Publication 1752-UM001A-EN-P - October 2006

84 Create Your Application Program

You can password-protect your application program to prevent

unauthorized editing, verification, or printing of programs. To create a

password, follow these steps.

1. On the Logic tab of the Controller Properties dialog, check the

Enable Password checkbox.

2. On the Change Password dialog, type in the password in the

New Password field.

Passwords may contain up to six characters.

3. Re-type the password in the Confirm Password field.

4. Click OK.

The password will be requested whenever the Edit button is clicked

to open the Logic Editor. You can upload or download the program

without the password, but program edit, verification, print and report

functions are not available.

Programming Basics

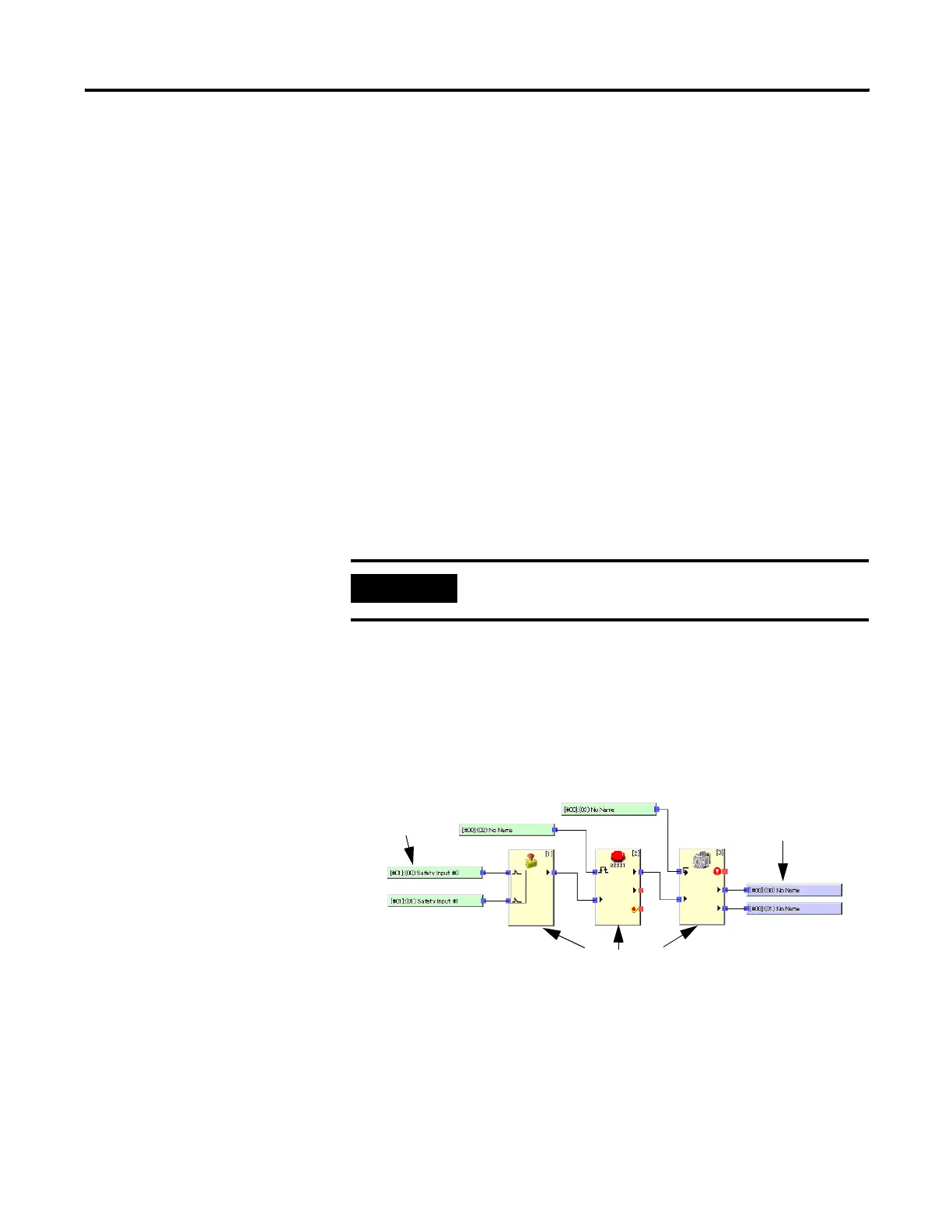

Programs are created from logic functions and function blocks that

indicate commands, from input tags that indicate data input sources,

and from output tags that indicate data output destinations. The I/O

are connected with connection lines.

I/O Connections

IMPORTANT

If you forget the password, it cannot be recovered.

Input Tags

Output Tags

Function Blocks

Loading...

Loading...