See also

Cleaning of the screens (Page 242)

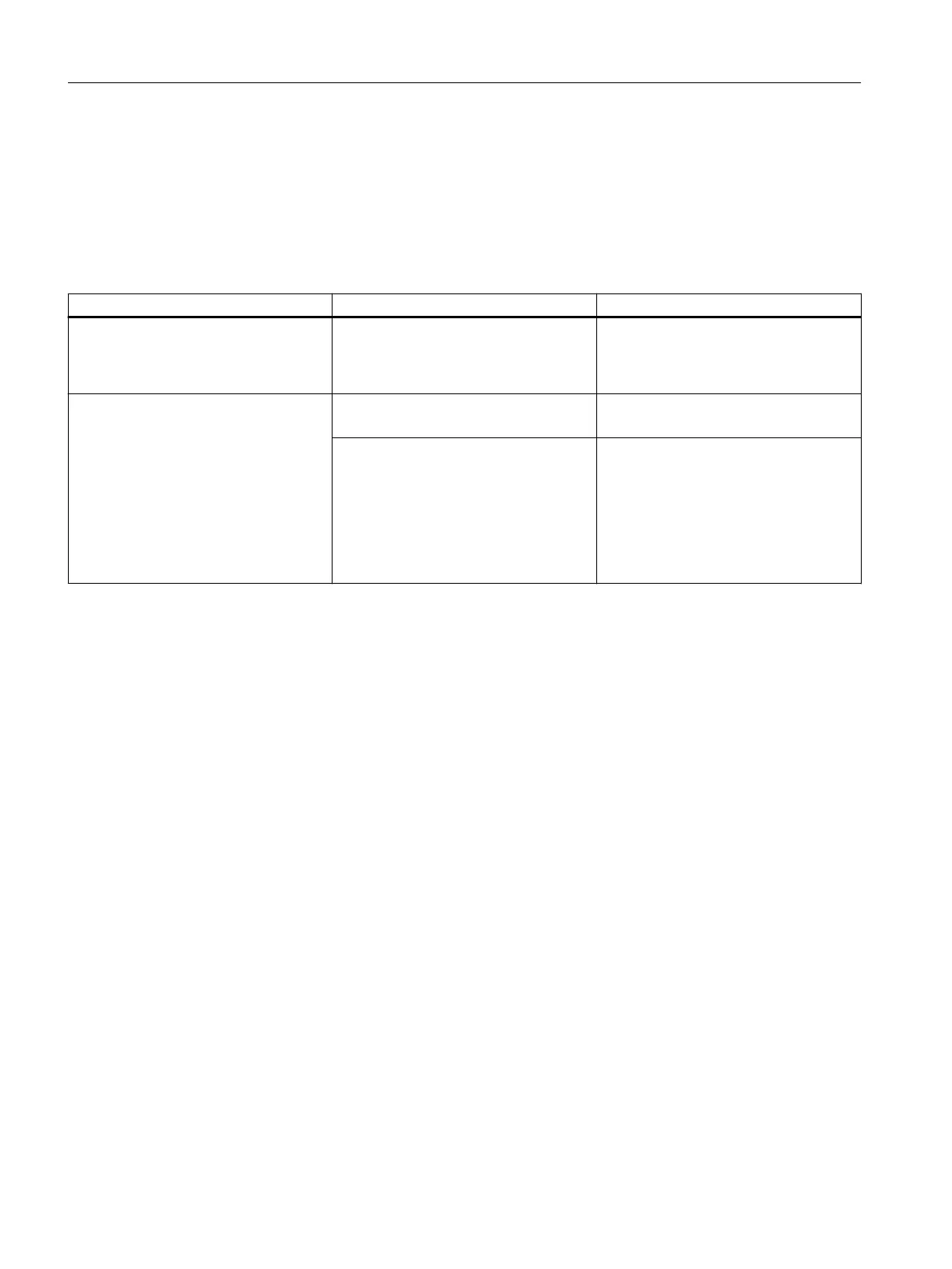

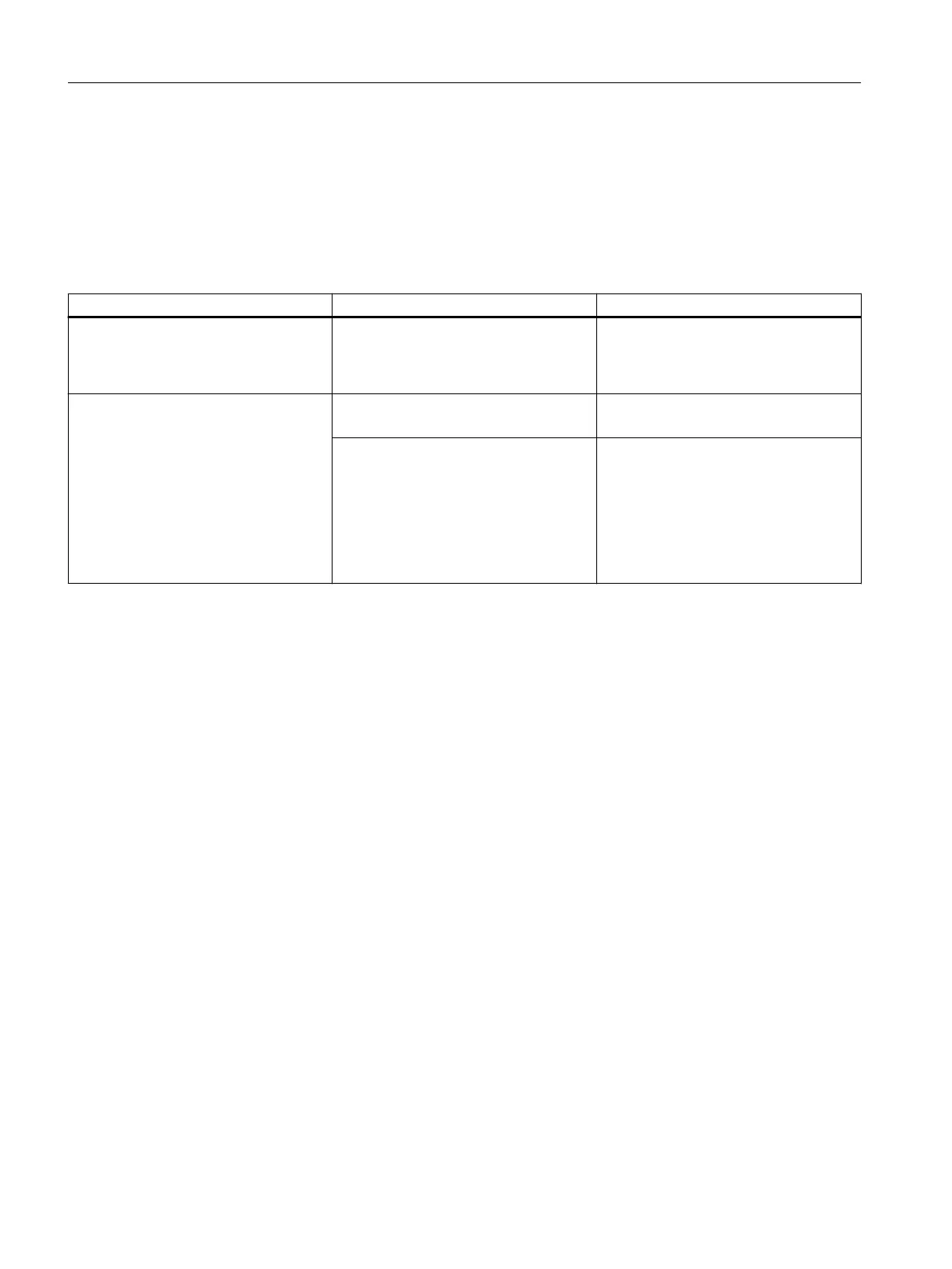

12.4.6 Remedial measures table 5

Fault profile (symptoms) Possible cause(s) Corrective measures

Zero point displaces sporadically (> 3%). Impact or shock loads result in acceler‐

ations so high that the friction clutch

moves, e.g. due to "vapor shocks" in va‐

por lines.

● Rectify the causes for shock loads.

● Re-initialize the position controller.

The device function has completely

failed: No representation on the display

either.

Electrical auxiliary power supply is not

adequate.

● Check the electrical auxiliary power

supply.

In case of very high continuous loads

due to vibrations (oscillations):

● Screws of the electrical connecting

terminals may be loosened.

● Electrical connecting terminals

and/or electronic components may

be knocked out.

● Tighten the screws firmly and secure

using sealing wax.

● Repair

● For prevention: Install the positioner

on the damping pads.

Fault table 5

See also

Repair/Upgrading (Page 244)

Diagnostics and troubleshooting

12.4 Fault correction

SIPART PS2 with PROFIBUS PA

280 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...