Troubleshooting

6

6.12 Troubleshooting Without Fault Display

YASKAWA SIEPYAIH6B01A HV600 AC Drive Bypass Technical Reference 525

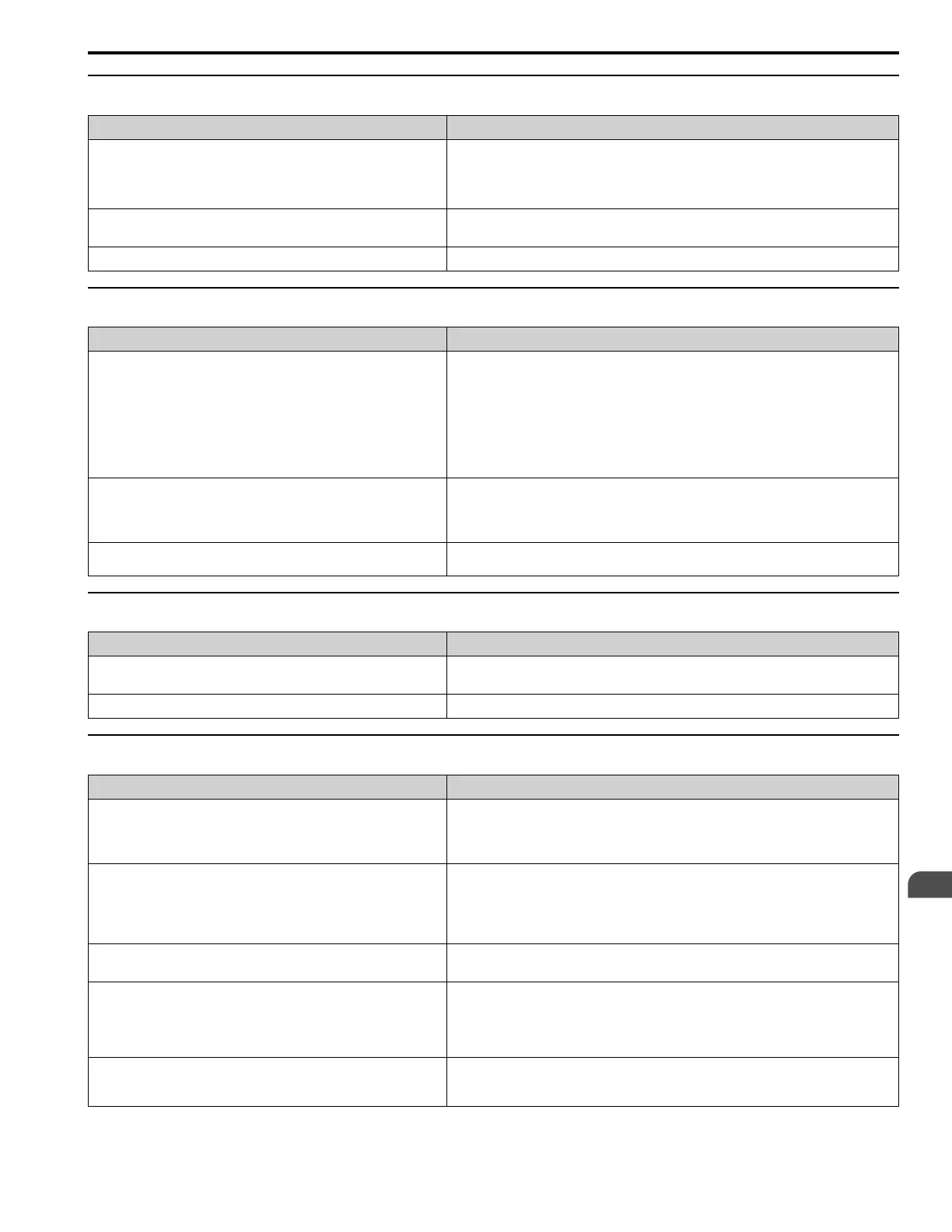

◆ Motor Rotation Causes Oscillation or Hunting

Causes Possible Solutions

The frequency reference is assigned to an external source, and there is electrical

interference in the signal.

Make sure that electrical interference does not have an effect on the signal lines.

• Isolate control circuit wiring from main circuit wiring.

• Use twisted-pair cables or shielded wiring for the control circuit.

• Increase the value of H3-13 [Analog Input FilterTime Constant].

The cable between the drive and motor is too long. • Do Auto-Tuning.

• Make the wiring as short as possible.

The PID parameters are not sufficiently adjusted. Adjust b5-xx [PID control].

◆ PID Output Fault

Causes Possible Solutions

There is no PID feedback input. • Examine the MFAI terminal settings.

• See if H3-02, H3-10 = B [MFAI Function Selection = PID Feedback] is set.

• Make sure that the MFAI terminal settings agree with the signal inputs.

• Examine the connection of the feedback signal.

• Make sure that b5-xx [PID Control] is set correctly.

Note:

If there is no PID feedback input to the terminal, the detected value is 0, which causes a PID

fault and also causes the drive to operate at maximum frequency.

The detection level and the target value do not agree. Use H3-03, H3-11 [Terminal A1, A2 Gain Setting] to adjust PID target and feedback signal scaling.

Note:

PID control keeps the difference between the target value and detection value at 0. Set the input

level for the values relative to each other.

Reverse drive output frequency and speed detection. When output frequency

increases, the sensor detects a speed decrease.

Set b5-09 = 1 [PID Output Level Selection = Reverse Output (Reverse Acting)].

◆ The Motor Rotates after the Drive Output Is Shut Off

Causes Possible Solutions

DC Injection Braking is too low and the drive cannot decelerate correctly. • Increase the value set in b2-02 [DC Injection Braking Current].

• Increase the value set in b2-04 [DC Inject Braking Time at Stop].

The stopping method makes the drive coast to stop. Set b1-03 = 0 or 2 [Stopping Method Selection = Ramp to Stop, DC Injection Braking to Stop].

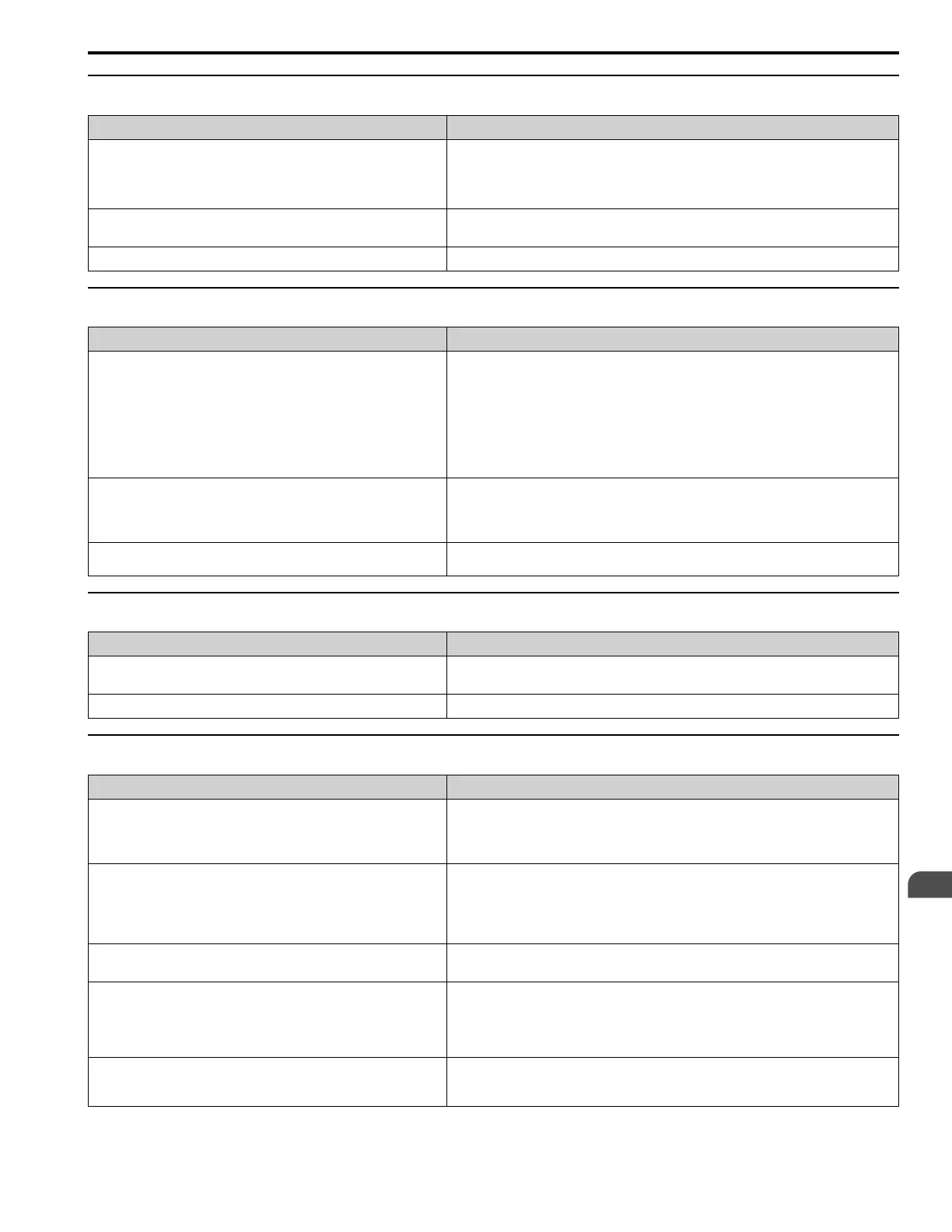

◆ The Output Frequency Is Lower Than the Frequency Reference

Causes Possible Solutions

The frequency reference is in the Jump frequency range. Adjust d3-01 to d3-03 [Jump Frequency 1 to 3] and d3-04 [Jump Frequency Width].

Note:

Enabling the Jump frequency prevents the drive from outputting the frequencies specified in the

Jump range.

The upper limit for the frequency reference has been exceeded. Set E1-04 [Maximum Output Frequency] and d2-01 [Frequency Reference Upper Limit] to the best

values for the application.

Note:

This calculation supplies the upper value for the output frequency:

E1-04 × d2-01 / 100

A large load triggered Stall Prevention function during acceleration. • Decrease the load.

• Adjust L3-02 [Stall Prevent Level during Accel].

L3-01 = 3 [Stall Prevention during Accel = Current Limit Method] has been

set.

1. Make sure that the V/f pattern and motor parameter settings are appropriate, and set them

correctly.

2. If this does not solve the problem, and it is not necessary to limit the current level of stall during

acceleration, adjust L3-02.

3. If this does not solve the problem, set L3-01 = 1 [Enabled].

The motor is rotating at this speed:

b2-01 [DC Injection/Zero SpeedThreshold] ≤ Motor Speed < E1-09 [Minimum

Output Frequency]

Set E1-09 < b2-01.

Loading...

Loading...