Note

Leakage

Besides continuous air consumption, a leakage can cause the positioner to try to compensate

the position deviation. This will result in premature wear in the entire control device.

● Check offline using the diagnostic parameter "11.LEAK" whether leakage is present.

● If there is leakage, check the pneumatic connections for leaks.

See also

Changing the operating mode (Page 101)

Diagnostic value '11.LEAK - Leakage test' (Page 261)

5.3.2 Pneumatic connection in non-flameproof enclosure

5.3.2.1 Structure of pneumatic connection

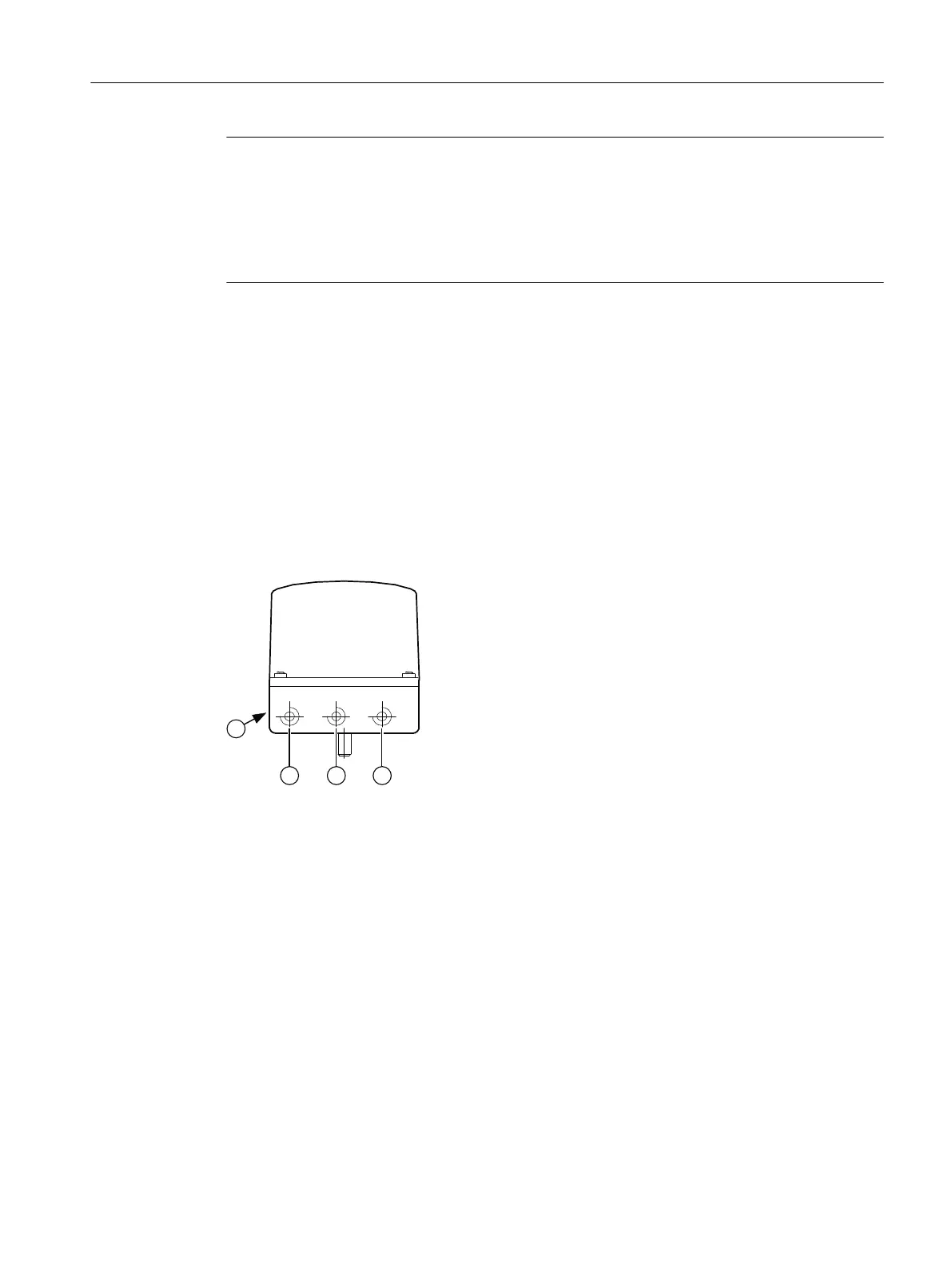

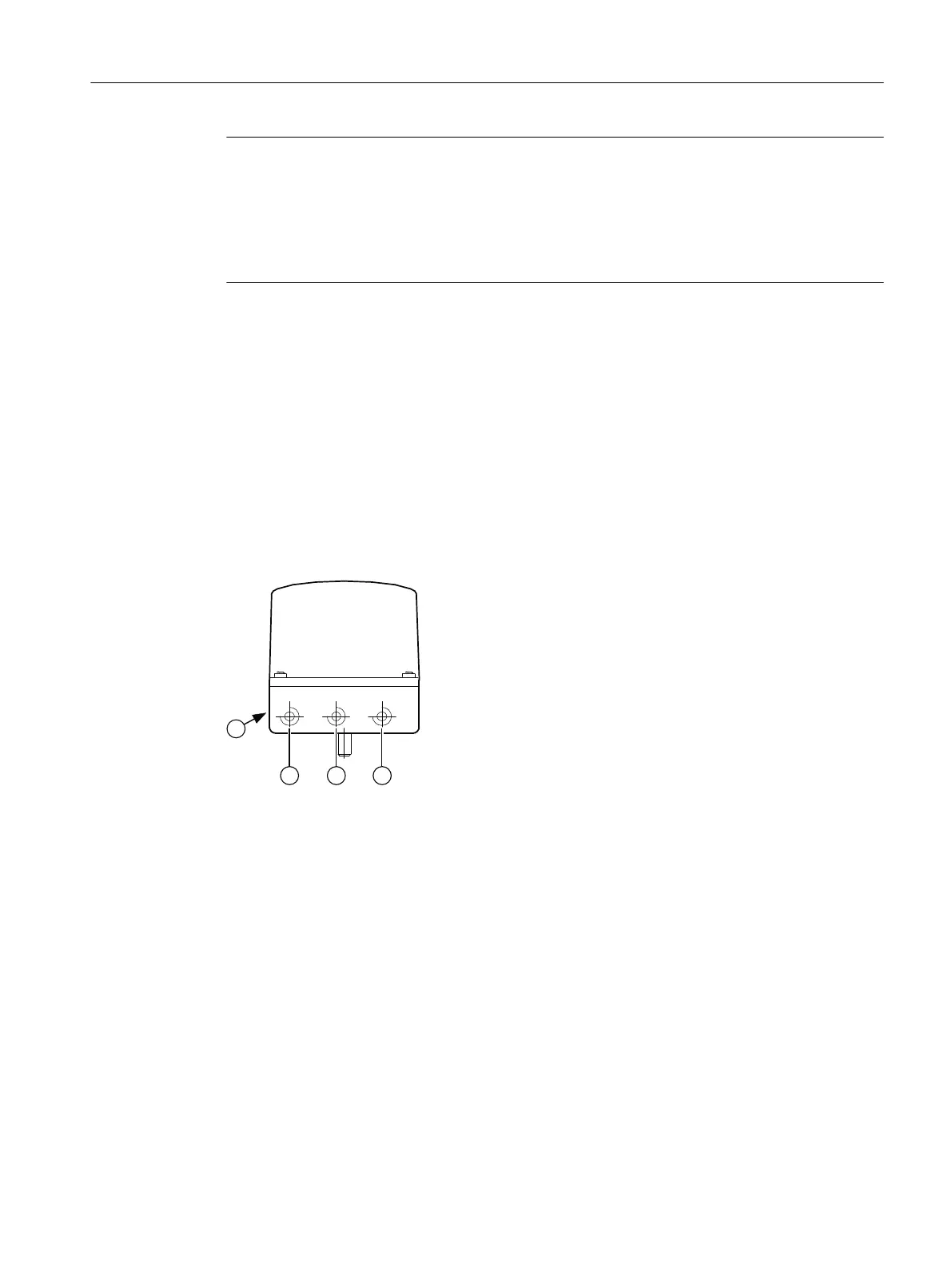

① Output: Actuating pressure Y2 *)

② Input: Supply air PZ

③ Output: Actuating pressure Y1

④ Exhaust air outlet with sound absorber, thread G¼

*) for double-acting actuators

Figure 5-11 Pneumatic connection, example

5.3.2.2 Integrated pneumatic connection

The following pneumatic connections are provided at the rear side of the basic device for the

integrated attachment for single-acting linear actuators:

● Actuating pressure Y1

● Exhaust air outlet

These connections are sealed with screws when the device is delivered.

Connect

5.3 Pneumatic connection

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 93

Loading...

Loading...