CHAPTER 3B ENGINE 50cc/80cc ATV SERVICE MANUAL09.0

CHAPTER 3B ENGINE PAGE 3B - 54 -

3.8.1General Information:

WARNING! Work on the fuel system in a well-ventilated area free form sparks or open

flames. Do not breath the vapors from the gasoline. Wear protective gloves to prevent skin

irritation.

·Open the bowl drain and allow all gasoline in the carburetor to drain into an appropriate container

prior to removing or servicing it.

·Remove control cables and wires carefully to prevent damage.

·Check all ‘O’ rings for damage. Replace as necessary.

·Remove carburetor from the scooter before attempting to service the fuel bowl or vacuum

diaphragm.

·When cleaning the carburetor, remove the vacuum diaphragm before using air or solvents for

cleaning. This will prevent damage to the diaphragm.

·When storing the scooter for any period of time exceeding one month, use a quality fuel stabilizer to

prevent deterioration of the fuel and damage to the carburetor.

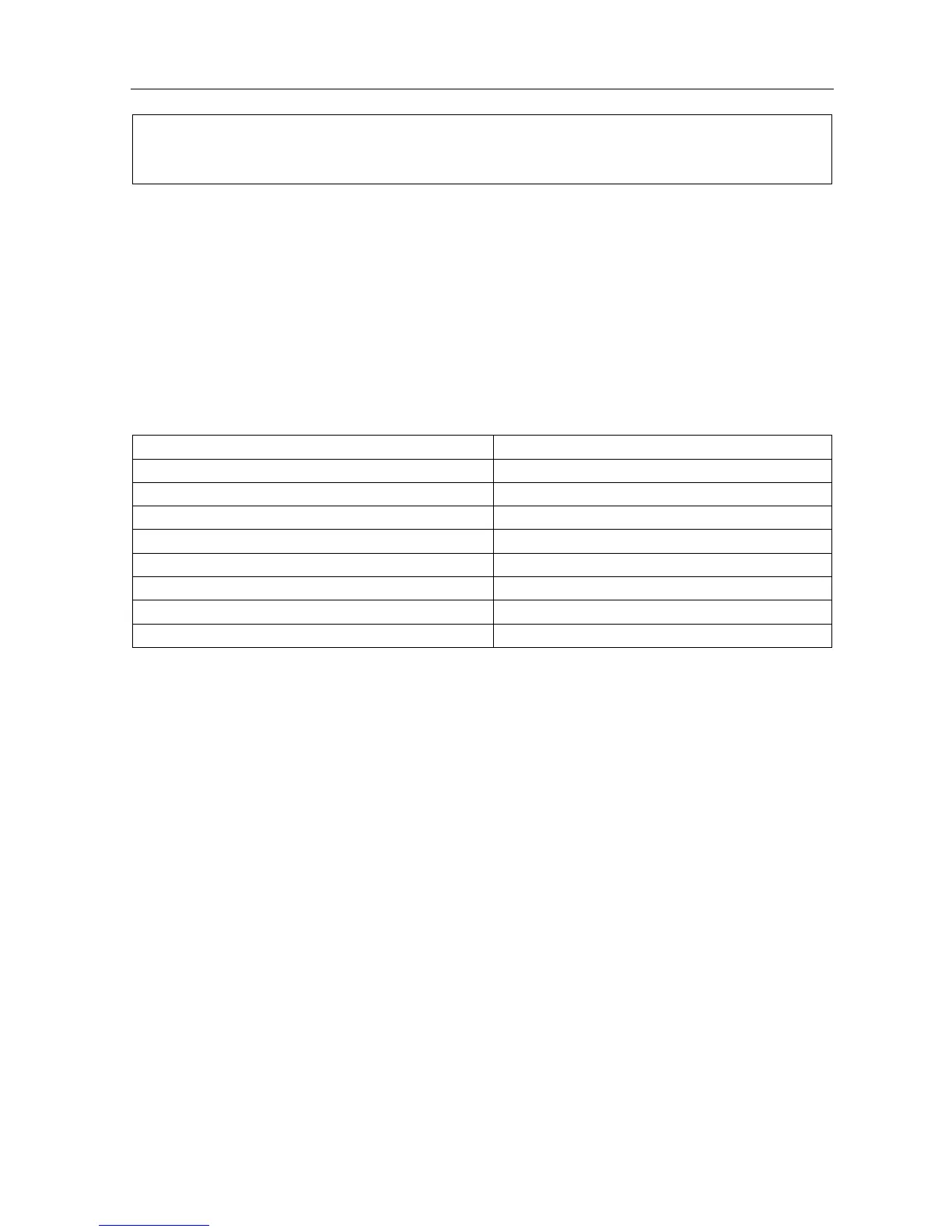

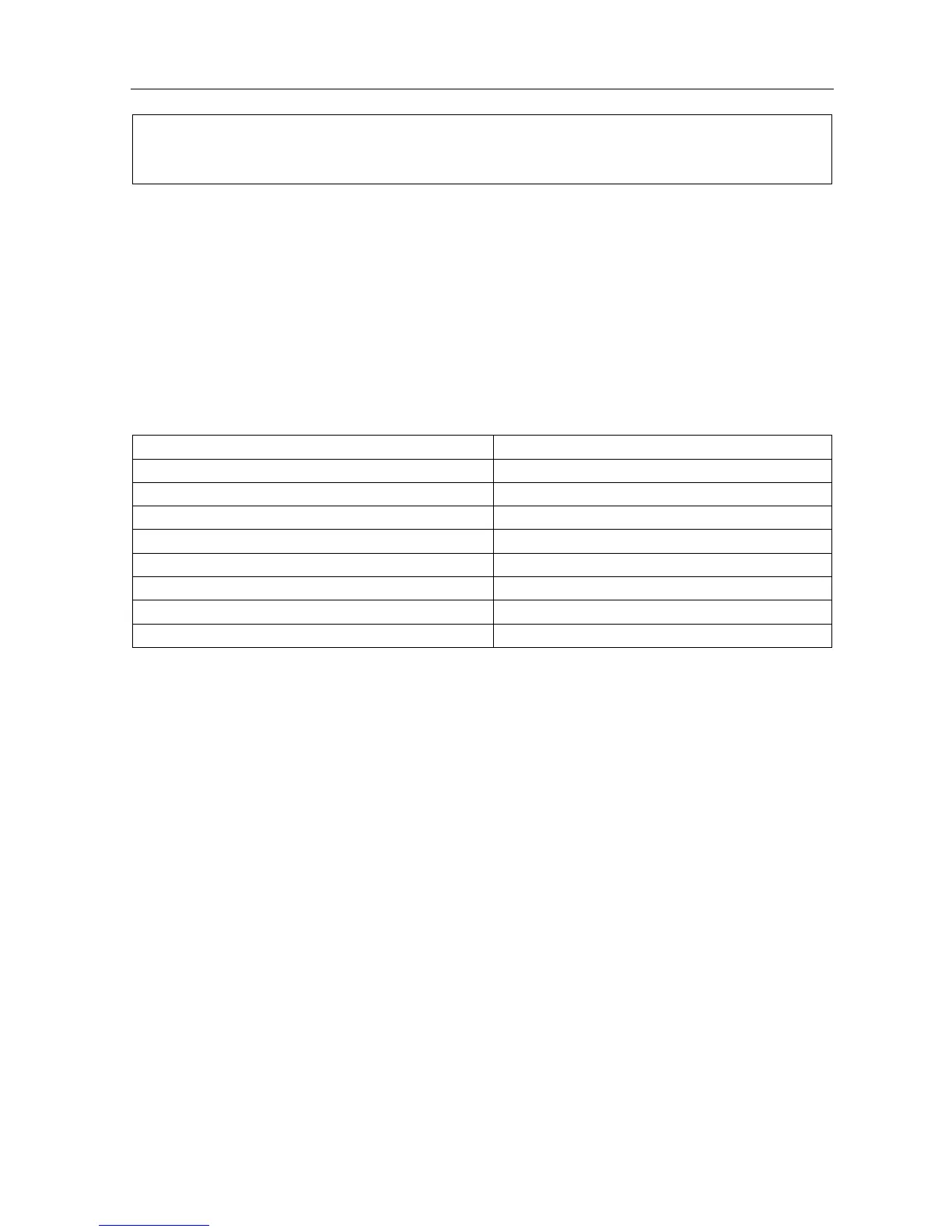

Repairing material

Specification standard valve

Carburetor Constant velocity-CVK

Venturi Bore 18mm

Fuel level 20.5 mm

Main Jet #82

Idle Jet #35

Idle Speed

1900±190 RPM

Throttle Free Play 2-6mm

Mixture screw setting

2 turns±1/4 turn

Special tools required- Float Gage

Troubleshooting

Hard Starting Engine Poor Drivability

·No Spark ·Weak spark/Bad Ignition System

·Low Compression ·Blocked fuel line

·No fuel in carburetor ·Blocked fuel filter

-Blocked fuel line

·Bad fuel

-Blocked fuel filter

·Water in fuel

-Blocked vacuum line

·Air leak at carburetor or manifold

-Leaky vacuum line

·Improper float level

-Dirty float needle

·Bad auto chock

-Float set too high

·Obstructed jet in carburetor

Too much fuel to engine

·Vacuum slide stuck

-Blocked air filter

·Damaged vacuum diaphragm

-Manifold air leak

·Dirt in carburetor

-Bad auto choke

-Blocked air passage in carburetor

Air/Fuel mixture too rich or too lean

·Bad auto choke

·Plugged idle jet

·Float needle stuck or dirty

Loading...

Loading...