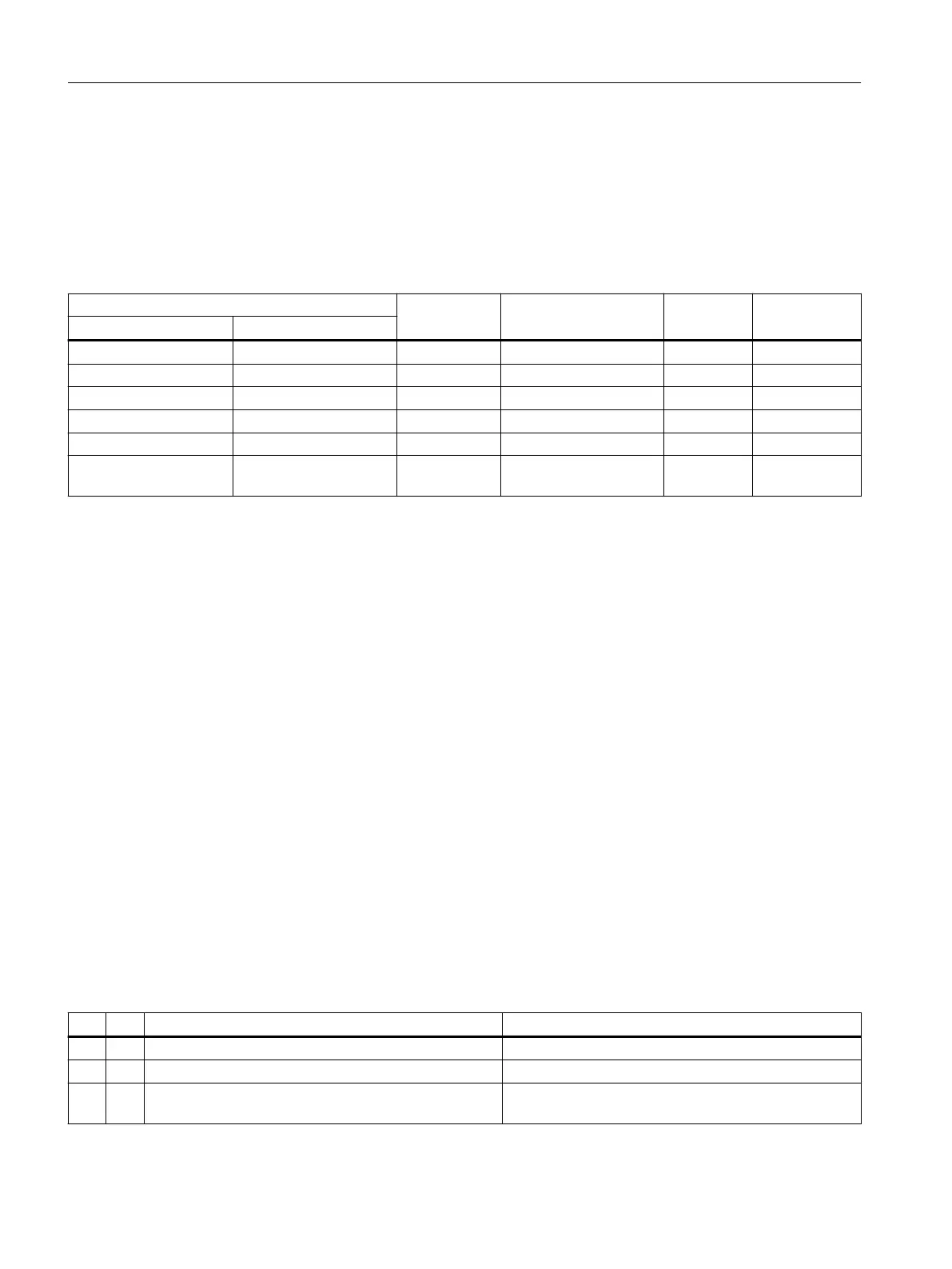

9.3.2 Useful data through PROFIBUS

Cyclic useful data

The positioner can exchange a combination of the following cyclic useful data through

PROFIBUS:

Name Abbreviation Direction from the posi‐

tioner's point of view

Length in

byte

Comprising:

German English

Setpoint Setpoint SP Input 5 Value/Status

Readback Readback RB Output 5 Value/Status

Position discrete Position discrete POS_D Output 2 Value/Status

Checkback Checkback CB Output 3 Value

Remote Cascade Input Remote Cascade Input RCAS_IN Input 5 Value/Status

Remote Cascade Out‐

put

Remote Cascade Out‐

put

RCAS_OUT Output 5 Value/Status

Setpoint

The setpoint is divided into a floating point value (4 bytes) and the corresponding status (1 byte,

see further below).

Actual value

The actual value indicates the valve position. The actual value is divided into a floating point

value (4 bytes) and the corresponding status (1 byte).

Position discrete

The discrete valve position is displayed as a value (1 byte) having the following meaning:

0 = not initialized

1 = valve closed

2 = valve open

3 = valve in the intermediate position: Even this value has a status (1 byte).

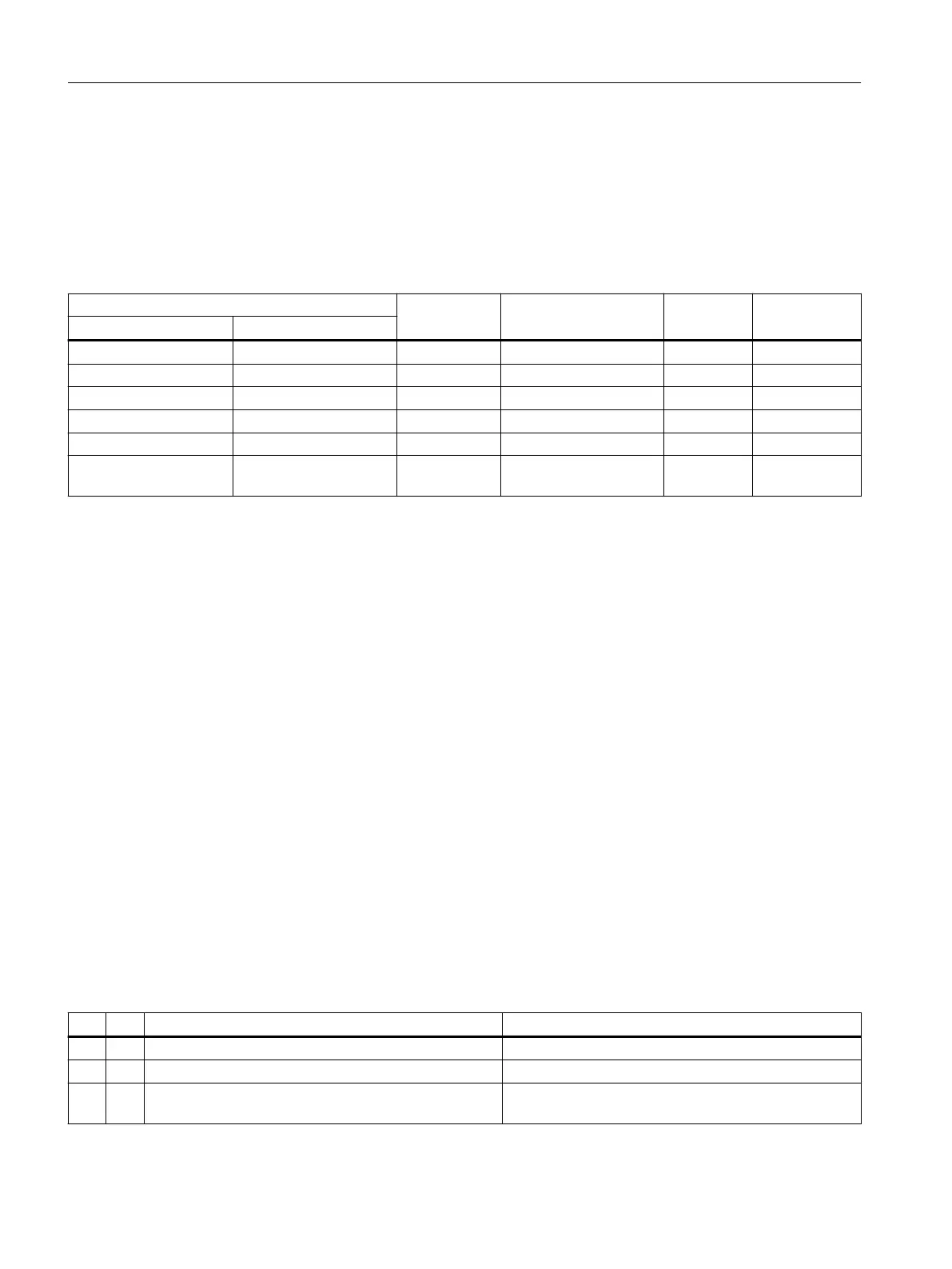

Checkback

The checkback is displayed in 3 bytes in a bit-coded format:

Bit Meaning of "1" Remarks

0 0 Device in the fail safe position The position is determined by the "49.FSTY" parameter.

1 Request for on-site operation Reports that a button has been pressed.

2 The device is operated on-site. The device is parameterized on-site, e.g. using the

"1.YFCT" parameter or is not initialized.

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

212 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...