CHAPTER 3B ENGINE 50cc/80cc ATV SERVICE MANUAL09.0

CHAPTER 3B ENGINE PAGE 3B - 13 -

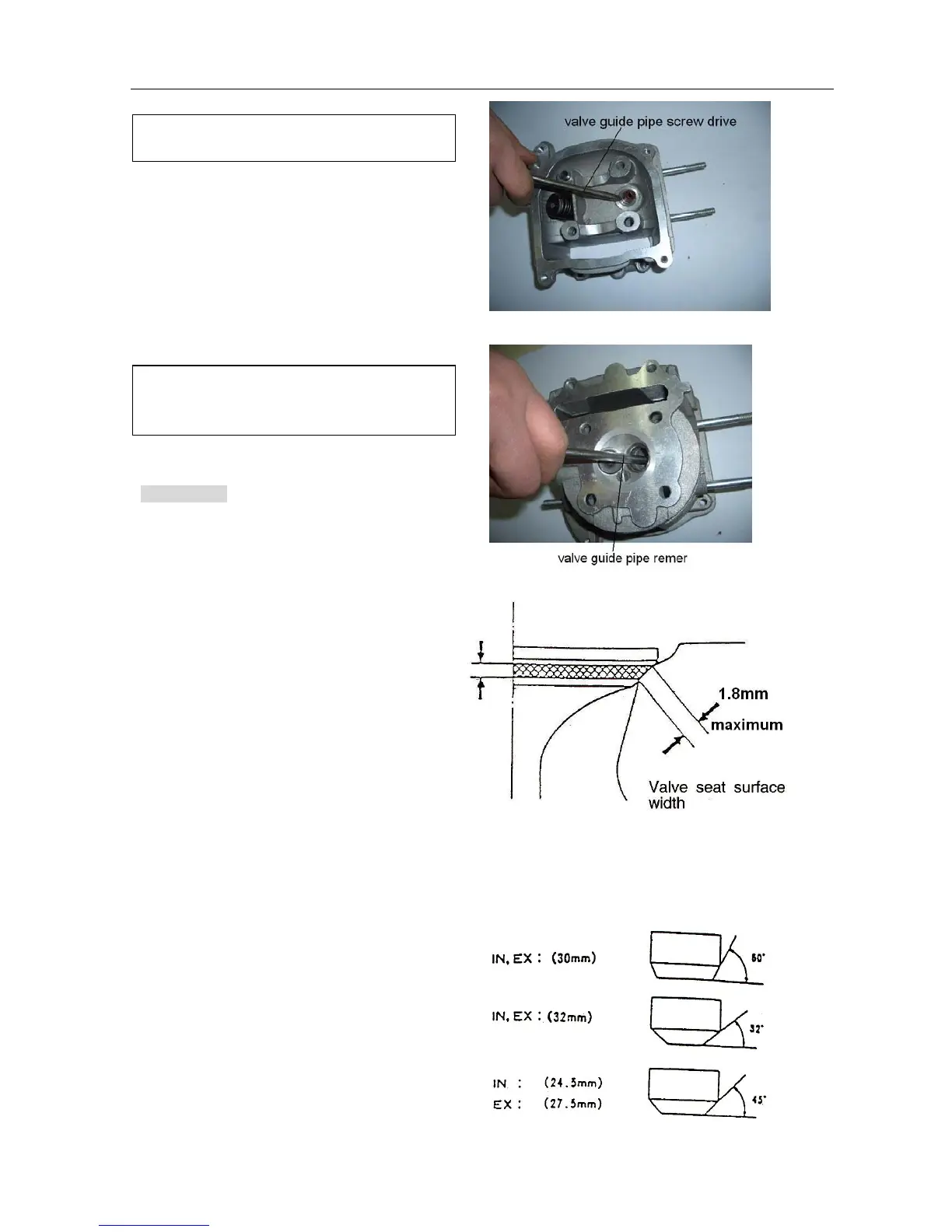

pry out valve guide pipe

Be careful to not damage cylinder head

Surface.

Press in the new valve guide pipe.

Spread engine oil on new O-ring and build up

new valve guide pipe.

Make sure cylinder head is still warm when

pressing in new guides.

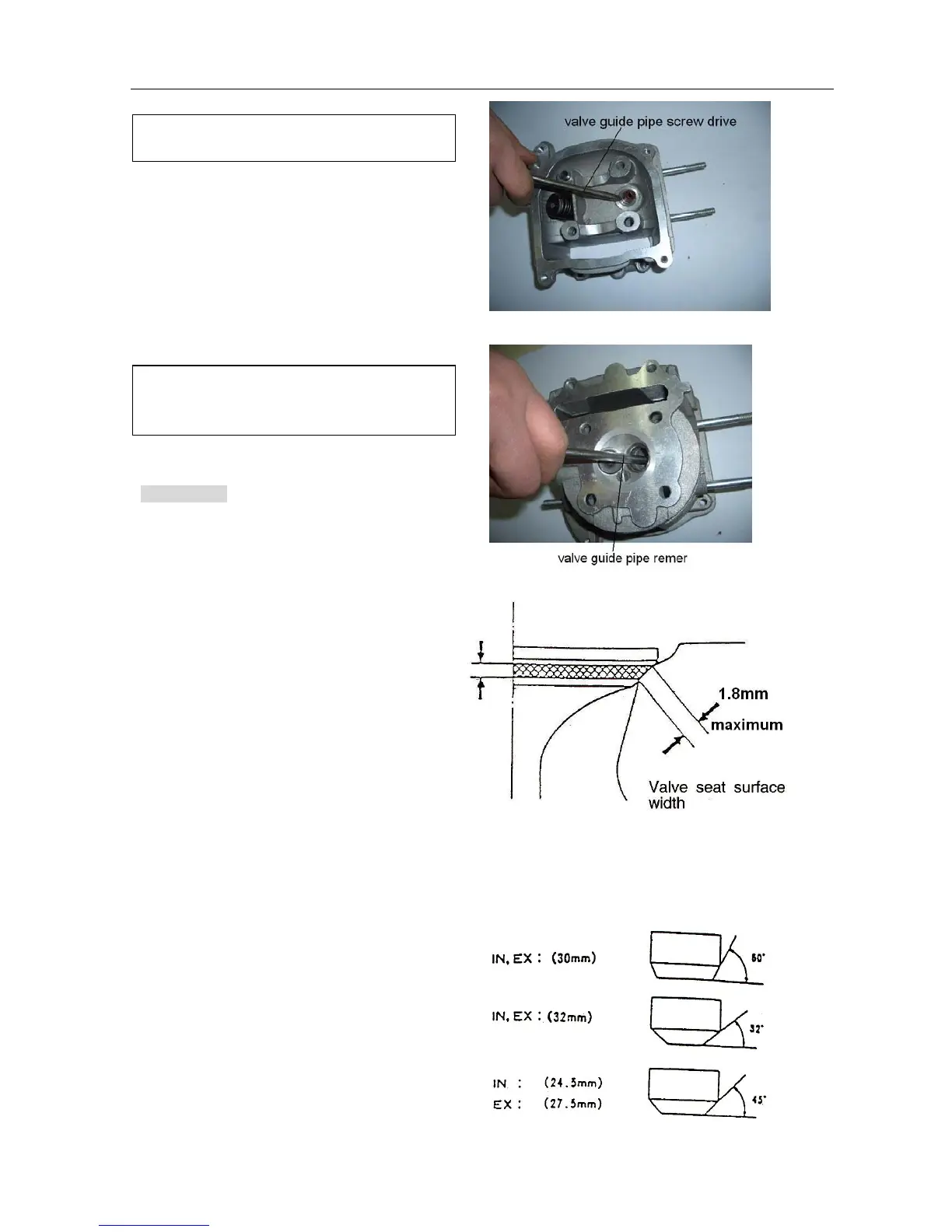

Size valve guide with reamer after installing.

·Use cutting oil on reamer.

·Rotate reamer in proper direction and do not

stop rotation to push in or pull out.

Clean cylinder head and get rid of cut bits of

metal and dust.

Special tools

Valve guide pipe reamer

Valve seat checking and correcting

Valve seat checking

Get rid of carbon deposit from combustion

chamber and valves.

Spread emery on seat surface between valve

and valve seat.

Use polishing bar to wear-in valve.

Take out valve and check valve seat surface.

Change if valve surface is coarse or facial

polished.

Valve seat surface width checking.

Used limit: above 1.8mm correct.

Correct valve seat by chamfered tool if

surface width is not even or too wide and too

narrow.

Valve seat chamfer cutting tools

Refer to valve chamfered tool handbook for

detailed.

Press and rotate with 4-5 kg (10-12lb) force

to polish and cut when correcting.

Use chamfered tool after spreading engine

oil on it.

Loading...

Loading...