Loading Flat Material

Load the flat material on the cutting machine. If flat material is used, it must be at least 100 mm

(3.94 in.) longer (70 mm [2.76 in.] when the cutting area is extended in the length direction) than the

vertical size of the cutting data. This is the length required for the pinch rollers to feed out the mate-

rial to the front and rear.

CAUTION

Never load media that weighs over 24 kg (52.9 lb.) (54-inch model: 20 kg

[44.1 lb.]).

The machine may fail to withstand the weight and tip over or cause the media to fall.

Procedure

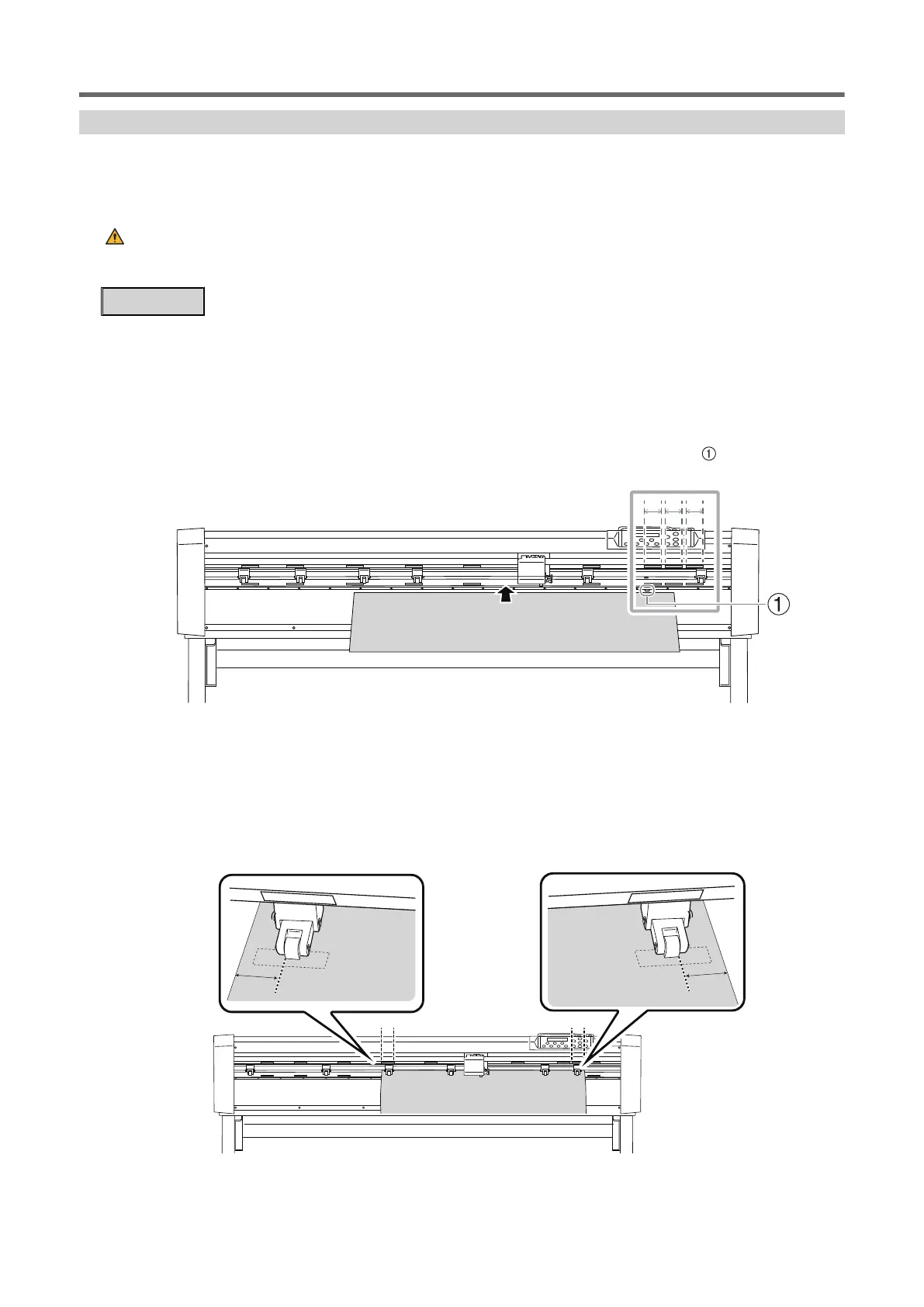

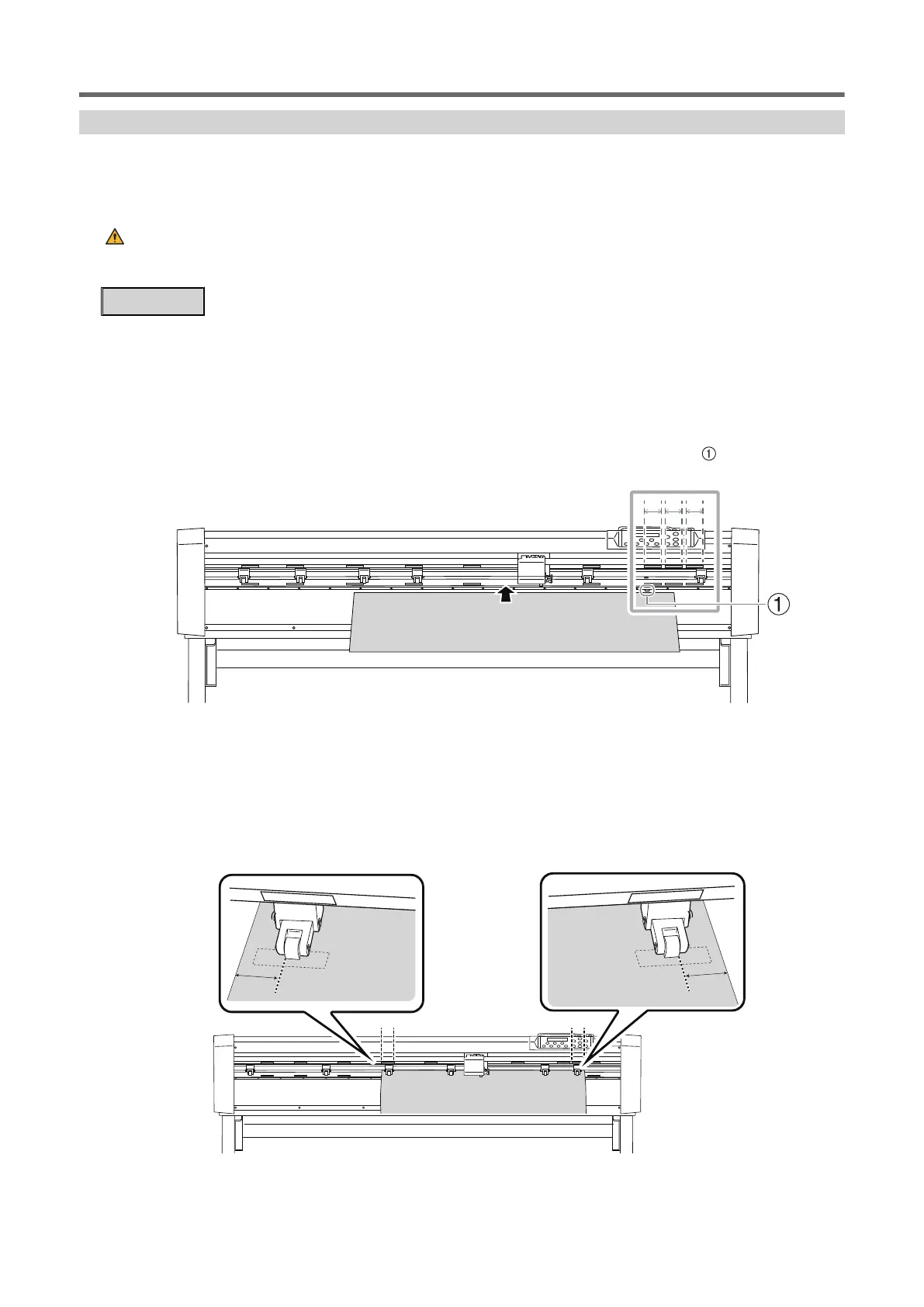

1. Check that the lever is raised.

If the lever is lowered, raise the lever.

2. Pass the material in a straight manner between the pinch rollers and grit rollers using the gradations

of the rulers (in two locations: one on the top and one on the bottom) as a guideline.

Ensure that the right edge of the material (looking from the front of the machine) is positioned

so that it is within the range of the grit patterns and covers the paper sensor (

).

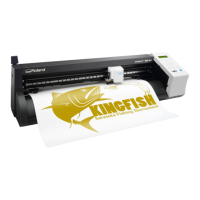

3. Move the pinch rollers and place them on both edges of the flat material.

Check that the pinch rollers are positioned within the range of the grit patterns. If the pinch

rollers are not placed within the range of the grit patterns, the material cannot be fed proper-

ly.

Position the pinch rollers on the edges so that each one is 0.5 to 25 mm (0.02 to 0.98 in.) (if

the roll material used is more than 4 m [157.49 in.] long, then more than 25 mm [0.99 in.])

inside of the respective left or right edge of the material.

Loading the Material

Basic Settings and Operations 29

Loading...

Loading...