3.4.1 PROFIBUS system configuration

Overview

The positioner can be used in a number of system configurations.

Use with the SIMATIC PCS 7 Automation System is described below.

System communication

The Operator Station of the SIMATIC PCS 7 process control system allows easy and safe

control of the process by the operating personnel using OS Multi-Clients.

The Maintenance Station assists the maintenance engineer in guaranteeing high plant

availability, securing this long-term using optimization measures, and implementing the

maintenance measures using a minimum of personnel, materials, energy, costs etc.

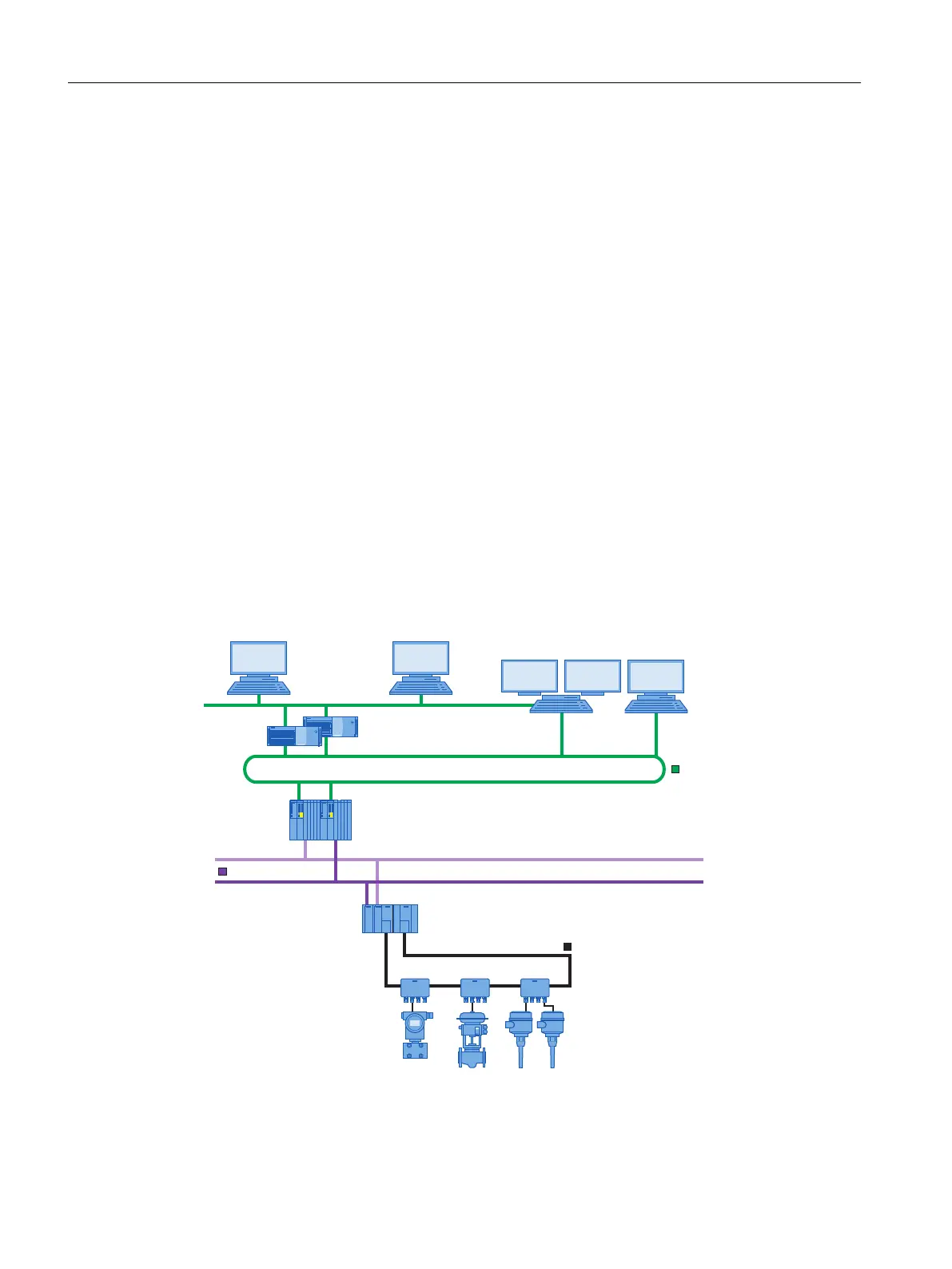

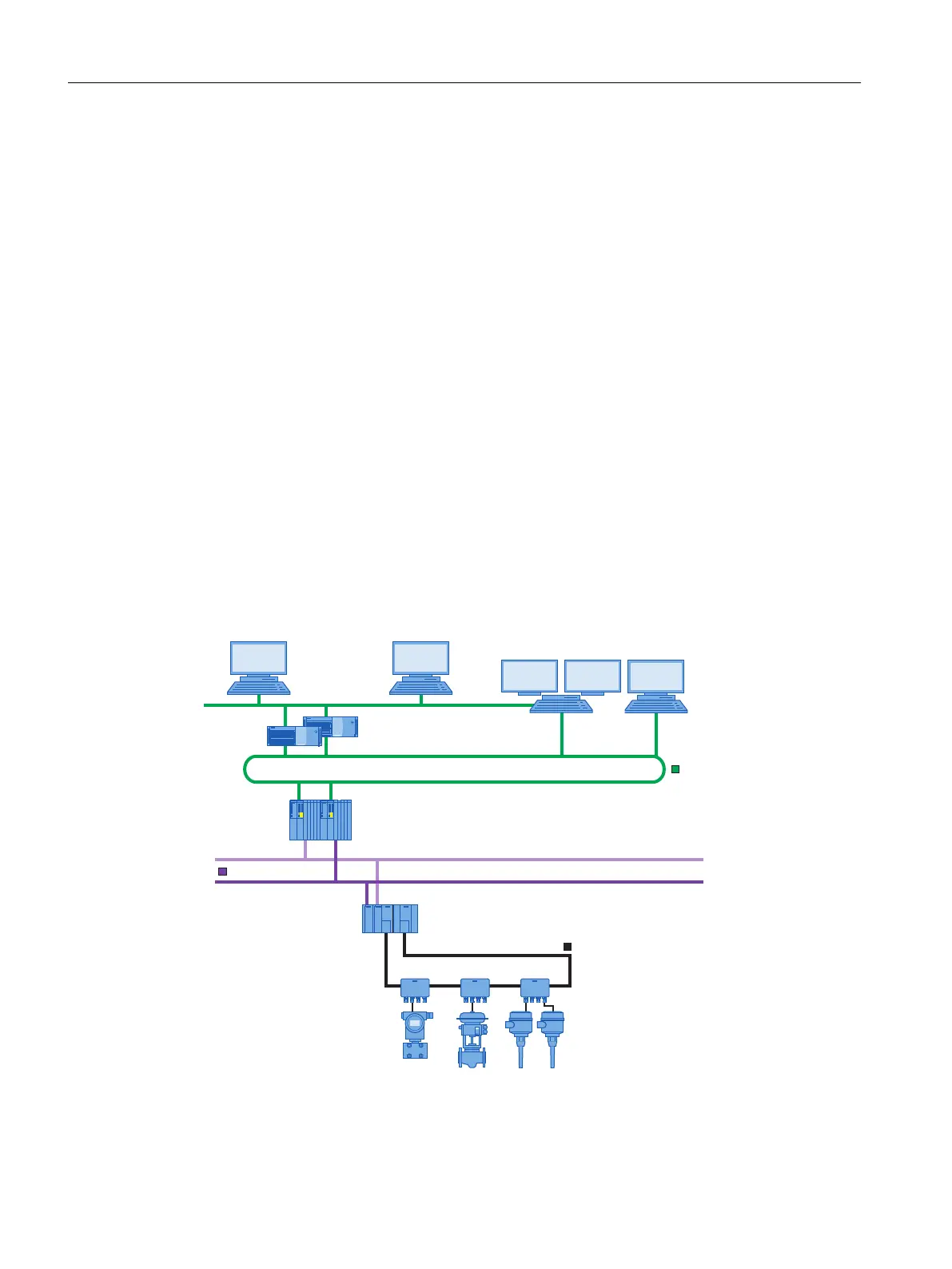

The field devices are integrated over PROFIBUS PA with:

● PA Link to the gateway between PROFIBUS PA and PROFIBUS DP

● Control system, e.g. SIMATIC PCS 7 Automation System, which communicates over

PROFIBUS

● Engineering Station, SIMATIC PDM (Process Device Manager) which communicates over

Industrial Ethernet

PROFIBUS PA

PROFIBUS DP

Industrial Ethernet

PA Link

SIMATIC PCS 7

automation system

Maintenance/

OS server

OS multi-clients

Engineering station

Operator station

SIMATIC PDM clients

Maintenance station

Figure 3-10 Typical system configuration

Description

3.4 Functional principle

SIPART PS2 with PROFIBUS PA

32 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...