The exhaust air outlet is corrosion-resistant for the blanketing of the pick-up room and the

spring chamber with dry instrument air.

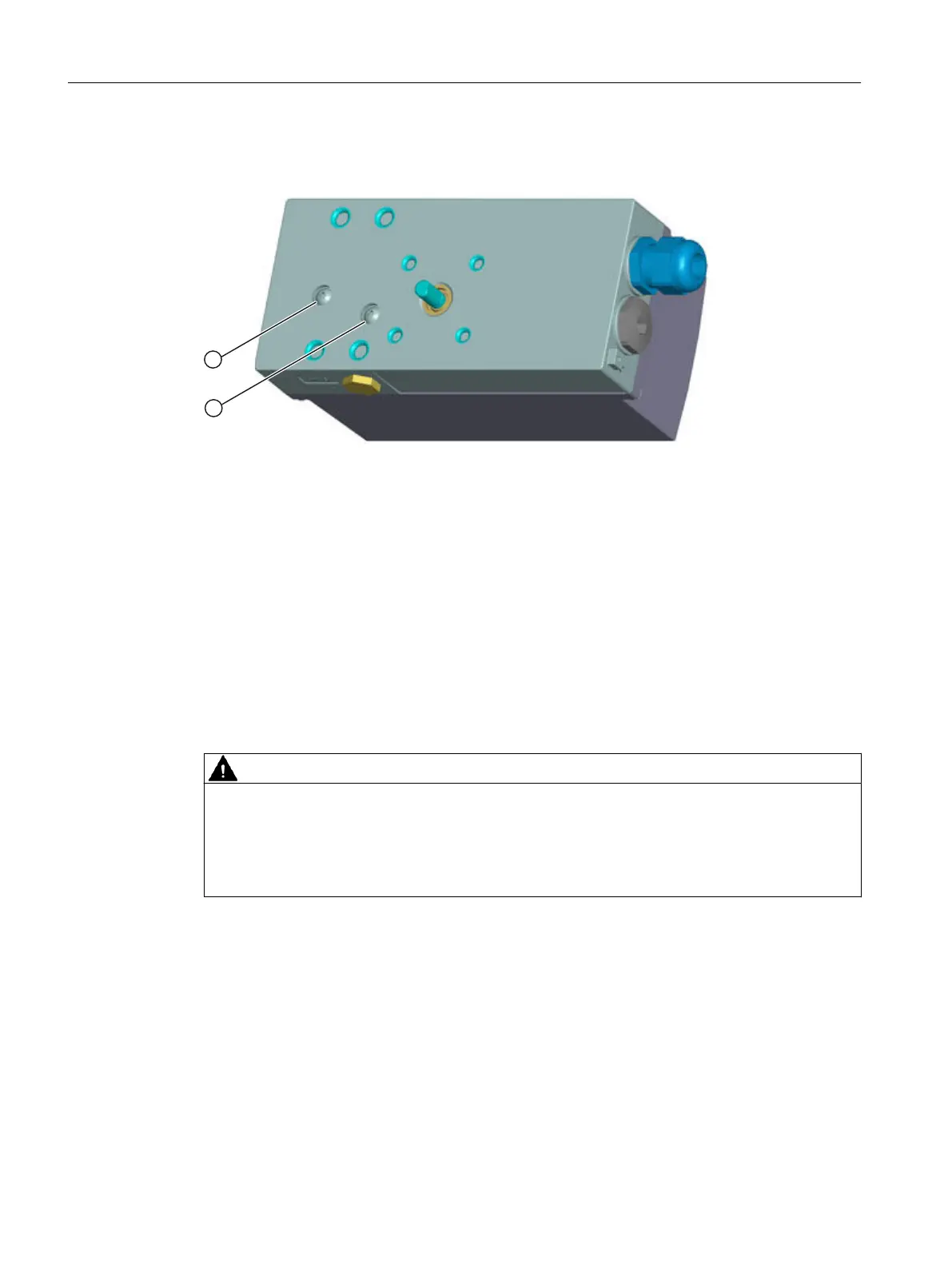

① Actuating pressure Y1

② Exhaust air outlet

Figure 5-12 Integrated pneumatic connection

5.3.3 Pneumatic connection in the flameproof enclosure

5.3.4 Reaction to failure of auxiliary powers

Overview

CAUTION

Before working on the control valve

Note that before working on the control valve, you must first move it to the safety position.

Make sure that the control valve has reached the safety position. If you only interrupt the

pneumatic auxiliary power supply to the positioner, the safety position may in some cases only

be attained after a certain delay period.

The difference between a failure of auxiliary pneumatic power and a failure of electrical auxiliary

power:

● Failure of electrical auxiliary power means:

– Failure of the bus voltage

– Failure or signal <4.5 V at input for the safety shutdown (terminals 82 and 82)

● Failure of auxiliary pneumatic power means the supply air PZ is interrupted.

Connect

5.3 Pneumatic connection

SIPART PS2 with PROFIBUS PA

94 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...