ATTENTION

This test requires a minimum of one NIM and one server (other UCN nodes). With only two

nodes, the NIM talks point-to-point. Three nodes are required for true triangulation.

Introduction

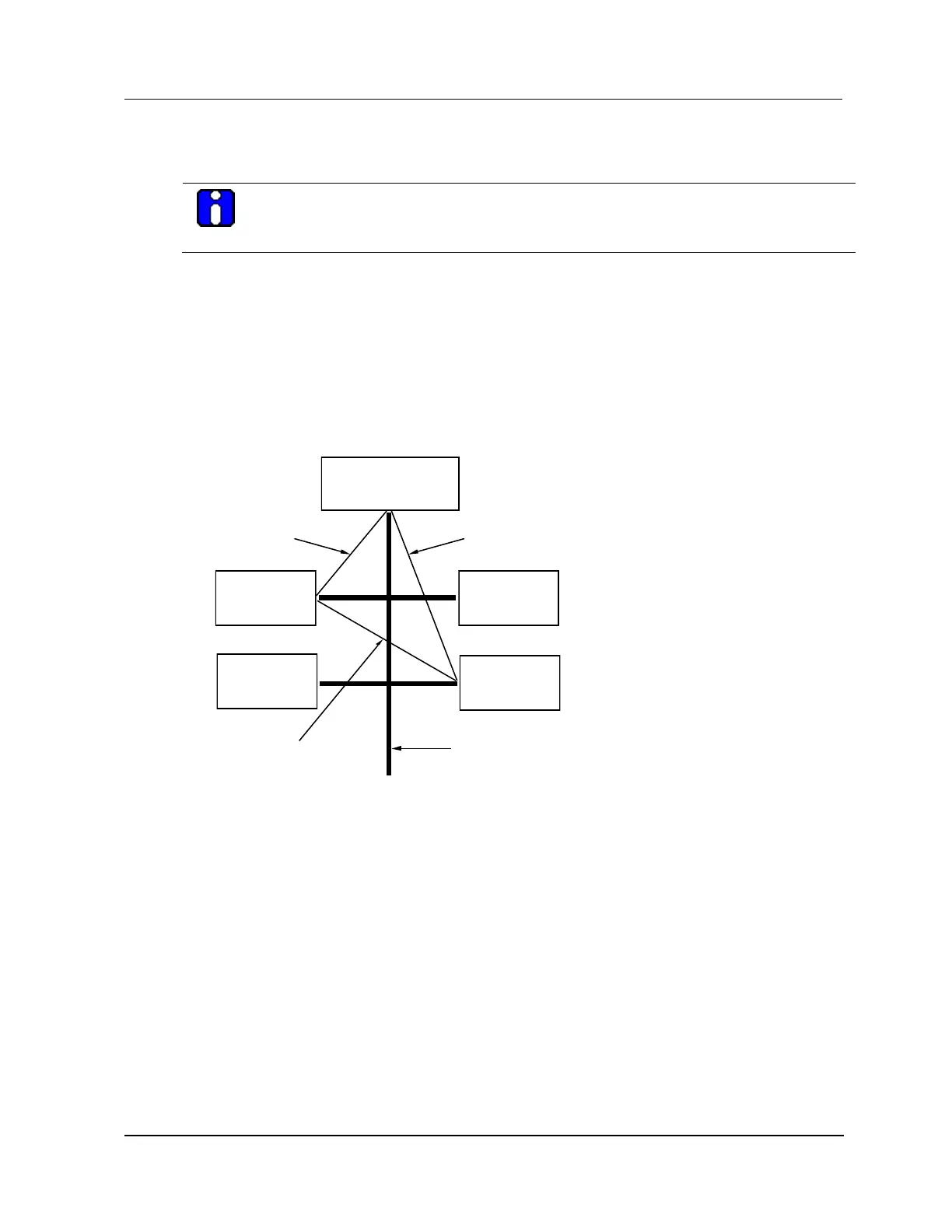

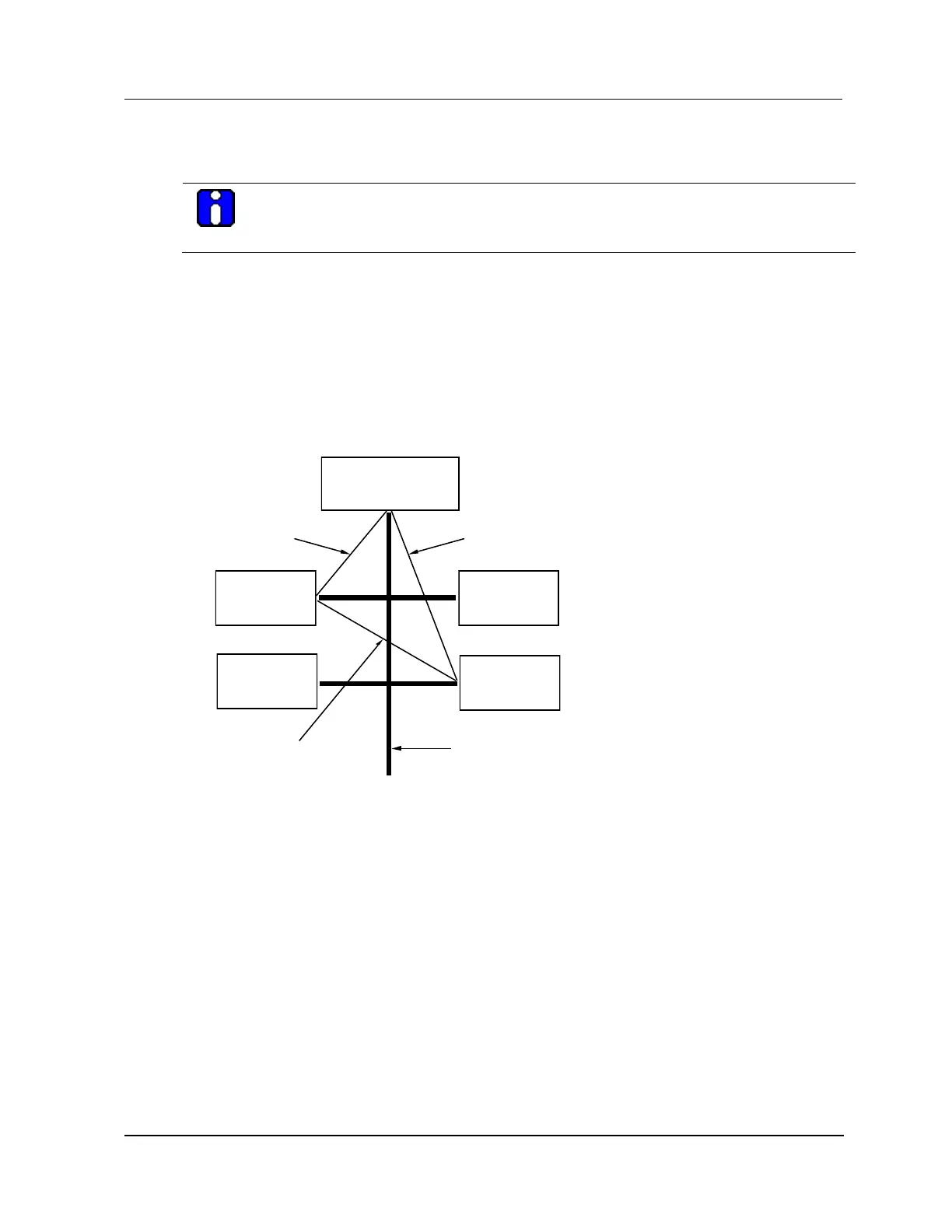

In the triangulation test, as illustrated in the following figure, only nodes that are configured in the test

are capable of token passing participate. For example, HPMs that have not been loaded, cannot pass

tokens and therefore do not participate. For those nodes that do participate, the test Master issues a

message to another node in the test and requests the message to be forwarded to a third node. The third

node in the test then sends a message back to the test Master, which verifies that the path has

successfully completed. While passing the message, the following communication paths are checked:

Master (NIM) to Slave 1, Slave 1 to Slave 2, and Slave 2 to back to the Master.

Figure 192 Triangulation Test

Timeout policy

Because a message may be lost or an error may occur, the Master has a reasonable timeout policy for

receiving the response back from Slave 2. The timeout policy assumes that each Slave in the test is

serving only one Master. This means that responses arriving late are considered errors. By examining

several paths together, it is usually possible to determine which nodes are experiencing communication

problems.

Loading...

Loading...