RTD-Style Hot Melt Hose

23

5920023

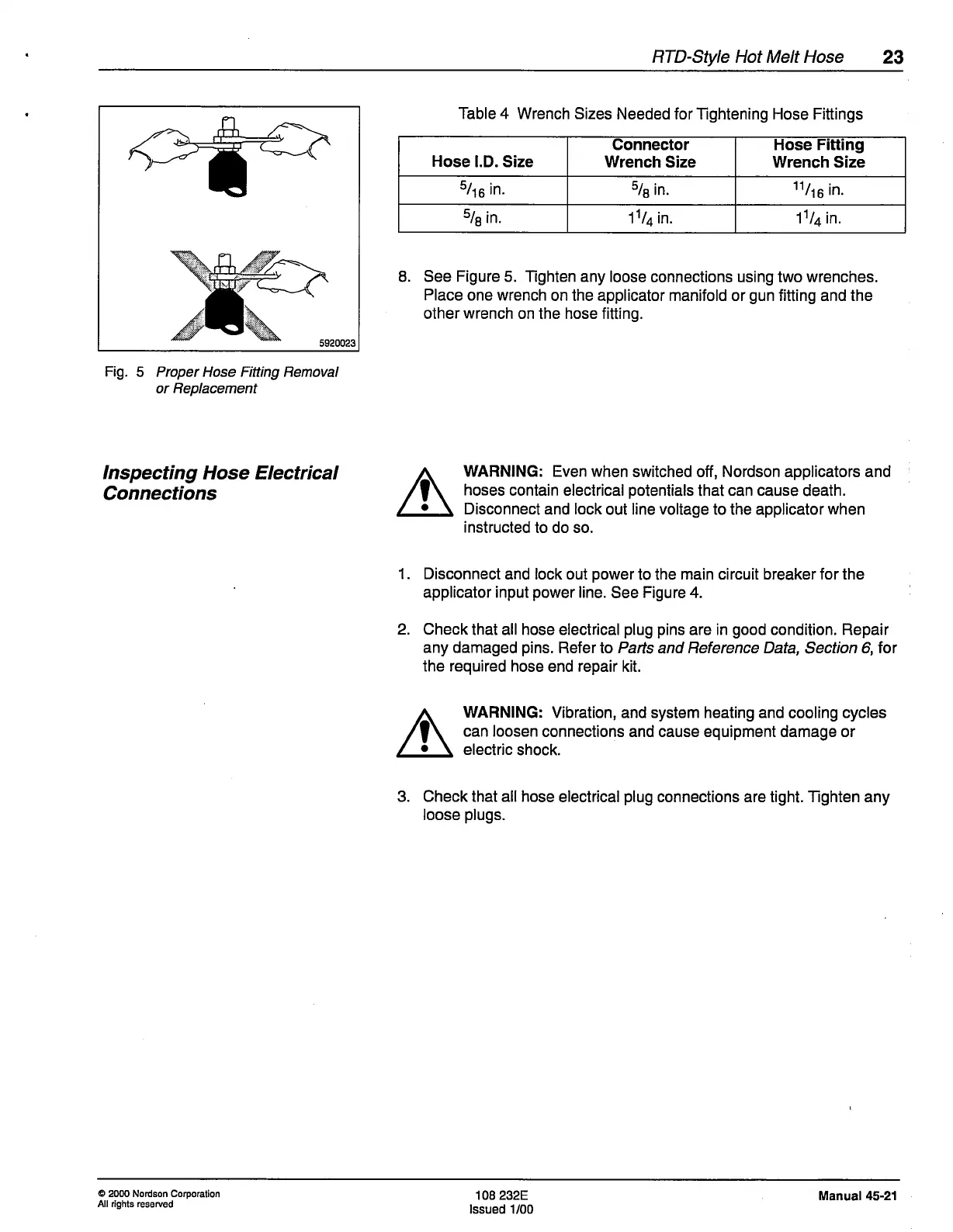

Fig.

5 Proper Hose Fitting Removal

or Replacement

lnspecting Hose Electrical

Connections

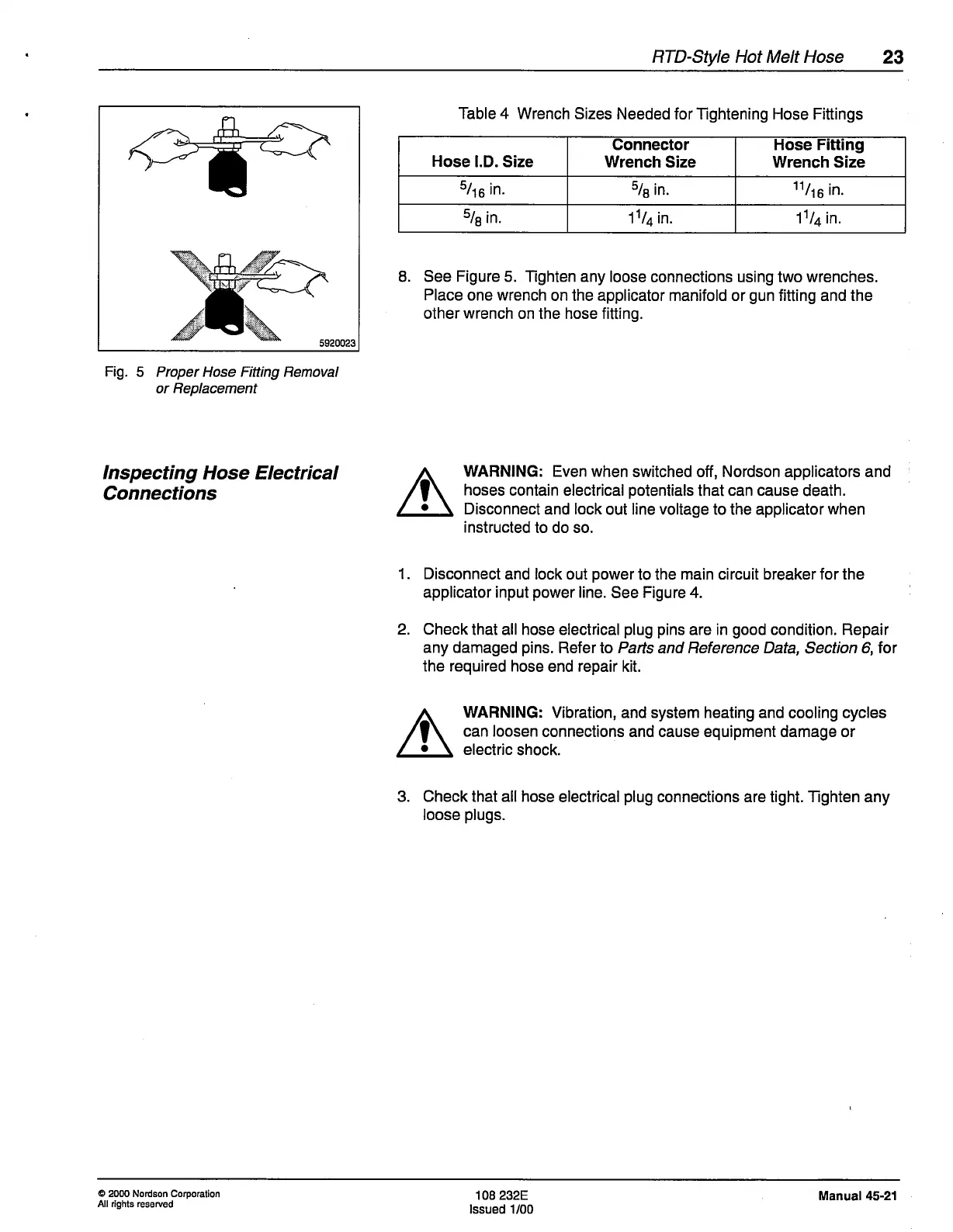

Table 4 Wrench

Sizes Needed for Tightening Hose

Fittings

8. See Figure 5. Tighten any

loose connections using two wrenches.

Place

one wrench

on the applicator manifold or

gun

fitting and the

other

wrench

on

the

hose fitting.

WARNING: Even when

switched off, Nordson applicators and

hoses

contain electrical

potentials

that

can cause

death.

Disconnect

and

lock

out line voltage to the applicator when

instructed

to do so.

1. Disconnect

and lock out

power

to the

main circuit breaker for the

applicator input

power

line.

See

Figure

4.

2. Check

that all hose electrical

plug pins

are in

good

condition. Repair

any damaged

pins.

Refer to Parts

and

Reference Data,

Section

6, tor

the required hose

end repair kit.

WARNING:

Vibration, and system heating and

cooling

cycles

can loosen

connections and cause equipment damage or

electric

shock.

3. Check that all hose

electrical

plug

connections are tight. Tighten any

loose

plugs.

Hose l.D. Size

Gonnector

Wrench Size

Hose Fatung

Wrench Size

5/16

in.

s/s

in

11/16

in

s/s

in.

11lain 11/ain

O

2U)0 Nordson Corporation

All rights reserued

108232E

lssued 1/00

Manual 45-21

Loading...

Loading...