Alarm, error, and system messages

7.5 Wizard-based error messages

Operating with the Local User Interface

Operating Manual, 06/2017, A5E31930478-05

273

Wizard-based error messages

Overview

The following tables include descriptions of errors which may occur when executing wizard-

based processes. The wizard-based procedures especially include calibrations and AutoCal

procedures.

Note

Representation of wizard-based error messages in the logbook

Errors which prevent starting the wizard do not generate an entry in the logbook.

Errors which occur during execution of a wizard generate an entry in the logbook. However,

only the corresponding error nu

mber is entered in this case, not the message text.

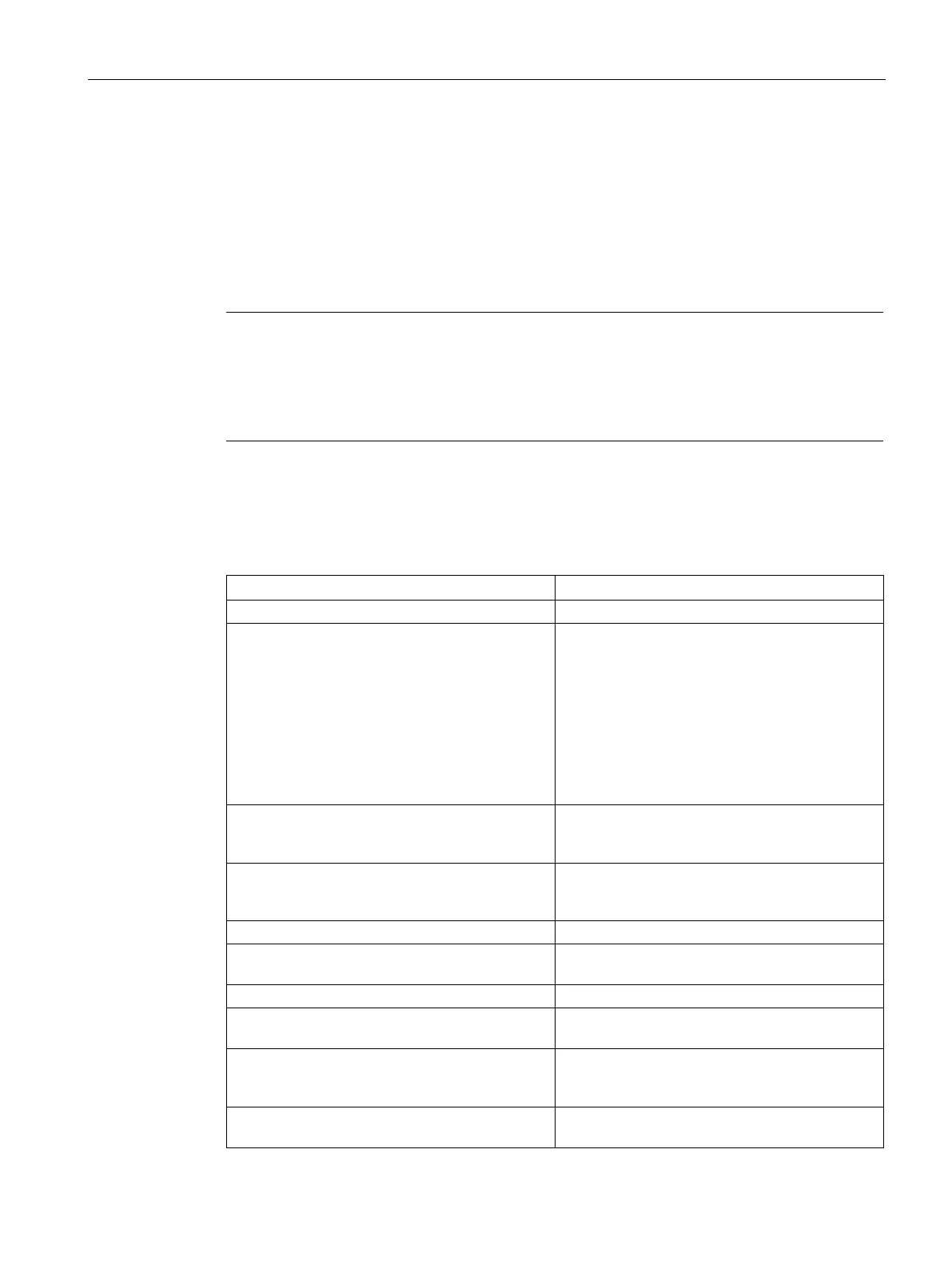

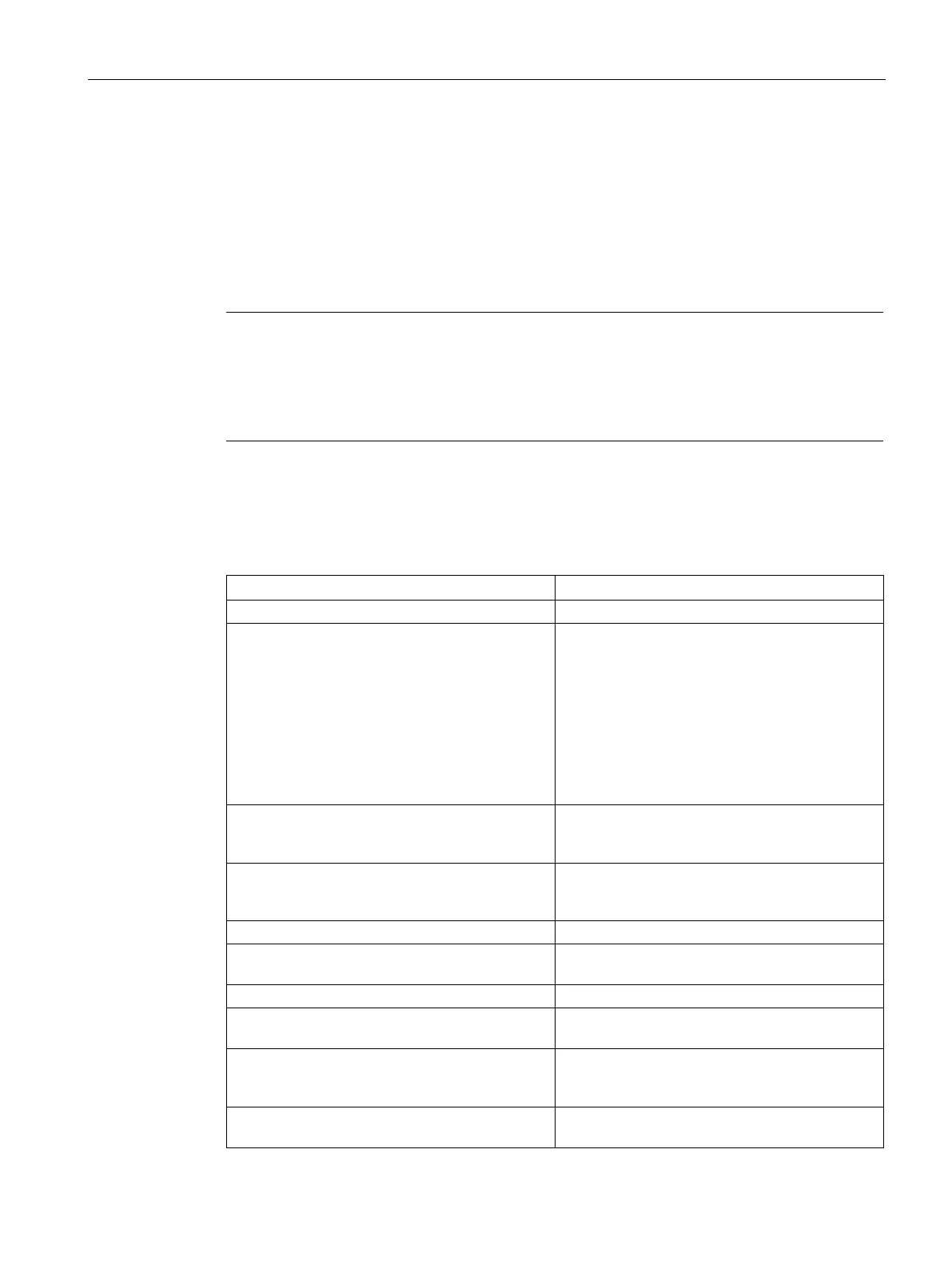

Table 7- 8 Wizard-based error messages (F1001, ... , F1031)

Message text (cause/remedy)

F1006 "F1006: The redetermined zero point and span

point deviate too much from the last zero point

and span point determined. The maximum per-

mitted deviation is set in the menu Calibration

tolerance. Possible causes:

1. An incorrect gas,

2. Faulty switching of the solenoid valves,

3. Different reference gas without new standardi-

zation or

4. A faulty analyzer module."

F1007

"F1007: The measured or calculated parameter is

outside of the permitted min/max limits. Check

your entries and setpoints."

F1008

"F1008: The gas flow is too low.

Check to see if the gas bottle is open or if the

correct valve is connected and turned on."

"F1009: Incorrect calibration gas detected."

F1010 "F1010: There are active errors. Correct the

pending errors and restart the wizard."

"F1012: Internal error occurred."

F1013 "F1013: A component could not be found. The

wizard cannot be started."

F1014 "F1014: The calibration type does not match the

selected components. Check the selection of

components or change the calibration type."

F1015, ... , F1017 "F101n: Internal error occurred. The wizard can-

Loading...

Loading...