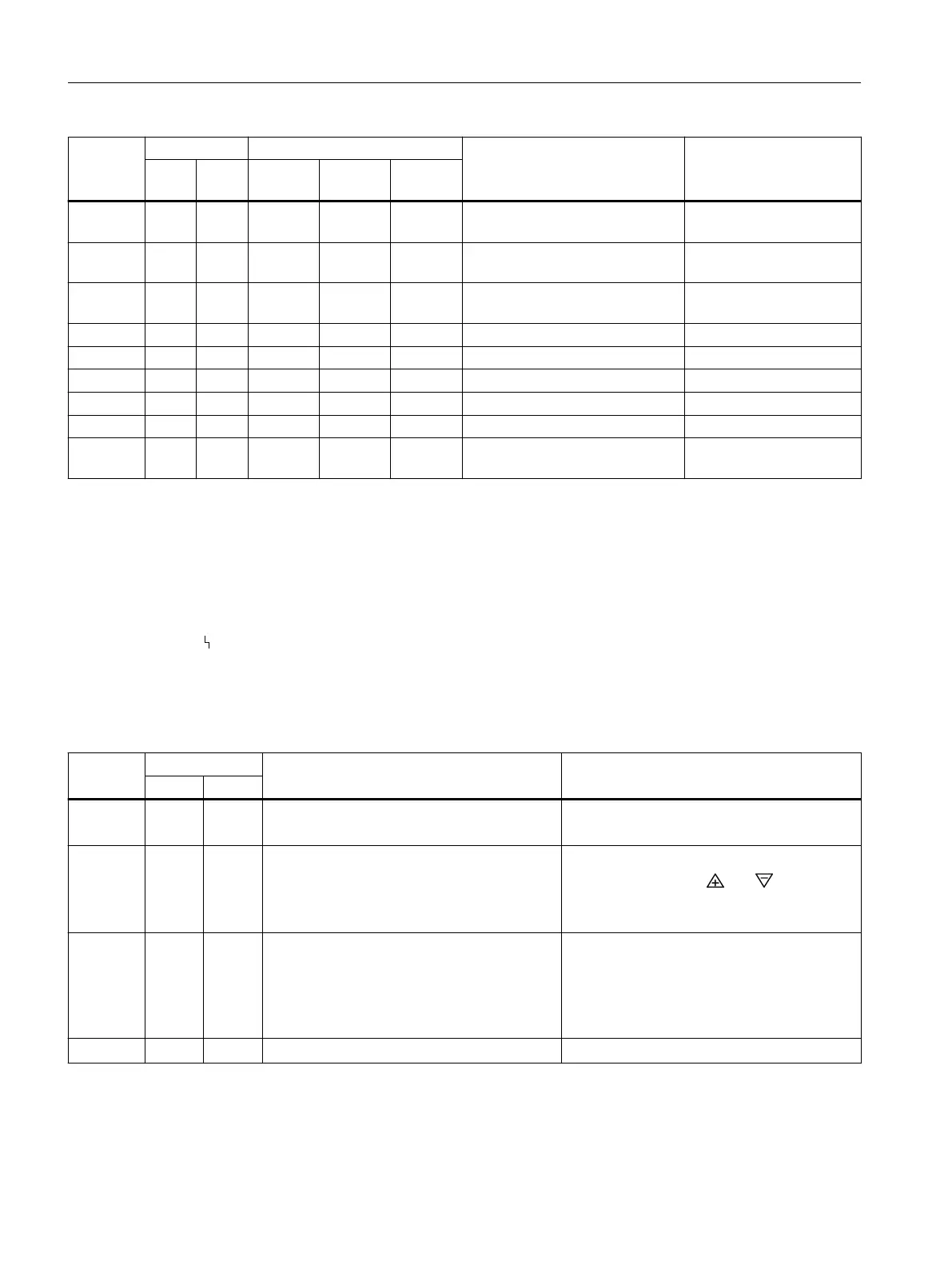

Message Line Operating mode Meaning / cause Measure

Up Down Automat‐

ic

Manual

mode

P man‐

ual mode

EX UP X X Actuator is moved to the upper

endstop by the binary input.

EXDWN X X Actuator is moved to the lower

endstop by the binary input.

EXPSt The partial stroke test was activa‐

ted, e.g. by the binary input.

InPSt Cyclic partial stroke test.

FST X X Full stroke test running.

SRT X X Step response test running.

MSRT X X Multi-step response test running.

VPT X X Valve performance test running.

LEAKR X X A leakage test started by commu‐

nication is running.

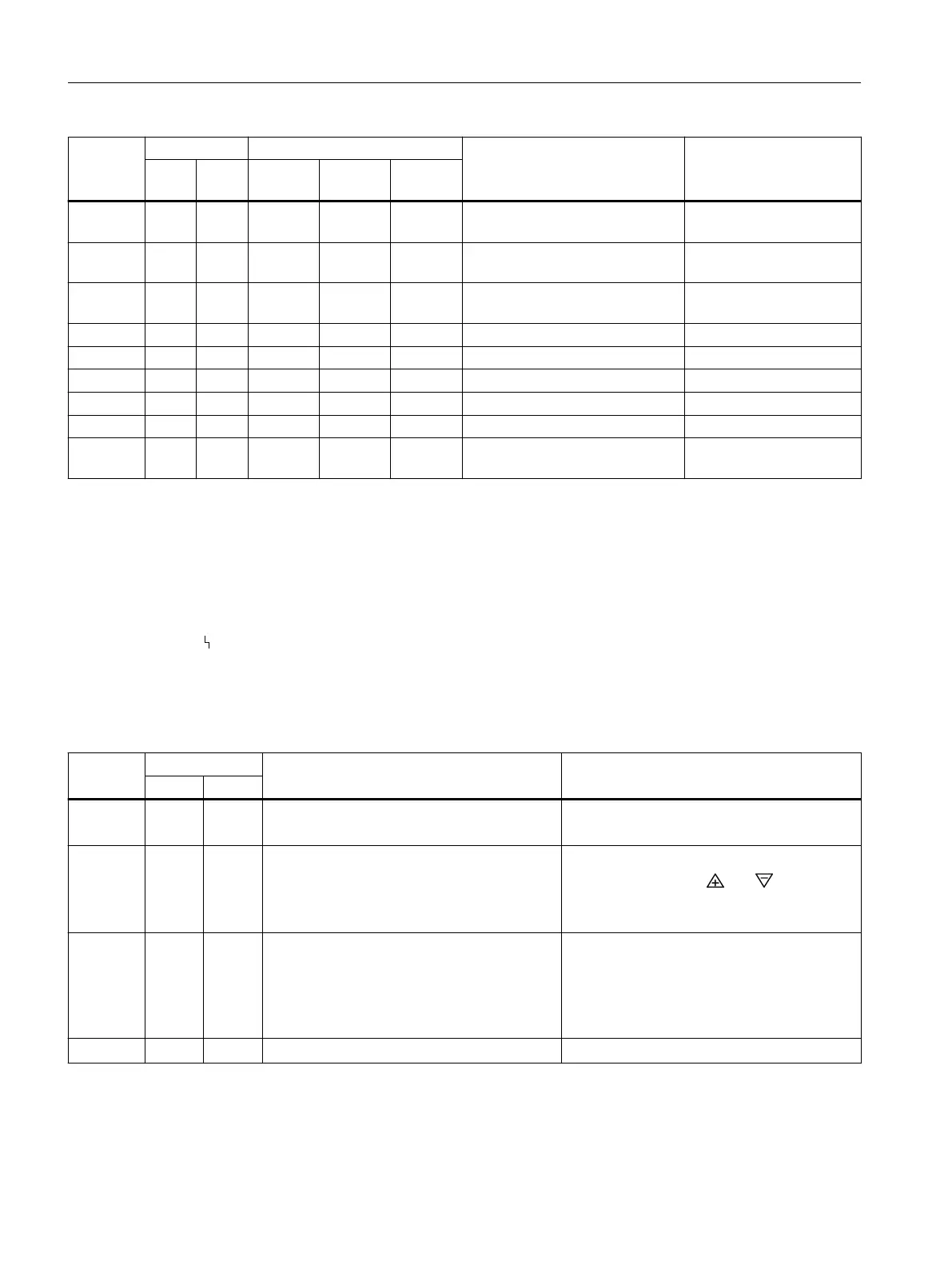

12.1.2 System messages before initialization

Remarks about the tables:

nn Stands for variable numeric values

Error symbol

/ (slash): the texts on the left and right of the slash flash alternately

Messages before initialization (first commissioning)

Message Line Meaning / cause Measure

Up Down

CPU

Start

X

X

Message after application of electrical auxili‐

ary power

● Maintenance

Pnnn.n X Potentiometer voltage of a non-initialized po‐

sitioner (P-manual mode) (actual position val‐

ue in % of the measuring range).

● Check whether the complete travel can be

covered using the and buttons and

that "P---" is never displayed.

● Execute the initialization process.

P--- X Measuring range was exceeded, the potenti‐

ometer is in the inactive zone, the transmis‐

sion ratio selector or the effective lever arm

are not adjusted as per the actuator travel.

● Switch the transmission ratio selector to

90°, especially in the case of part-turn

actuators.

● Adjust the effective lever length of linear

actuators as per the measuring range.

NOINI X Positioner is not initialized.

● Start initialization.

Diagnostics and troubleshooting

12.1 Output of system messages in the display

SIPART PS2 with PROFIBUS PA

250 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...