To use this machine for printing and cutting material with cutting data printed, you must perfectly

align the printed graphics and the cutting positions. The crop marks digitally generated around the

graphics can be automatically detected for accurate alignment. In this manual, this feature is called

AAS.

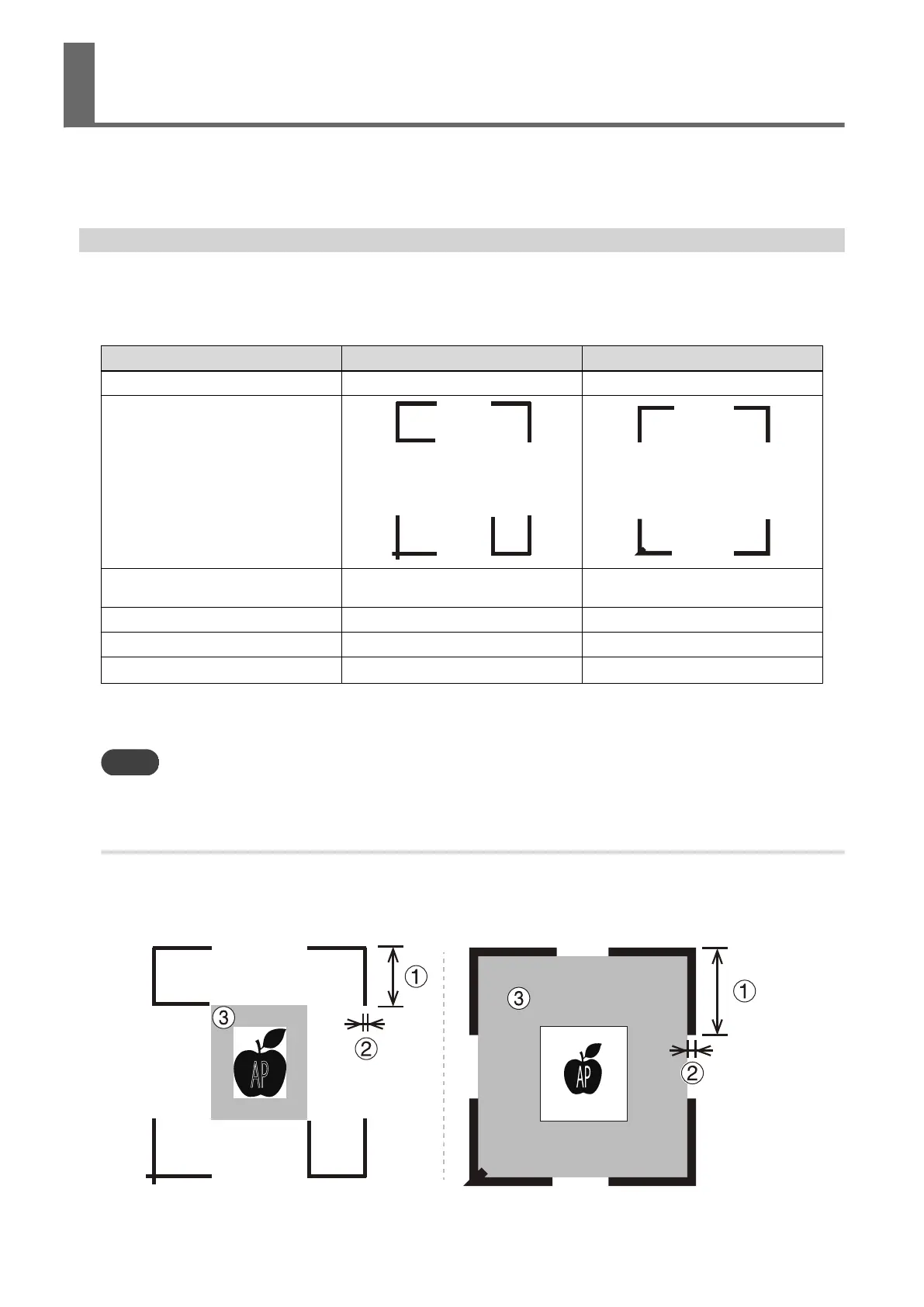

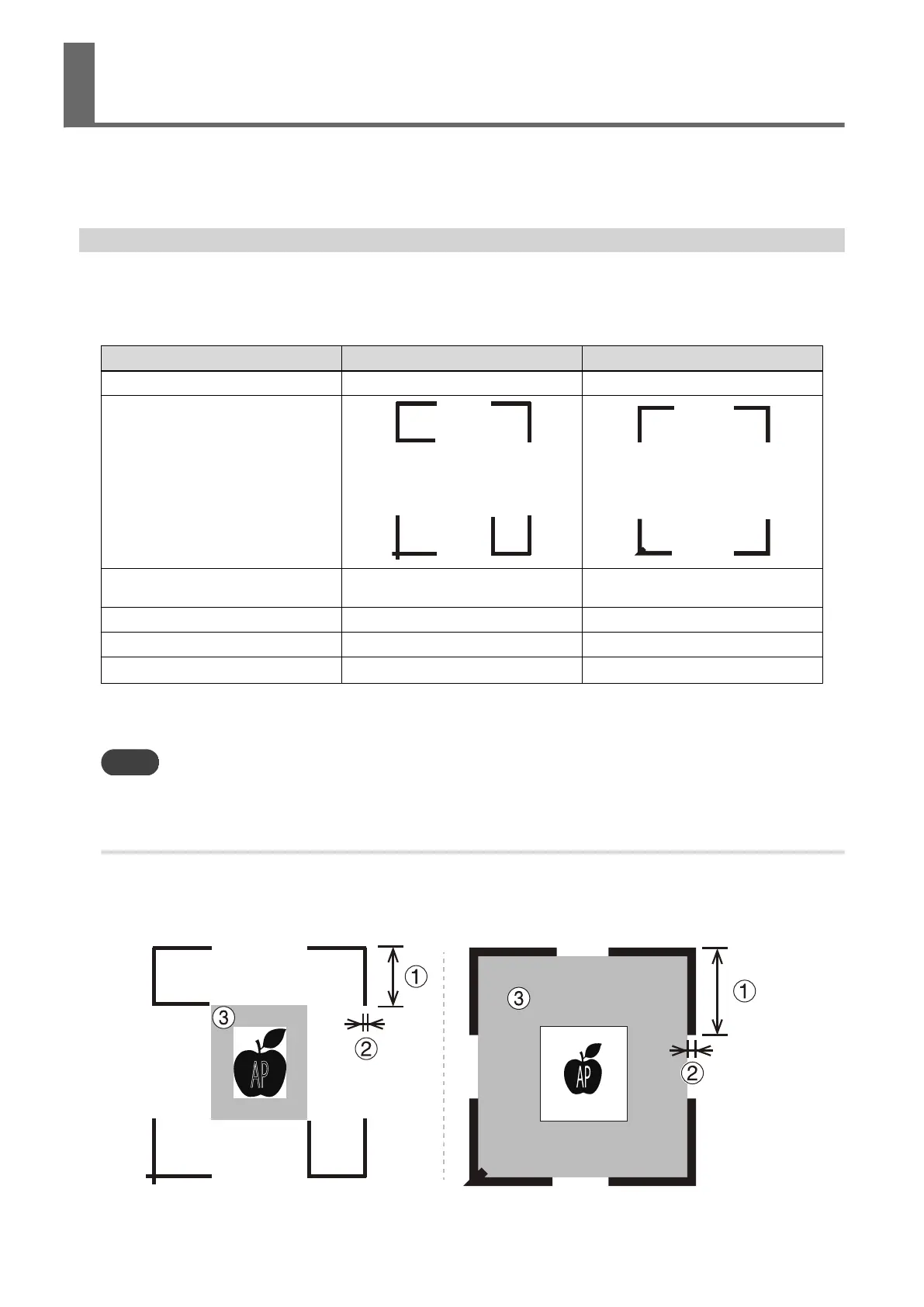

Crop Mark Types

Cutting job functions, the shape of four corners, and the job output source differ depending on crop

marks generated by the AAS plug-in or GreatCut-R plug-in. Select the method to generate crop marks

based on factors such as the cutting data and time required for cutting.

AAS plug-in GreatCut-R plug-in (GreatCut-R)

Cutting data output Printer driver GreatCut-R

Crop mark shape

Automatic Detection of Material Feed Di-

rection

✓ x

Multiple cutting ✓ x

Section Cutting ✓ x

Crop mark generation target

Page

*1

/Object

Object

*1 Crop marks are generated in the four corners of a cutting data page (inside the space with sufficient length for material

feeding).

MEMO

Crop marks are created on the selected object or page (work page for cutting data). When creating crop marks on an

object, you can set up three different types of crop marks suitable for the cutting data.

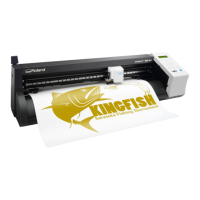

Four-point

This type of crop mark is the basic crop marks created in the four corners of the selected object. The

settings for four-point crop marks are applied to all crop marks. These crop marks are used to set up

crop marks for each page instead of in an object.

Automatic Aligning System (AAS)

58 Basic Printing and Cutting

Loading...

Loading...