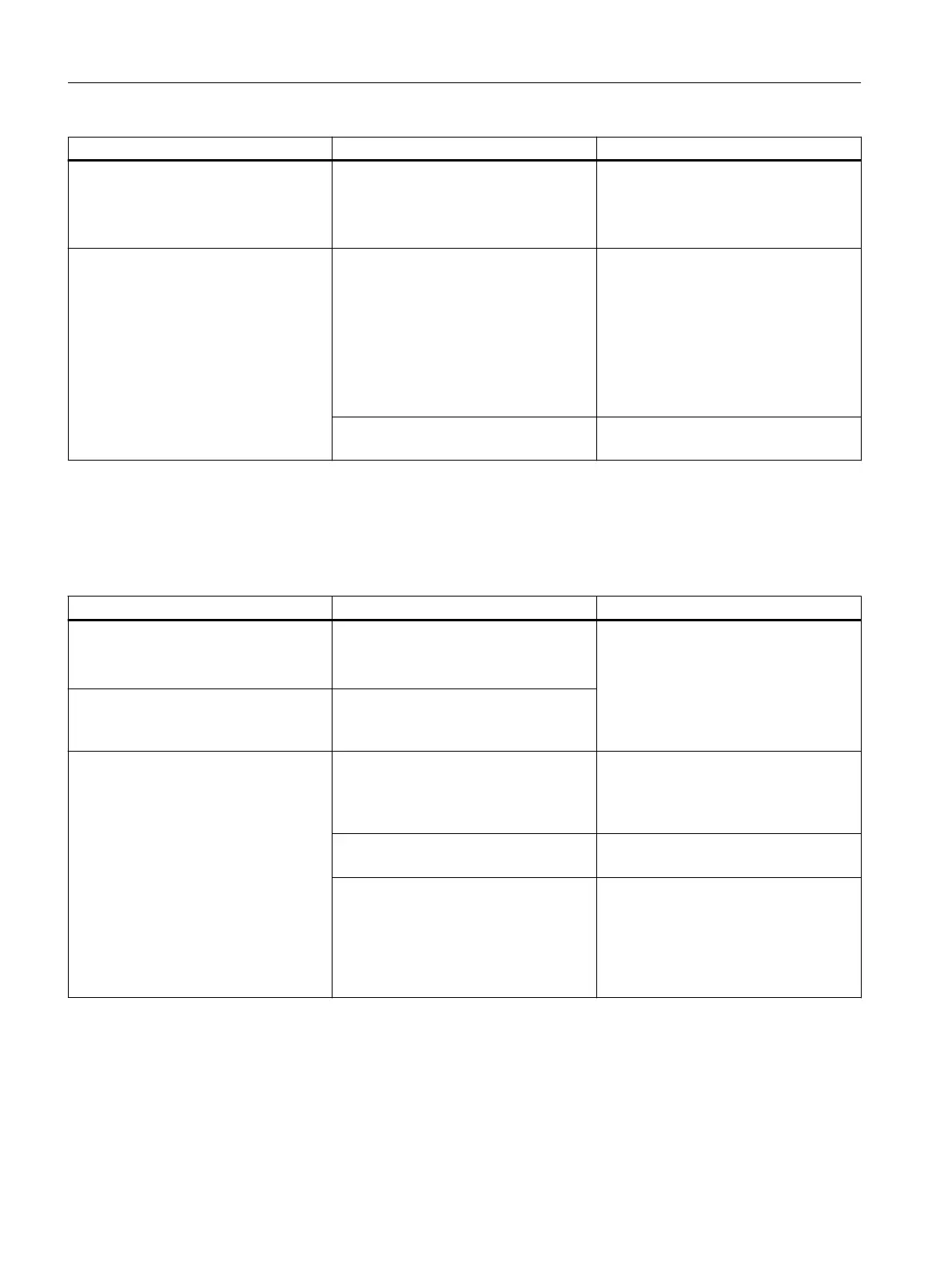

Fault profile (symptoms) Possible cause(s) Corrective measures

● Positioner remains in "RUN 3". ● Actuator travel time is too high. ● Open the restrictor completely

and/or set the pressure PZ (1) to the

highest permissible value.

● Use a booster if required.

● Positioner remains "RUN 5", does

not go up to "FINISH" (waiting time

> 5 min).

● "Gap" (play) in the positioner -

actuator - control valve system

● Part-turn actuator: check for the

firmness of the grub screw of the

coupling wheel

● Linear actuator: check for the

firmness of the lever on the

positioning shaft.

● Correct any other play between the

actuator and the control valve.

● Diagnostic value "9.TUP" or

"10.TDOWN" < 1.5 s

● Set the traversing velocity to > 1.5 s

using the internal restrictor.

Fault table 1

12.4.3 Remedial measures table 2

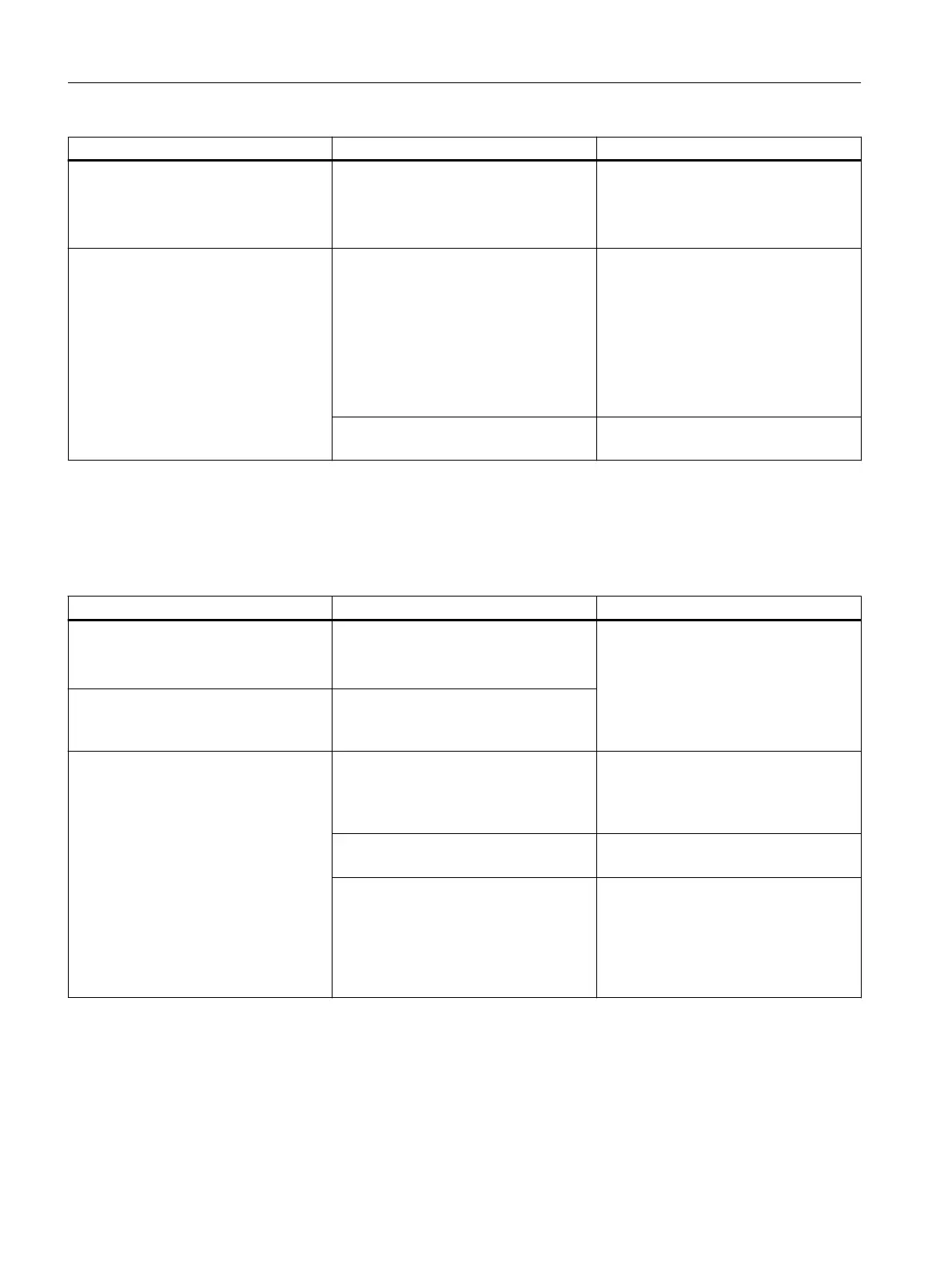

Fault profile (symptoms) Possible cause(s) Corrective measures

● "CPU testt" blinks on the display

approximately every 2 seconds.

● Piezo valve does not activate.

● Water in the pneumatic block (due to

wet compressed air)

● At an early stage, this fault can be

rectified with a subsequent

operating using dry air, if required, in

a temperature cabinet at 50°C to

70°C.

● Otherwise: Repair

● In the manual and automatic modes,

the actuator cannot be moved or can

be moved only in one direction.

● Moisture in the pneumatic block

● Piezo valve does not activate (a

gentle click sound is not audible

when the "+" or "-" buttons are

pressed in the manual mode.)

● The screw between the shrouding

cover and the pneumatic block has

not been tightened firmly or the

cover got stuck.

● Tighten the screw firmly; if required,

rectify the deadlock.

● Dirt (swarf, particles) in the

pneumatic block

● Repair or a new device; clean and/or

replace the built-in fine screens.

● Deposits on the contacts between

the electronic printed circuit board

and the pneumatic block can

develop due to abrasion owing to

continuous loads resulting from

strong vibrations.

● Clean all contact surfaces with spirit;

if required, bend the pneumatic

block contact springs.

Fault table 2

See also

Repair/Upgrading (Page 244)

Diagnostics and troubleshooting

12.4 Fault correction

SIPART PS2 with PROFIBUS PA

278 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...