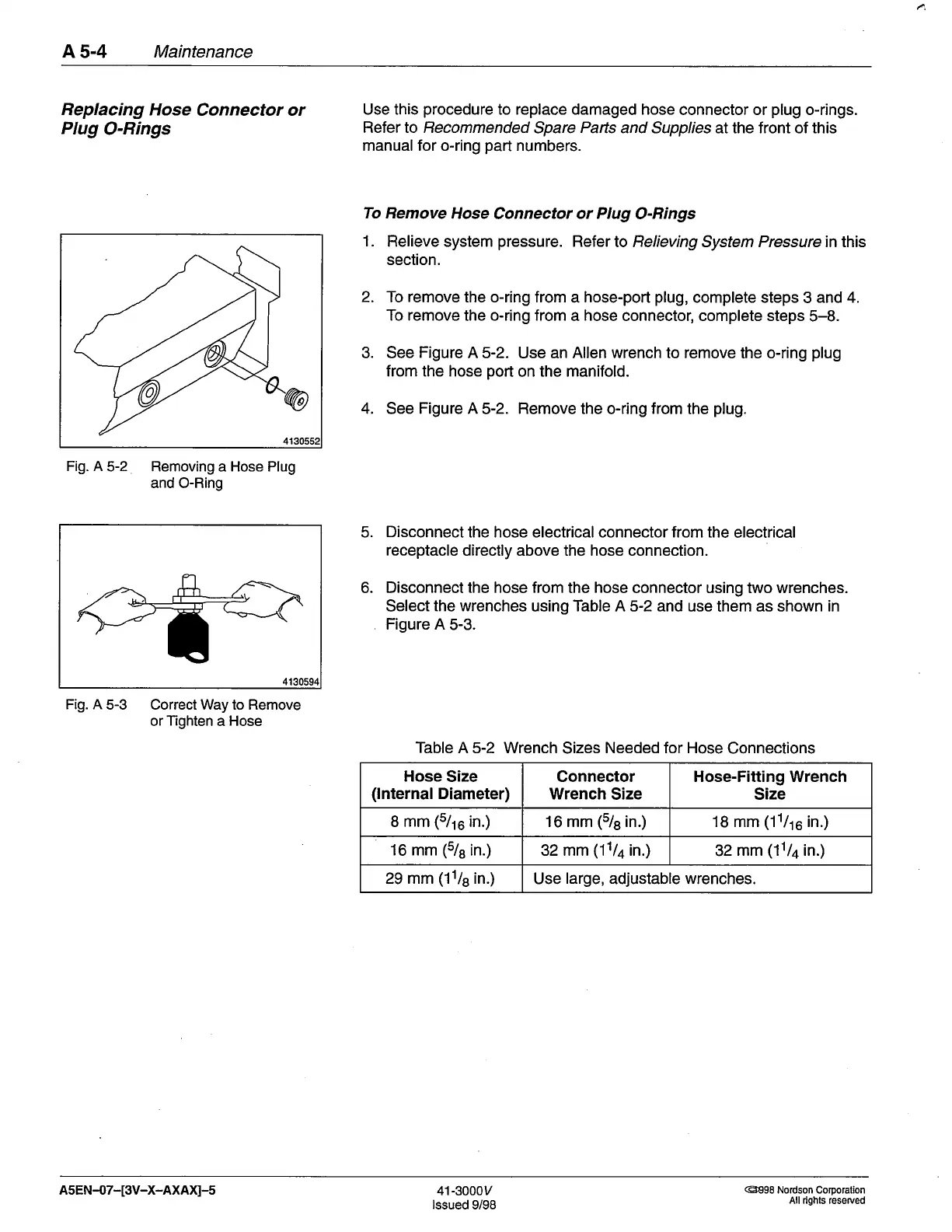

Fig. A

5-3 Correct Way to Remove

or

Tighten

a Hose

Use this

procedure

to replace damaged hose

connector or

plug

o-rings.

Refer to Recommended

Spare

Parts

and Supplies at the front of this

manual for o-ring

part

numbers.

To Remove

Hose

Connector

or Plug

O-Rings

1.

Relieve system

pressure.

Refer

to Relieving System Pressure in this

section.

2. To remove the o-ring from

a

hose-port

plug,

complete steps

3

and 4

To remove

the

o-ring from

a hose connector, complete steps

5-8.

3. See

Figure

A5-2.

Use an

Allen wrench to remove

the o-ring

plug

from the hose

port

on the manifold.

4.

See

Figure A5-2.

Bemove the o-ring from the

plug.

5.

Disconnect

the hose electrical connector from the

electrical

receptacle

directly above the hose connection.

6.

Disconnect the hose from

the

hose

connector using two wrenches.

Select

the wrenches

using Table A 5-2 and use

them

as shown in

Figure A

5-3.

Table

A 5-2 Wrench

Sizes

Needed for Hose

Connections

Hose

Size

(lnternal

Diameter)

Connector

Wrench

Size

Hose-Fitting Wrench

Size

8 mm

(s/16

in.) 16 mm

(s/e

in.) 18 mm

(11/16

in.)

16 mm

(s/a

in.) 32 mm

(11/+

in.)

32

mm

(11/4

in.)

29 mm

(11/8

in.)

Use

large,

adjustable wrenches.

AsEN-07-[3V-X-AXAX]-s

41-3000v

lssued 9/98

@898

Nordson Corporation

All rights reserved

Loading...

Loading...