Cleaning Procedures

J012/J013/J014 3-60 SM

3.10 CLEANING PROCEDURES

The responsibility of the service technician is limited because this machine is adjusted for

optimum performance at the factory before it is shipped.

Return the printer to the repair center or replace the machine if a serious problem occurs.

There are no parts that require scheduled maintenance or replacement. However, the

service technician should do the procedures described in this section when a service call is

requested.

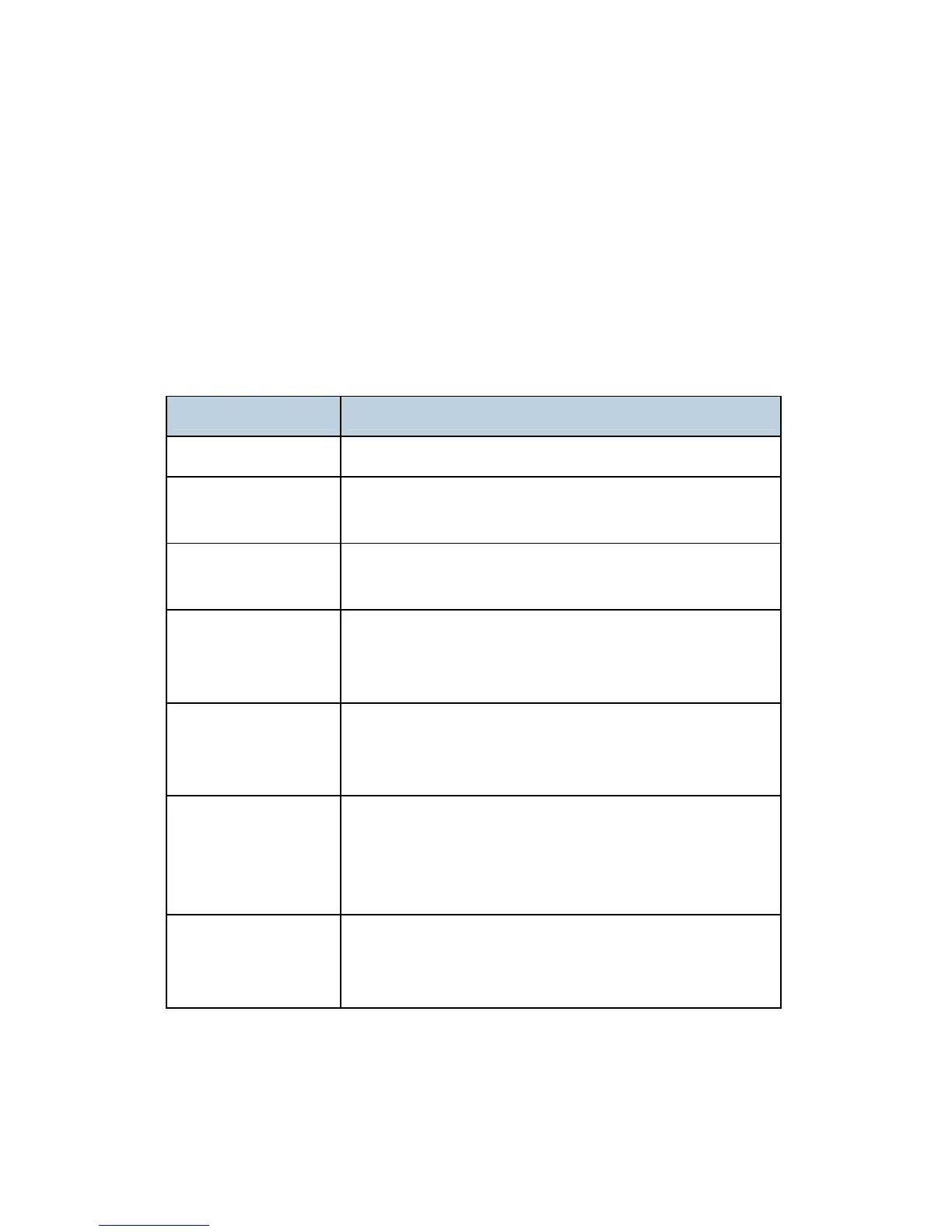

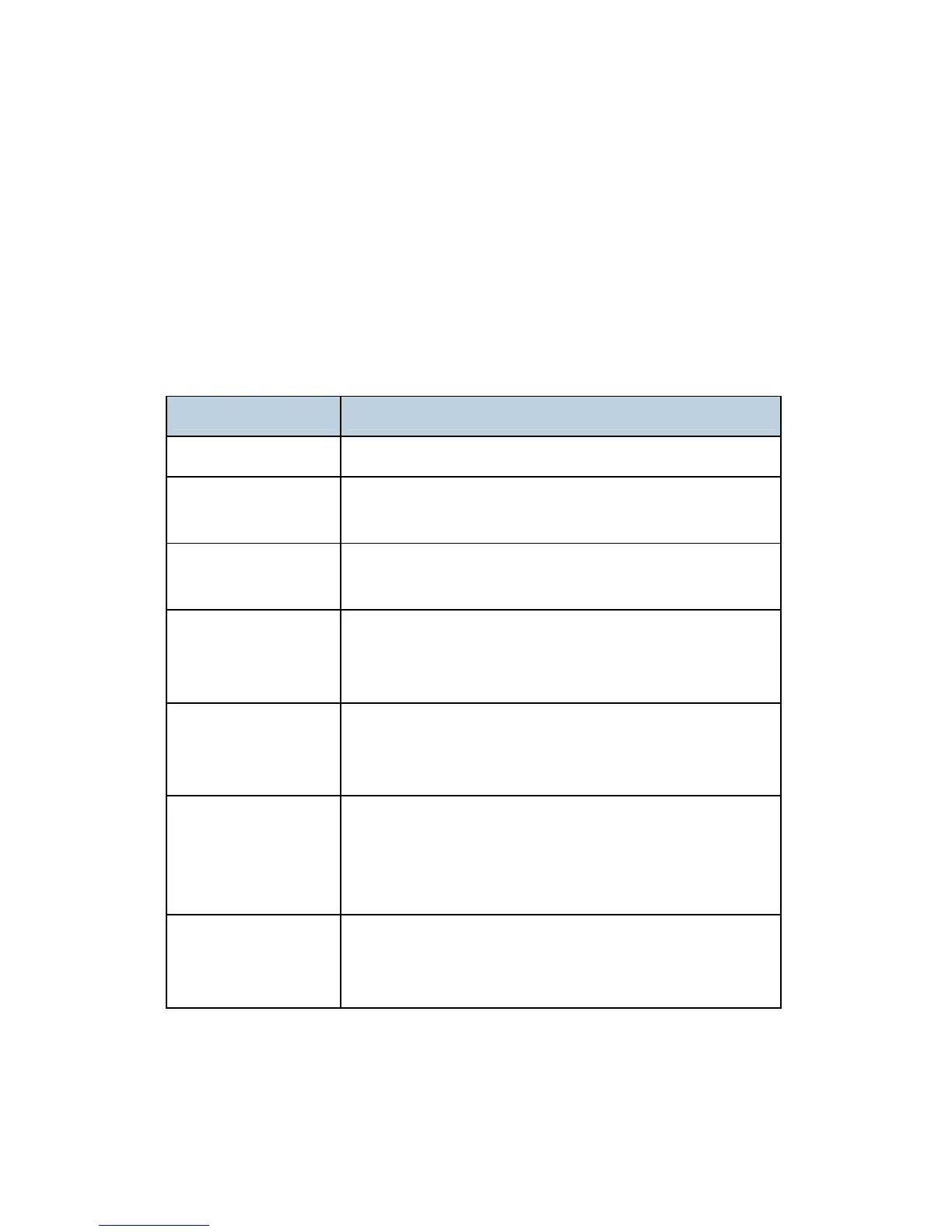

Description At Service Call (or When Necessary)

External Covers Damp cloth.

Feed Roller Damp cloth. Release the feed clutch lock. Rotate the roller

freely as you clean it.

Friction Pad Damp cloth. This is the cork friction pad on the front edge of the

standard paper cassette (Tray 1).

Printer Operation, Print

Quality

Print a Nozzle Check Pattern and check the results. Clean the

print heads if necessary. For more, see "Image Adjustment" "3.

Replacement and Adjustment.”

Ink Collector Tank A message on the printer operation panel prompts you to

replace the ink collector unit after it has become full.

For more, see "3. Replacement and Adjustment.”

Flushing Unit Gate Dry cloth. Always remove the ink that has hardened around the

flushing gate slots when you replace the ink collector tank. To

scrape away hardened ink, you may need to use a small

screwdriver

Maintenance unit Wet cloth (use water). Always use a tightly wrapped dry cloth to

remove the ink that has hardened around the suction cap and

wiper blade when you replace the ink collector tank.

Loading...

Loading...