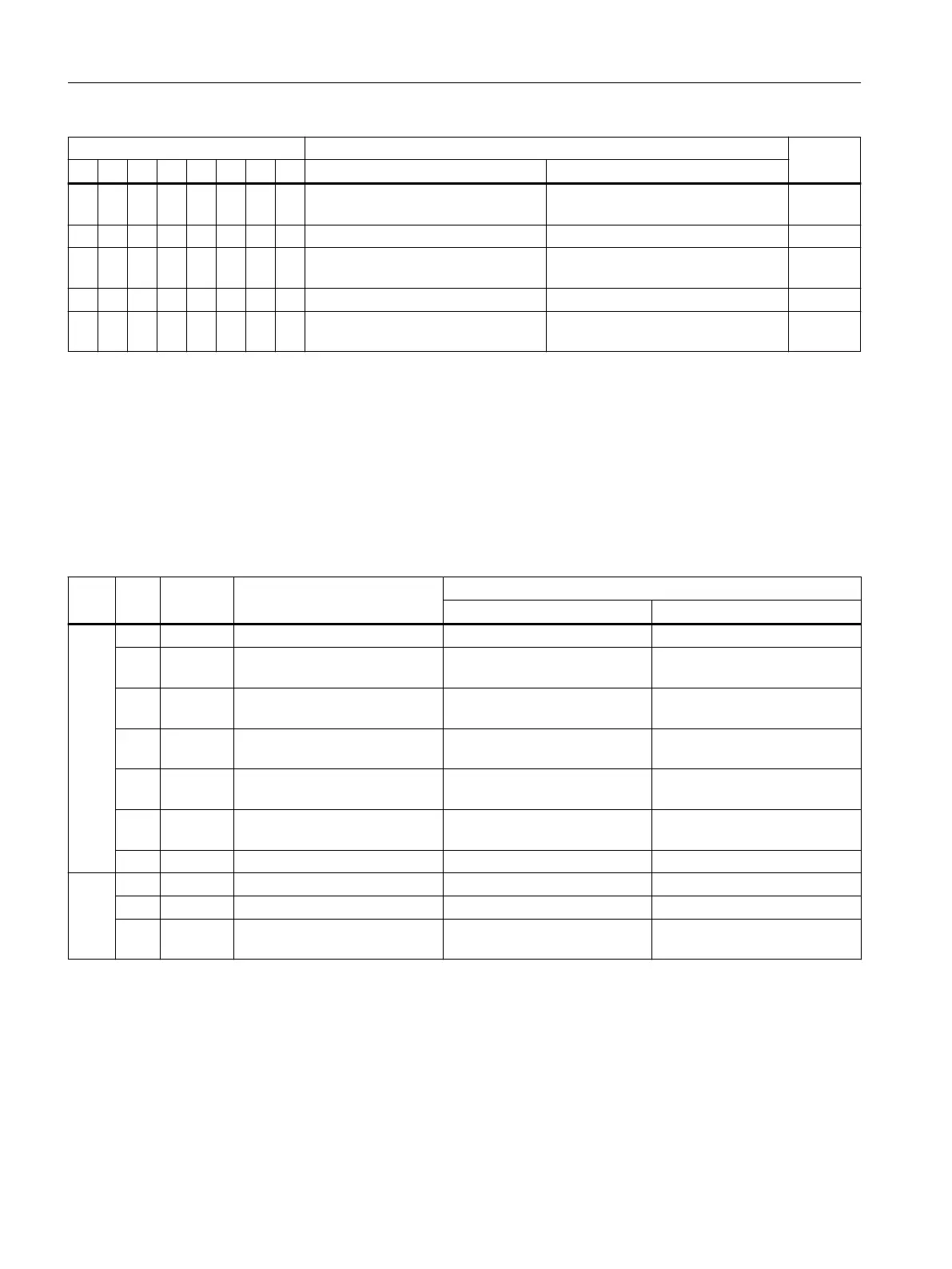

Bits Name Group

7 6 5 4 3 2 1 0 Profile German

0 1 1 1 1 0 x x Uncertain, process related, no main‐

tenance

Unsicher, Prozess-Störung, kein

Wartungsbedarf

P

1 0 0 0 0 0 x x Good, ok Gut, Ok -

1 0 1 0 0 1 x x Good, maintenance required Gut, Instandhaltungsbedarf M1,

M12, M

1 0 1 0 1 0 x x Good, maintenance demand Good, maintenance requirement M12, M

1 0 1 1 1 1 x x Good, function check Gut, Funktion überprüfen / Handbe‐

trieb

F

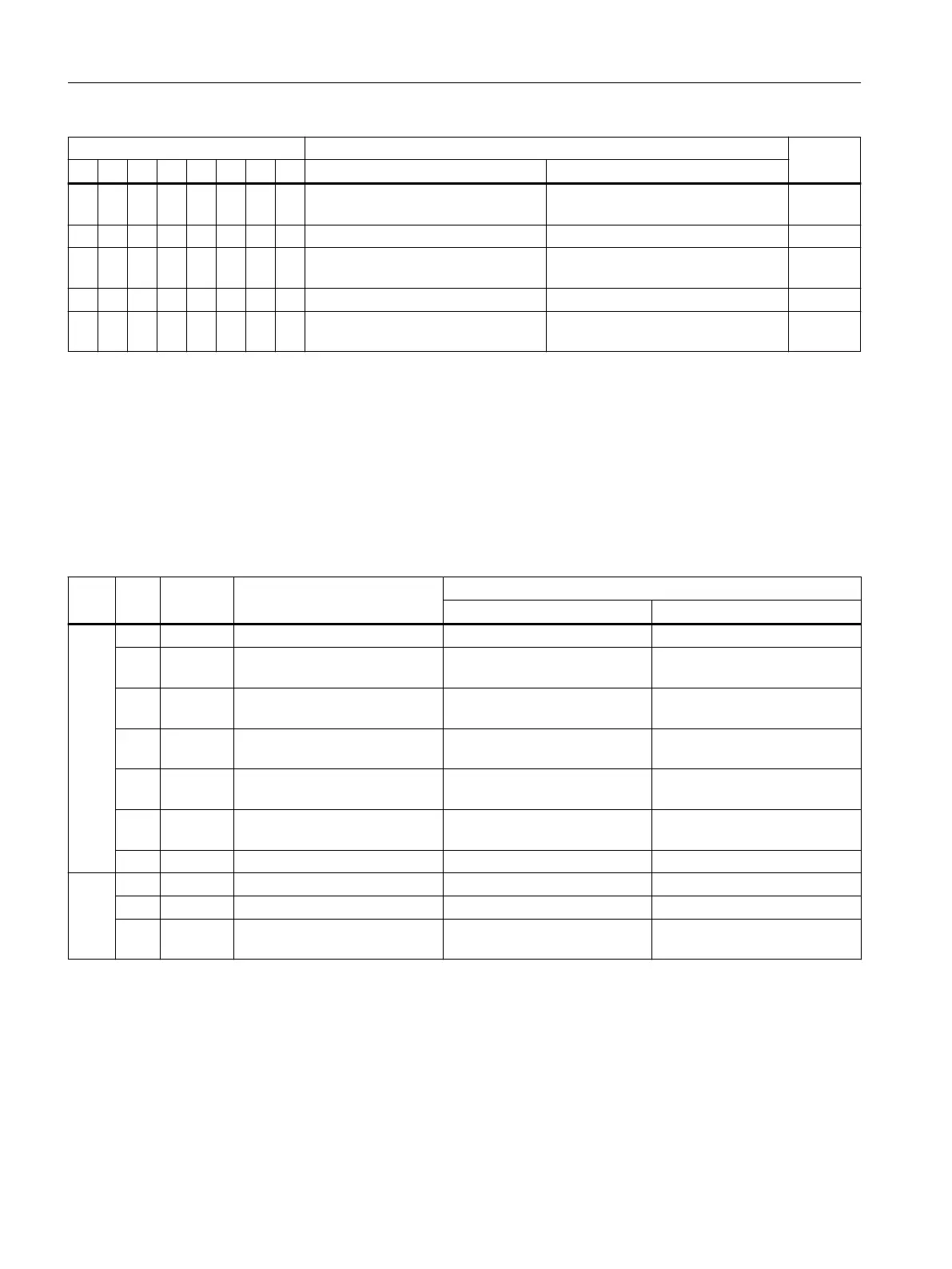

9.3.3.6 List of diagnostics events with status and diagnostics message for deactivated

condensed status

A list of diagnostics events with status and diagnostics message for deactivated condensed

status is given in the following table. DIAGNOSTICS_EXTENSION and

DIAGNOSTICS_EXTENSION_2 are physical block parameters.

DIAGNOSTICS_EXTENSION physical block parameter

Byte Bit No. Diagnostics events Hard-coded effect of a diagnostics event

Quality status code DIAGNOSTICS bit

0 0 1 Run time error of the actuator Bad, maintenance requirement DIA_SUPPLY

1 2 The device is not in the "Auto‐

matic mode"

Uncertain, simulation value None

2 3 Binary 1 is active (only mes‐

sage)

Good, maintenance required DIA_MAINTENANCE

3 4 Action triggered by binary input

1

Uncertain, simulation value None

4 5 Binary 2 is active (only mes‐

sage)

Good, maintenance required DIA_MAINTENANCE

5 6 Action triggered by binary input

2

Uncertain, simulation value None

7 ... 21 Reserved - -

2 5 22 Limit for alarm A1 exceeded Good, maintenance required DIA_MAINTENANCE

6 23 Limit for alarm A2 exceeded Good, maintenance required DIA_MAINTENANCE

7 24 Error in the device electronic

unit

Bad, device error DIA_MEM_CHKSUM

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

228 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...