7 IOP Calibration Procedures

7.4 LLAI IOP Calibration Procedure

442 HPM High-Performance Process Manager Service R688

Honeywell December 2020

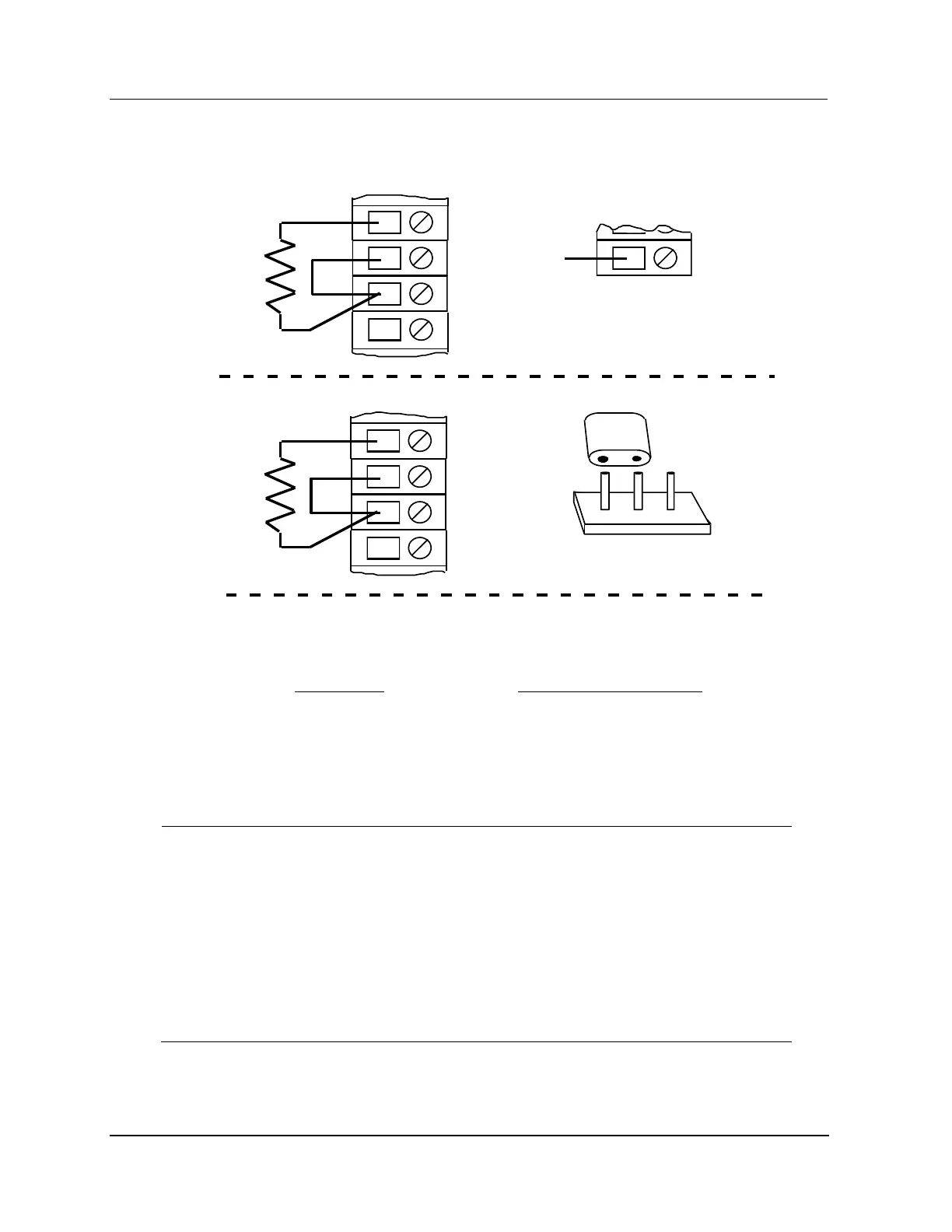

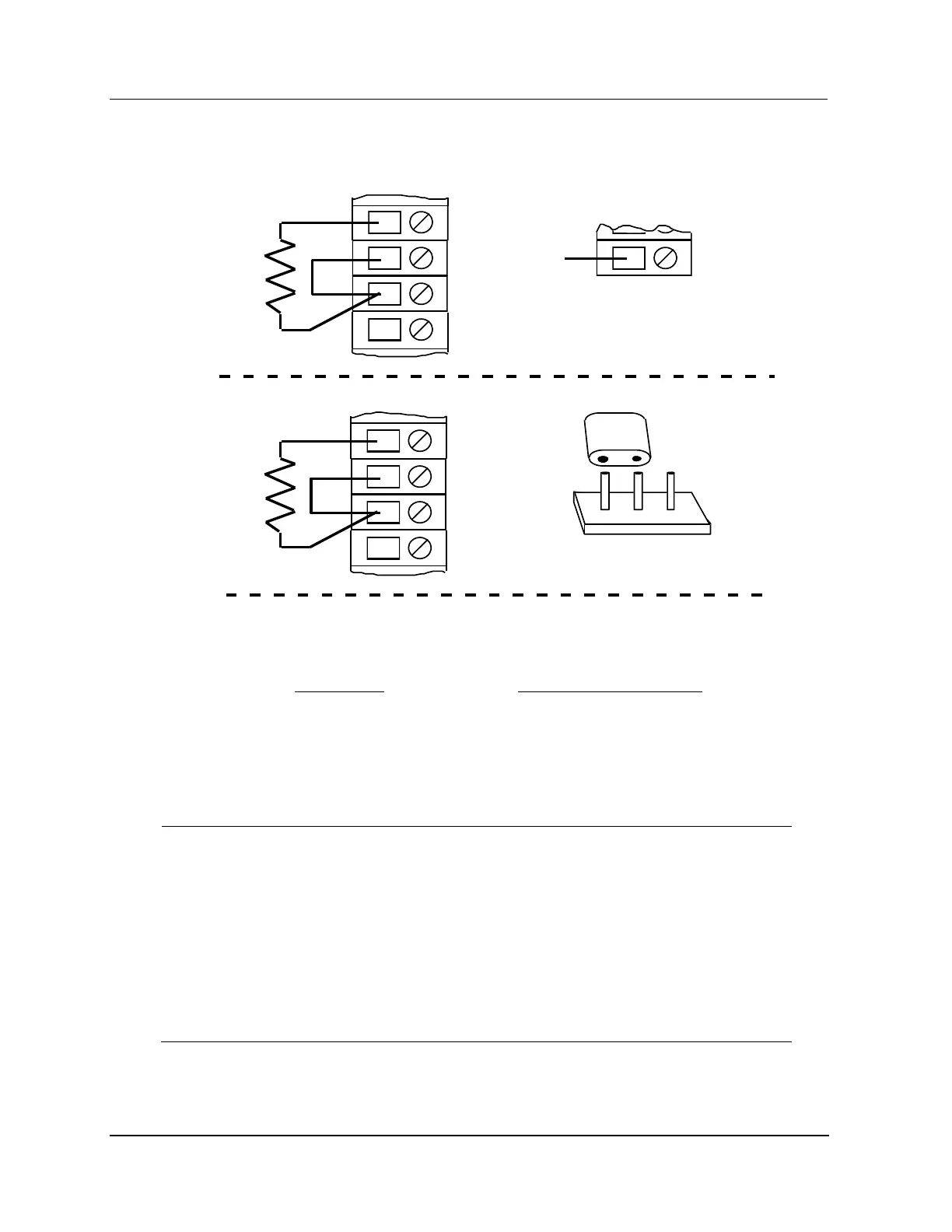

Figure 212 RTD Full Scale Calibration Circuit Cu: 10 Ohm, Pt: 100 Ohm, Ni: 120 Ohm

Be sure there is one wire connected to the "A" terminal and one wire connected to the "B"

terminal. There should be two wires connected to the "C" terminal.

RTD Input Type

Cu: 10 Ohm

Pt: 100 Ohm

Ni: 120 Ohm

100 Ohm

500 Ohm

500 Ohm

Precision Resistor (R cal) Value

Note:

A

B

C

Shield

Model MU/MC-TAIL01 and MU/MC-TAIL02 FTAs

Model MU/MC-TAIL03 FTA

A

B

C

Shield

1 3

Install the jumper between pins 1 and 2.

2

P1

NC

17

TB2

Remove the wire between

TB-1 and TB2-17.

R cal

R cal

Reference

2485

Again, momentarily short the calibration pads at the upper-left corner of the FTA under

test, then check the STATUS indicator (DS1) on the LLAI. The STATUS indicator

remains extinguished for approximately 30 seconds while the IOP card performs its

"full-scale" calibration.

If a thermocouple input is connected to the LLAI subsystem, it is recommended that

you recalibrate the Reference Junction (RJ) input each time the thermocouple is

recalibrated. Only channel 1 requires a zero ohm jumper connected to it.

Connect a zero-ohm jumper to channel 1 as illustrated in Figure 213. Repeat steps 3

and 4.

Connect a 2 kohm resistor jumper to channel 1 as illustrated in Figure 214. Repeat step

6.

Loading...

Loading...