Technical Information

70

DGC 6xxx

Here the air is passed between two metal plates. The top metal plate is

cooled via the ambient temperature. The bottom metal plate is cooled by the

air from the cooling fan. Water from the steam condenses out on these two

metal plates.

Condensate flows down the plates and collects on a ledge in the bottom of

the condenser. The condenser is mounted at an angle and the condensate

flows towards an opening. From here water flows directly to the sump of the

residual water pump. The hot air then passes through the large opening in

the bottom part of the condenser where it is mixed with the cool air from the

cooling fan and expelled from the appliance. In this way the air passing out

under the fascia is cooled.

2.4 Fan Run-On

After cooking, to ensure that remaining vapors in the cavity are removed in a

controlled manner, the fan continues to operate for a certain period after the

appliance has been switched off.

The fan run-on prevents condensate deposits from collecting on the fascia

panel and furniture front panels when the door is opened.

Any hot food left in the oven will delay cooling and lead to a longer fan run-on

time. The fan run-on duration cannot be modified!

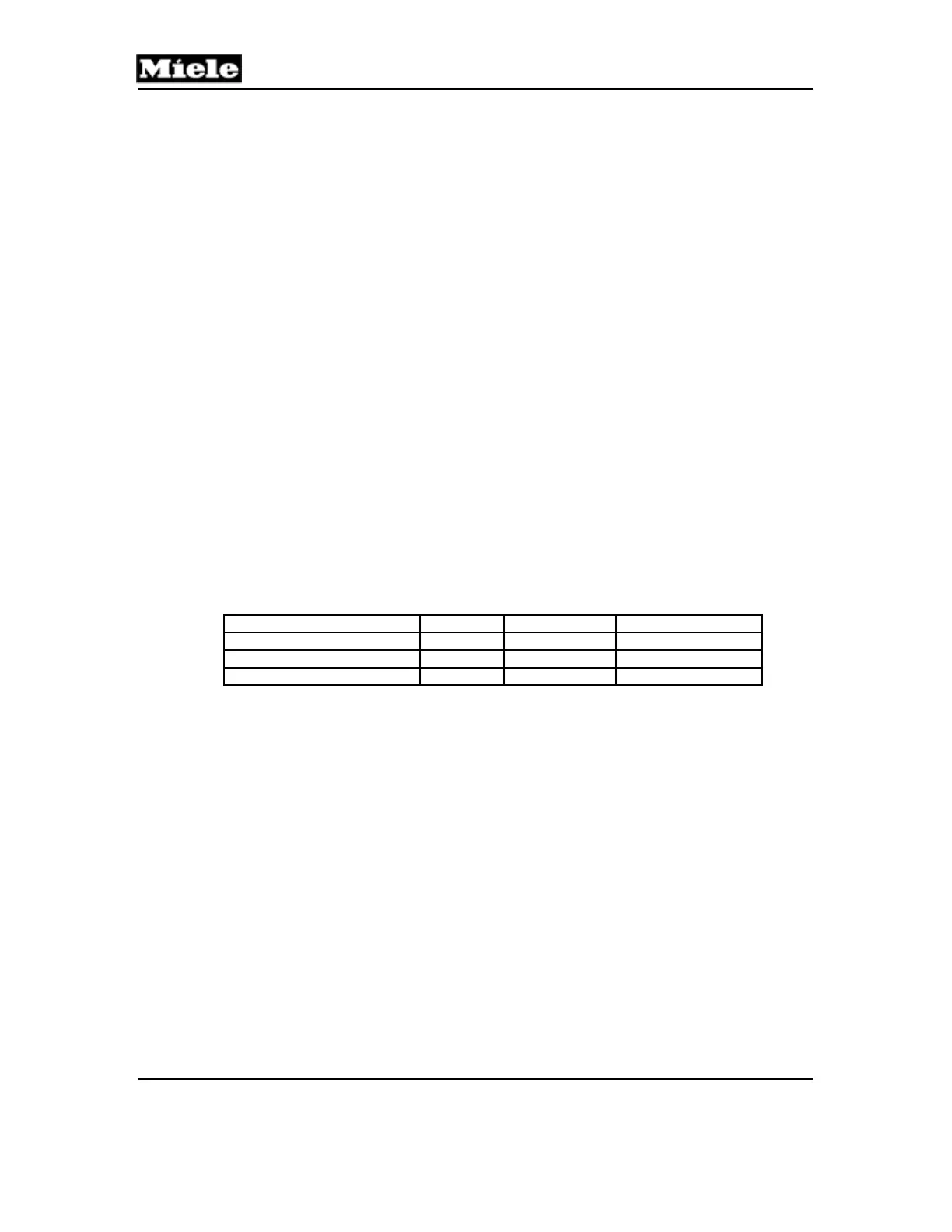

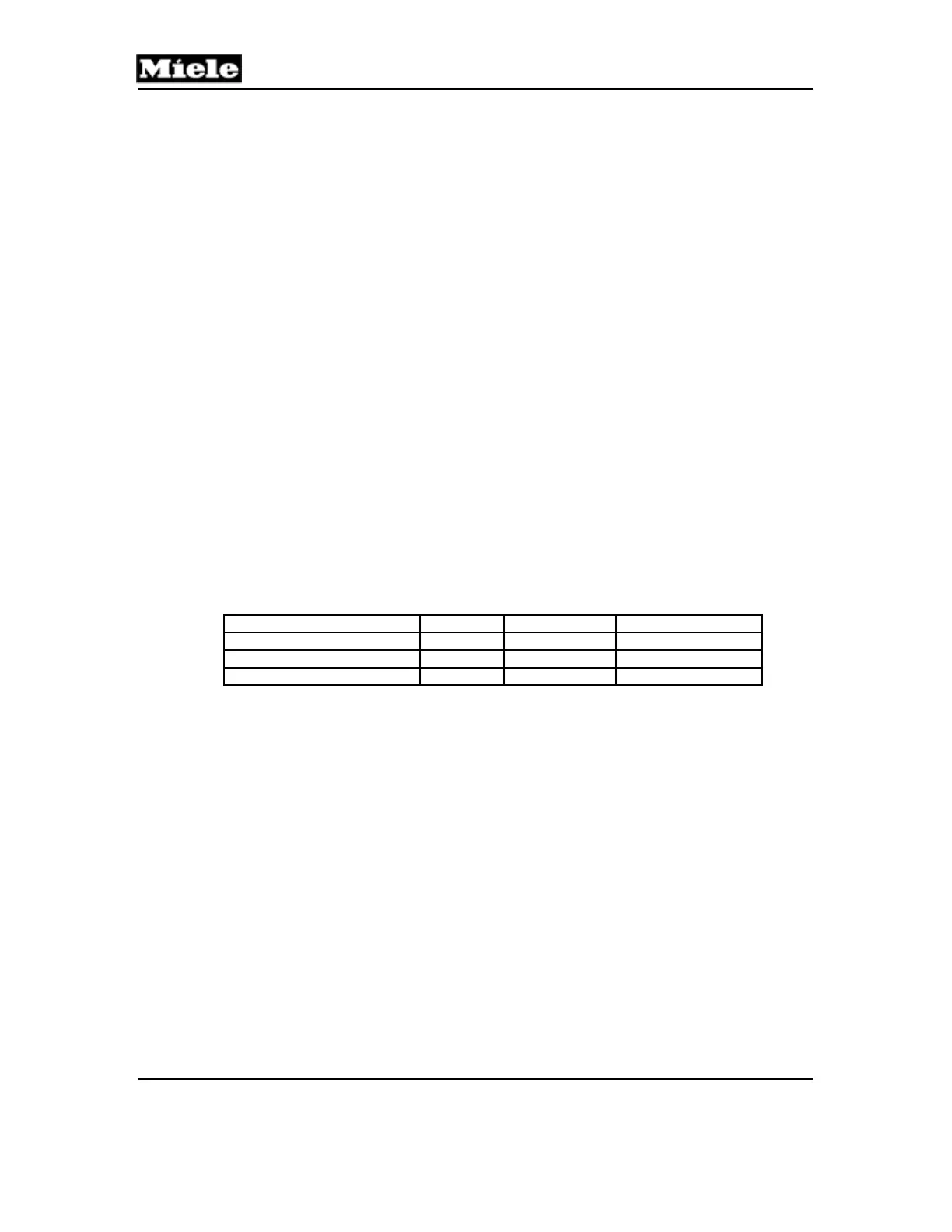

The fan run-on is temperature-dependent and has 2 power levels:

Temperature Of

On (low level) On (normal level)

Below 113°F X

117°F - 244°F X

Above 248°F X

Table 045-5: Fan Run-On Data

2.5 Steam Cooling/Combi Cooking

2.5.1 Steam Cooking 212°F

Convection fan run at half speed.

Heat-up phase.

1. Filling of steam generator for max. 60 seconds. Top/bottom heater

elements activated, 1800W. Use of part of water intake cycle. Cavity

is preheated.

2. Steam only, 3300W, until temperature of 176°F is reached in oven.

Temperature band crossed quickly. In this temperature range,

enzymes in the food react, leading to color changes.

3. Bottom heat, 700W, plus 2 steam generator elements, 2200W. 176°F

to maximum temperature in cavity. Condensate is evaporated. Less

steam released.

Regulating phase

1. Bottom heat, 700W.

Loading...

Loading...