A

5-14

Maintenance

1

2

4904034

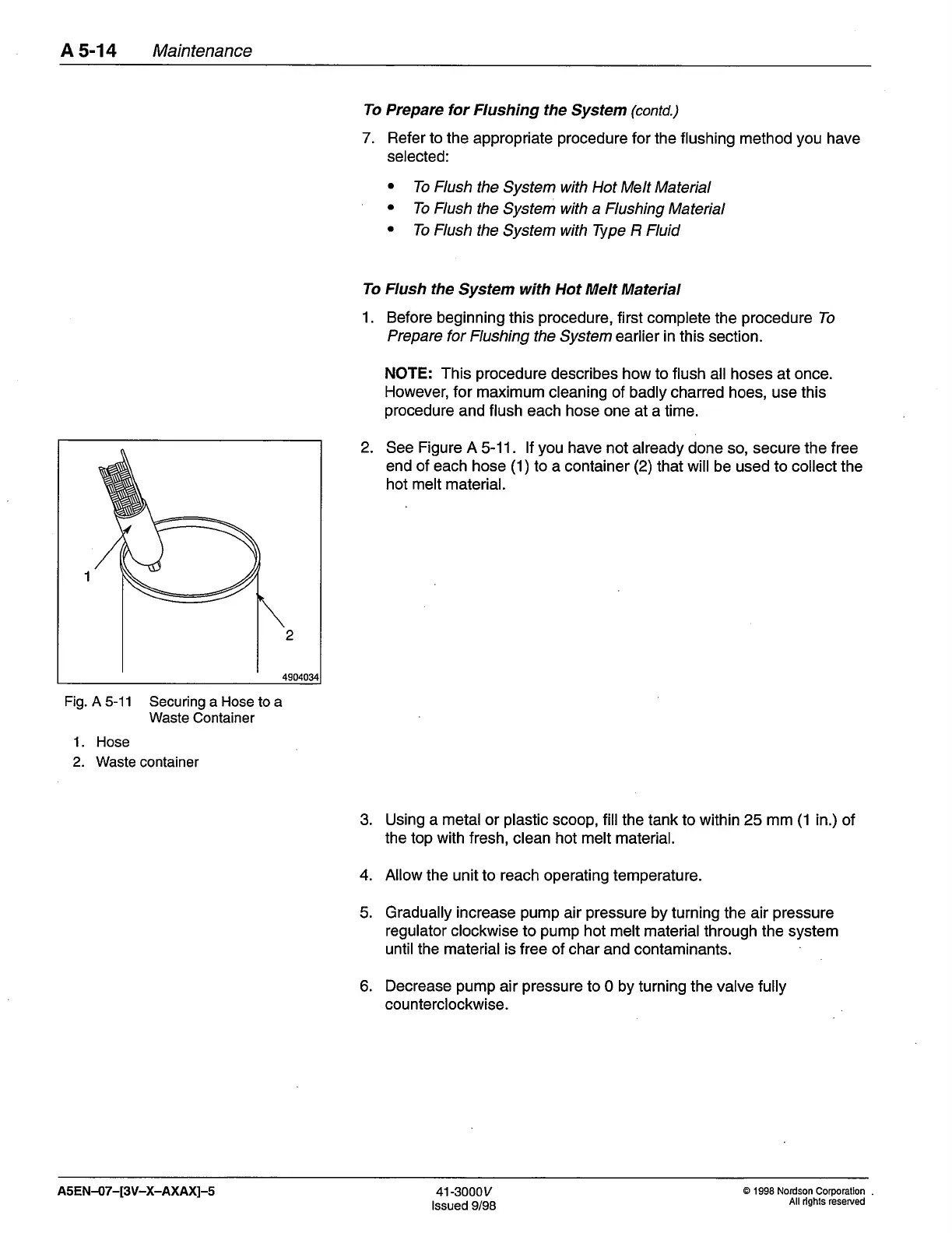

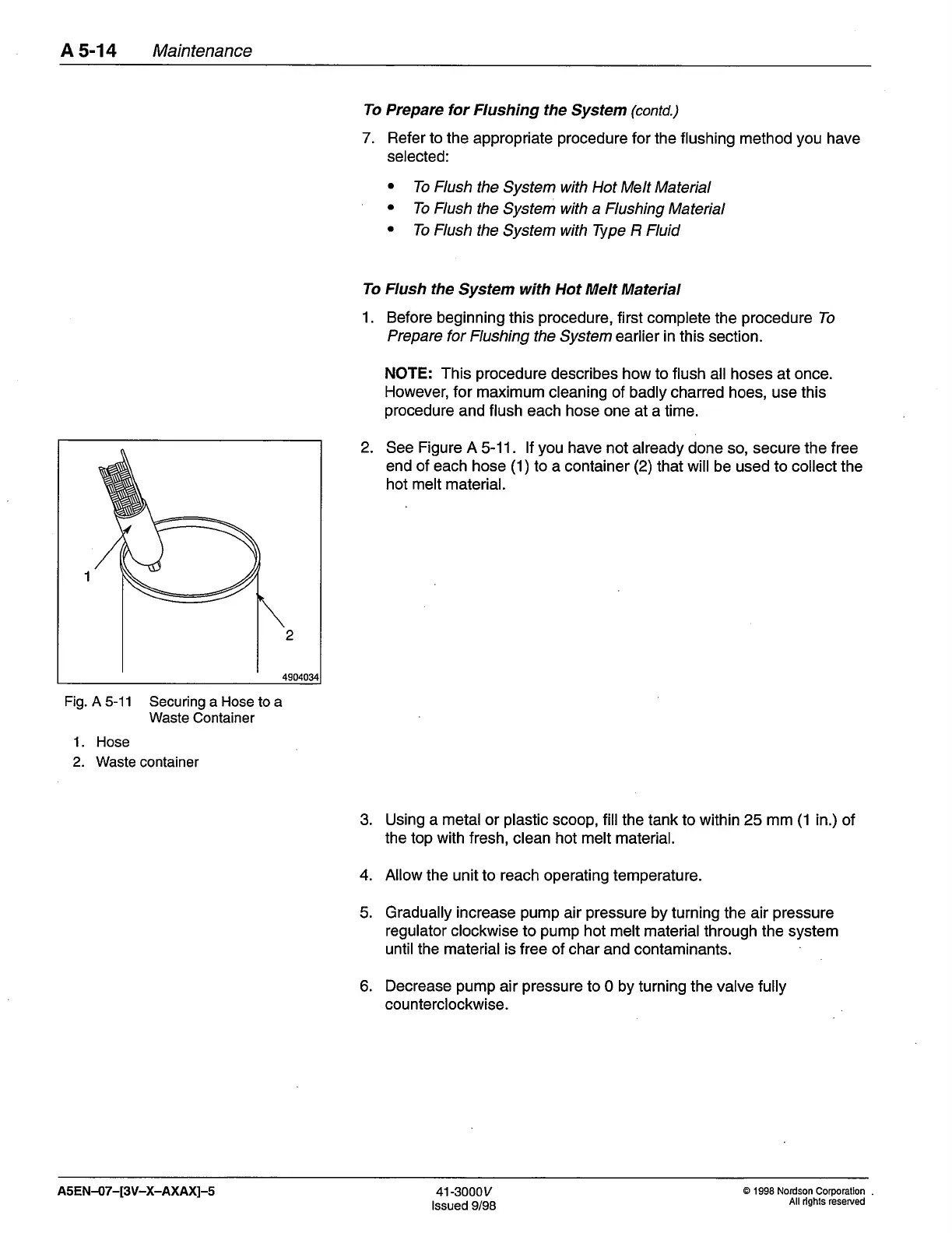

Fig. A 5-11 Securing

a

Hose

to a

Waste Container

1. Hose

2. Waste

container

To Prepare for Flushing the

System

(contd.)

7. Refer to the

appropriate

procedure

for the flushing

method

you

have

selected:

.

To Flush

the System with Hot Melt Material

.

To Flush

the

System

with a Ftushing Ailaterial

.

To Flush

the

System

with Type R Fluid

To Flush the

System

with Hot Melt Material

1. Before beginning

this

procedure,

first complete

the

procedure

Io

Prepare

tor Flushing the

System earlier

in

this section.

NOTE: This

procedure

describes how to flush

all hoses at

once

However, for maximum

cleaning of badly charred hoes, use this

procedure

and flush each hose one

at a time.

2.

See Figure A

5-11.

lf

you

have

not already done

so,

secure the free

end of each hose

(1)

to a container

(2)

that will be

used

to collect the

hot melt material.

3.

Using

a metal or

plastic

scoop,

fill

the tank to within 25 mm

(1

in.) of

the top with fresh,

clean hot melt material.

4.

Allow the unit to reach operating temperature.

5. Gradually

increase

pump

air

pressure

by turning

the air

pressure

regulator clockwise

to

pump

hot

melt materialthrough the system

until the material is free

of

char

and contaminants.

6.

Decrease

pump

air

pressure

to 0 by turning the valve fully

counterclockwise.

AsEN-07-[3V-X-AXAX]-5

41-3000y

lssued 9/98

@

1998 Nordson

Corporation

All rights resewed

Loading...

Loading...